Wednesday April-09 2025 17:34:26

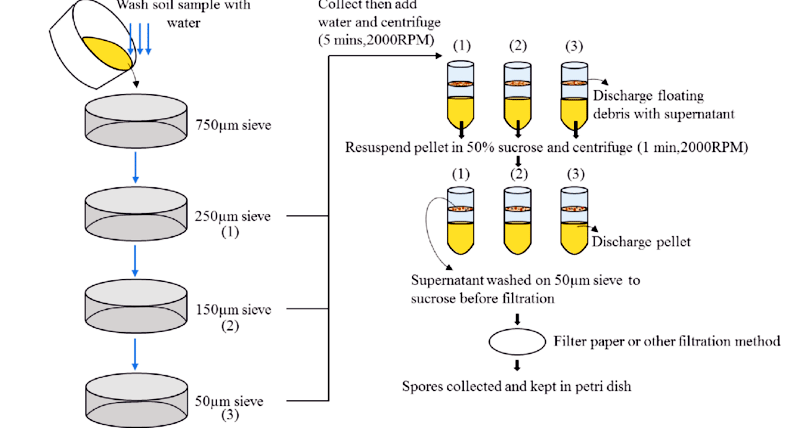

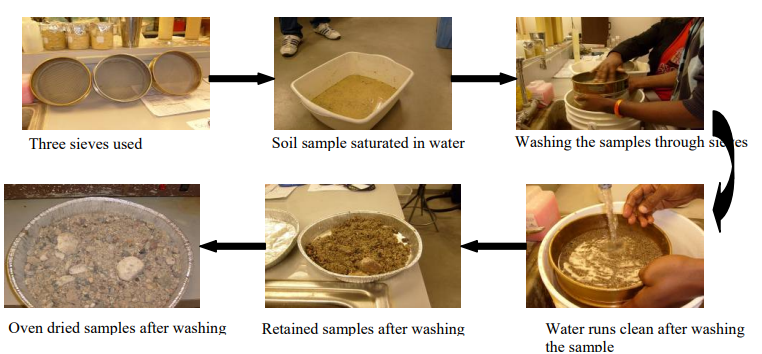

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively separate fine particles, sticky materials, or where liquid bound to particles needs to be removed. Its core principle is to use a combination of water flow flushing and vibrating screens to classify the mixture by particle size.

The material to be screened is mixed with a liquid to form a slurry, which is then passed through a vibrating screen. The main roles of the liquid medium are:

Dispersion: Helps disperse fine or sticky particles that are easy to agglomerate and improves separation efficiency.

Cleaning: The flowing liquid flushes the screen to prevent fine particles from clogging the mesh and keep the screen clean.

Medium role: The liquid acts as a carrier to help fine particles pass through the screen more smoothly.

Liquid medium role: Water or other liquids can reduce the adhesion between particles, prevent fine particles from agglomerating, and carry fine particles through the screen.

Mechanical vibration: The screen promotes particle dispersion under high-frequency vibration and improves screening efficiency, especially for fine particles (such as materials <75μm).

|

Features |

wet sieving process |

dry sieving process |

|

Image |

|

|

|

Applicable particle size |

finer (up to several microns) |

usually >75μm |

|

Processing capacity |

lower (due to water medium limitation) |

higher |

|

Environmental protection |

no dust, but wastewater |

dust needs to be controlled |

The process of wet sieving process mainly includes three parts: First, the material is mixed with water into slurry, and a dispersant is added if necessary. Second, the slurry passes through the vibrating screen, and the water flow washes the fine particles through the screen, and the coarse particles remain on the screen. Finally, the screened material (slurry containing fine particles) needs to be precipitated, filtered or centrifuged to recover solids.

The selection of Wet sieving process needs to comprehensively consider the material properties, particle size requirements and subsequent processing costs, especially in fine powder and high purity applications.

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis and quality control of corn grits...

What Is An Electromagnetic Sieve Shaker?

Electromagnetic sieve shaker is a screening equipment used for testing and laboratory research. It is often used to screen and classify small batches...

Test sieve shaker is a laboratory equipment used for particle screening and classification, also known as laboratory shaker or laboratory vibrating...

Phosphate Test Sieve is an experimental tool used to screen different particle sizes in phosphate samples and detect the phosphate...

Vitamin powder slapping screen

Vitamin powder slapping screen is a device used to screen vitamin powder. It screens materials through mechanical vibration and slapping...

Stainless steel sieve shaker model features

Stainless steel sieve shaker is an important tool for particle size analysis. Its model features are mainly reflected...

Apr 09, 2025

What is the wet sieving process?

Wet sieving is a screening process assisted by liquid, mainly used to more effectively separate fine ...

Apr 09, 2025

Stainless Steel Sieve Shaker Model Features

Stainless steel sieve shaker, an essential tool for particle size analysis, is characterized by its h...

Mar 25, 2025

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis...

Mar 25, 2025

Laboratory Lactose Stainless Steel Test Sieve

Laboratory lactose stainless steel test sieve is a device used to accurately determine the size distr...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap