Woven Mesh Sieve adopts metal woven mesh to produce according to the national standard GB/T6003.1-1997. The basic size of the mesh is 2.36mm-0.038mm, in line with the international standard ISO3310-1: 1990 R20/3, R20, R40/3 series, the material is brass, tin bronze, stainless steel, the detection range is 2.36um-100um nickel-plated, mesh High precision, prevent mesh deformation, strong and wear-resistant.

Price: $10.00-$200.00/SetChat Now

National standard: GB/T6003.1-1997

Mesh size: 2.36mm-0.038mm

Diameter size: 100mm, 200mm, 300mm, 400mm, 450mm

Screen material: brass, tin bronze, stainless steel

Made of metal woven mesh, the basic size of the mesh is 2.36mm-0.038mm, widely used and cheap

Port:Any port in China (Mainland)or as you need.

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

Woven Mesh Sieve Woven Mesh Sieve is produced according to the national standard GB5330-2003, which is equivalently produced according to the international standard ISO9044-90. Its weaving structure has two kinds of plain weave and twill weave. Its wire mesh is made of high-quality brass, pewter bronze, and stainless steel. , pure nickel and other metal wire braided square mesh is divided into R10, 20, R40/3 series; mesh number 6.00 ~ 0.020mm (3 ~ 635 mesh/inch), diameter size is 100mm, 200mm, 300mm, 400mm or 450mm and 3, 8*, 12 or 18 inches, high precision sieves for laboratory sampling and particle size testing of materials.

| Screen Type | wire mesh |

| National standard | GB/T6003.1-1997 |

| use | Separation, classification, particle size determination |

| Application field | Agriculture, Biology, Chemistry/Plastics, Building Materials, Engineering/Electronics, Environment/Recycling, Food, Geology/Metallurgy, Glass/Ceramic, Medicine/Pharma |

| materials | Powders, bulk materials, suspensions |

| frame diameter | 100mm/200mm/300mm/400mm/450mm/500mm |

| grid size | 0.038mm-2.36mm |

Woven Mesh Sieve can be used as a sieve for material particle size analysis experiments within 0.038mm-2.36mm. It can be widely used in laboratories and scientific research institutions, and is often used in the diamond industry. Specific materials include aggregate, soil, grain, flour, millet, starch, flour, traditional Chinese medicine powder, soil, grain, coal powder, steel shot, glass powder, grain material, seasoning, etc.

It has a wide range of applications and is cheap in price. It is a high-precision screen and is mostly used in the diamond industry.

The screen frame is made of SUS304 (0Cr18ni9) stainless steel stretched and polished, with a wall thickness of 0.6 mm and a smooth surface.

The overall molding is strong and durable, without magnetism, and the screen mesh and screen frame are fixed by soldering without loosening. Can withstand high temperature below 300 degrees.

The mesh is precise, and the mesh of the same specification produced at different times is consistent because of the mesh mark. Metal wire woven test sieve, the mesh size of the square hole can reach 0.02 mm (20 microns), the mesh size of the triangular holes can reach 0.005 mm (5 microns), the sieve is woven according to the B6003.1-1997 standard. In line with international standards ISO3310-1: 1990 R20/3, R20, R40/3 series.

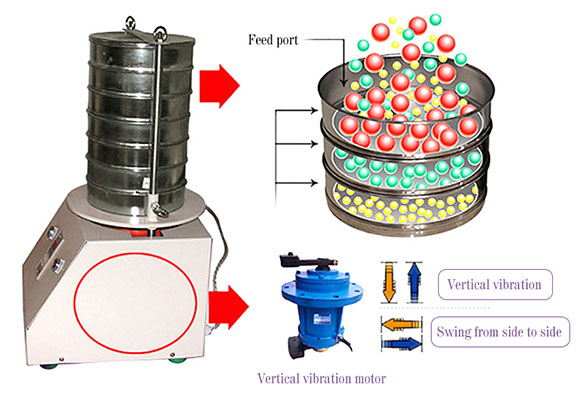

Woven Mesh Sieve uses YZU vertical vibrating motor as the vibration source of the whole machine. The vibration motor drives the upper vibrating plate to vibrate, and then transmits it to the Φ300 screen frame placed on the upper part of the vibrating plate through the vibrating plate. Sieve the material particles smaller than the pore size of the sieve to the lower sieve frame, so that only the same particle size material remains in each layer of the sieve frame, to achieve the separation of different particle sizes and determine the particle size composition of the material, so that the sieve frame The materials can be very effective for filtering, grading and screening purposes.

| serial number | name | Numerical value | unit |

| 1 | Can put sieve | 1~8 | layer |

| 2 | Screen diameter | φ200/φ100/φ75 | mm |

| 3 | Sieve particle size | 0.025~3 | mm |

| 4 | noise | less than 50 | dB |

| 5 | amplitude | 0~3 (stepless adjustment) | mm |

| 6 | electromagnetic vibration frequency | 3000 | times/min |

| 7 | Motor vibration frequency | 1400 | times/min |

| 8 | Dimensions | 435*350*720 | length*width*height |

| 9 | power supply | 220;50 | V;HZ |

| 10 | Total Weight | 55 | KG |

| mesh | Aperture(mm) | mesh | Aperture(mm) | mesh/td> | Aperture(mm) |

| 2 mesh | 12.5 | 45 mesh | 0.4 | 220 mesh | 0.065 |

| 3 mesh | 8 | 50 mesh | 0.355 | 240 mesh | 0.063 |

| 4 mesh | 6 | 55 mesh | 0.315 | 250 mesh | 0.061 |

| 5 mesh | 6 | 60 mesh | 0.28 | 280 mesh | 0.055 |

| 6 mesh | 4 | 65 mesh | 0.25 | 300 mesh | 0.050 |

| 8 mesh | 3 | 70 mesh | 0.224 | 320 mesh | 0.045 |

| 10 mesh | 2 | 75 mesh | 0.2 | 325 mesh | 0.043 |

| 12 mesh | 1.6 | 80 mesh | 0.18 | 340 mesh | 0.041 |

| 14 mesh | 1.43 | 90 mesh | 0.16 | 360 mesh | 0.040 |

| 16 mesh | 1.25 | 100 mesh | 0.154 | 400 mesh | 0.0385 |

| 18 mesh | 1 | 110 mesh | 0.15 | 500 mesh | 0.0308 |

| 20 mesh | 0.9 | 120 mesh | 0.125 | 600 mesh | 0.026 |

| 24 mesh | 0.8 | 130 mesh | 0.112 | 800 mesh | 0.022 |

| 26 mesh | 0.71 | 140 mesh | 0.105 | 900 mesh | 0.020 |

| 28 mesh | 0.68 | 150 mesh | 0.100 | 1000 mesh | 0.015 |

| 30 mesh | 0.6 | 160 mesh | 0.096 | 1800 mesh | 0.010 |

| 32 mesh | 0.58 | 180 mesh | 0.09 | 2000 mesh | 0.008 |

| 35 mesh | 0.50 | 190 mesh | 0.08 | 2300 mesh | 0.005 |

| 40 mesh | 0.45 | 200 mesh | 0.074 | 2800 mesh | 0.003 |

Dahan Woven Mesh Sieve manufacturers produce Woven Wire Sieves, stainless steel Woven Mesh Sieves, brass Woven Mesh Sieves and other types of woven mesh sieves, including 100mm, 200mm, 300mm, 400mm, 500mm, etc. The materials are brass, tin bronze, Stainless steel. Prices start as low as $150.

Diameter: 200mm

Price: $20.00-$200.00/Set

Screening particle size: 0.025-3mm

Price: $650.00 - $800.00/Set

Mesh: 10 mesh-200 mesh

Price: $18-$300/set

Aperture size: 2.36-0.038mm

Price: $5-$500/Set

Test Sieve Shaker is an instrument for detecting and analyzing the particle size structure and particle size distribution of 2kg of material in the test sieve. Test Sieve Shaker Pro...

Pharmacopoeial sieves (standard pharmacopoeial sieves) refers to the sieves used for pharmaceutical production according to the national uniform specifications stipulated in the Pha...

Application of wet sieve test screening material

In many cases, wet sieve test sieving, despite the inconveniences that come with it, has clear advantages over dry sieving. For example, the material to be tested may have been susp...

What is the difference between wet sieving and dry sieving

The sieving test is divided into wet sieving test and dry sieving test, so what is the difference between wet sieving and dry sieving? difference Wet sieving test Dry sieving test i...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap