Tuesday December-24 2024 13:53:21

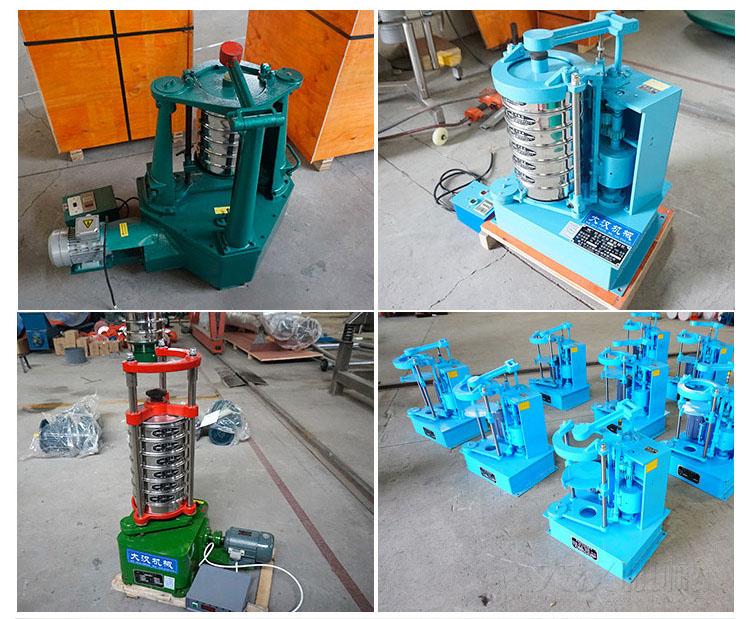

Rotap sieve shaker has two vibration modes of slapping and reciprocating at the same time. The material is fast and the material is not easy to block. It is suitable for the inspection of the particle size composition of ordinary abrasives and the production classification and particle size composition inspection of superhard materials.

Slap times: 156±3 times/min Slap height: 38±6 mm

Number of rotations: 290±6 times/min Rotation stroke: 25mm

Rotap sieve shaker can sieve products with various characteristics. It is suitable for the inspection of the particle size composition of ordinary abrasives and the production classification and particle size composition inspection of superhard materials. It is also widely used in the scientific research and production laboratories of geology, metallurgy, powder, chemical industry, construction cement, medicine, national defense and other departments to screen materials. detection. The slapping screen is a reasonable innovation based on the original slapping standard vibrating screen machine, and the structure of the original frame is improved. The structure is more compact, the body weight is reduced, the product is more durable, light and convenient, the maintenance is simpler, and the accessories are easy to repair and purchase.

1. High screening efficiency: This screening method has two vibrations of reciprocating and slapping vibration at the same time during screening, which will not block the screen surface, fast feeding, and high screening accuracy.

2. Accurate transmission and good consistency: due to the use of gears to drive the synchronous belt transmission, the speed ratio is accurate, and there will be no speed drop phenomenon of the general V-belt (3% drop rate of the V-belt), so that the screening at the same time every time The movement is consistent, and the equipment is equipped with a digital timer, which will automatically stop when the time is set.

3. Long service life: Since the two gears are not in direct contact, they will not wear out, the contact adaptability between the timing belt and the size is good, and the service life is long. You only need to replace the timing belt during maintenance. Accurate and convenient, the rotating part adopts bearings (standard parts), which are not easy to wear, low cost and easy to replace.

4. Cleanliness: Since this transmission method does not require refueling, the maintenance cost is reduced and the environment is protected, which is very beneficial to the cleanliness required in the production process.

The Rotap sieve shaker uses the vibration motor to drive the gear to the main shaft according to the synchronous belt. After the speed is adjusted by the gear, the main shaft rotates according to the specified speed ratio. The two groups of test sieves from large to small shake from side to side, and at the same time, the main shaft drives the jumping lever gear to rotate. After the gear shifts, the first lever gear hits the jumping lever through the cam. The material in the sieve reciprocates and vibrates up and down, so that the raw material particles below the mesh of the test sieve are sieved into the lower test sieve, and so layer by layer, so that only the same particle size raw materials are left in each test sieve. To achieve the peeling of different particle sizes and to clarify the particle size composition of this material.

How does Rotap Sieve Shaker work?

Rotap sieve shaker can screen products with various characteristics. It is suitable for the inspection of the particle size composition of ordinary abr...

Five Advantages of Rotap Sieve Shaker

Rotap Sieve Shaker is mainly composed of machine base, sieve and transmission mechanism. It can be equipped with special fixtures, which can be used...

The Rotary Sieve Shaker plays the role of a testing instrument in the laboratory. When the Rotary Sieve Shaker sieves the material, there is a hammer...

What is the cost of rotap sieve shaker?

The price of a rotap sieve shaker ranges from a few hundred dollars to several thousand dollars. The cost depends on the brand, model, capacity...

Dec 24, 2024

What is a grain sieve? Grain Sieves can screen millet, wheat, sorghum and other grains from 20m to 12...

Dec 23, 2024

Slap-type standard vibrating screen machine

Slap-type standard vibrating screen machine, also known as slap-type vibrating screen, is one of the ...

Dec 20, 2024

Laboratory powder sifter, also known as a laboratory sieve shaker or powder sieve, is a specialized p...

Dec 13, 2024

Laboratory electric vibrating screen machine

Laboratory electric vibrating screen machine is a device specially used for screening and parti...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap