The Wet sieve test can be used to remove fines from materials that may be difficult to sieve prior to drying and normal testing of samples. For dry sieving difficult materials. The Wet sieve test is used for materials with the following properties:

almost insoluble in water

Not affected by water; for example, solids that expand when wet do not work

unchanged when heated to 110°C

$656.00 - $975.00 / Sets Chat Now

Diameters: 3", 8", 12"

Mesh size: 20 microns-5 mm

Height: 4 inches, 8 inches

1.For samples with high concentrations of fine particles or samples whose particles are not easily broken down by mechanical shaking

2.Can be sieved to 0.025-3mm, timed shutdown

3.Material: Brass/Stainless Steel

4.Small size, easy to move.

Port:Any port in China (Mainland)or as you need.

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

Wet Sieve Test is a procedure to detect particle size distribution or gradation. The Wet sieve test is used to separate coarse-grained materials from water or other liquids before drying, testing and analyzing the samples, and it is also used to prepare granular samples for particle size analysis by removing fines that may hinder the separation process. For example: removing fine particles that hinder separation, break up clumps or eliminate static electricity.

Wet sieve test analysis is required when sieve analysis of difficult dry materials is not possible.

Wet sieve test sieve analysis or gradation testing determines the size distribution of particles in a given sample. It can be determined whether the design and production requirements are met according to the data analyzed by the wet sieve test.

Wet sieving can be used to remove fine material that may be difficult to sieve before the sample is dried and tested normally. Wet sieving is suitable for solids that are virtually insoluble in water and unaffected by water; for example, solids that swell in water do not work and remain unchanged when heated to 110°C.

1. Evaluate the suitability of raw materials: Screening tests can help evaluate whether the particle size of raw materials meets production requirements.

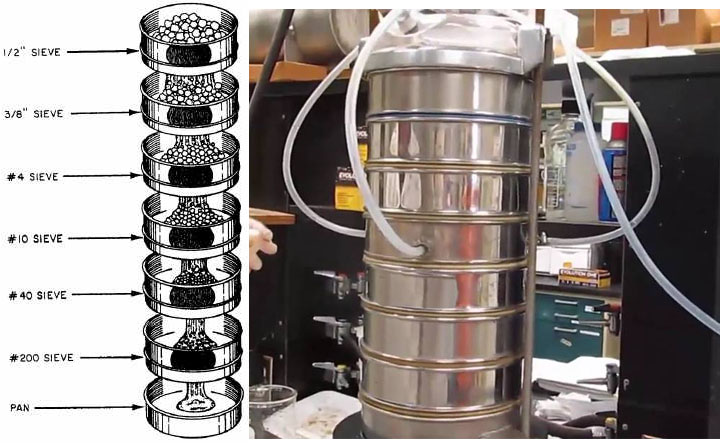

2. Determine the particle size distribution of materials: By screening the materials using a series of sieves with different mesh sizes, the materials can be divided into different grades according to the particle size.

3. Control product quality: The particle size of the product directly affects its performance and quality. Through screening tests, it can be ensured that the particle size of the product meets the specified standards and requirements.

4. Study the properties of materials: Screening tests can be used to study the physical properties of materials, such as particle shape, surface roughness, etc.

The wet sieving test can be used to remove fines from difficult to sieve materials prior to testing and analyzing normal sample materials, suitable for materials that require wet processing, high concentrations of fines, agglomerates, sticky materials.

Typical applications for Wet Sieve Test

Soil and mineral aggregates with high fines content

Fragile but insoluble materials such as coal or other minerals

light powder

agricultural soil with a high clay content

contaminated soil (brownfields)

clay suspensions

river sediments

sludge and glazes

kaolin and fillers

abrasives

micro granulations

Wet Sieve Test can be divided into two kinds of manual wet sieve test and wet sieve test screening machine in particle size analysis.

Manual Wet Sieve Test: Dry the sample to constant weight and weigh to the nearest 0.1 g

If your sample mixes easily with water:

Place the sample on the test sieve and wash it back and forth with a gentle stream of water from the hose (make sure no sample is lost)

The entire sieve containing wet material should be dried in the oven if possible. It is critical that the temperature does not exceed 230°F (110°C)

After the material has dried thoroughly, the material should be weighed and repeated on the next coarser sieve (**Drying time depends on the characteristics of the material and should be determined by a series of weight checks at intervals until no significant change occurs)

Weigh your sample and analyze it

Wet Sieve Test Screening Machine: Use the wet sieve kit provided by Dahan to complete the material particle size analysis on the wet sieve test sieving machine. Put the sample to be tested into the uppermost sieve frame, fix the sieve group on the wet sieve test sieving machine, add water through the added pipe, and rinse while sieving.

1. Handle materials with high concentration of fine particles and difficult to decompose.

2. Viscous and easy-to-caking materials can be used for materials that cannot be processed by dry screening.

3. Precise screening, can screen 0.025-3mm.

4. It can be turned off at a fixed time. The time is adjustable from 1s to 99h to ensure the repeatability and consistency of the experiment.

5. Materials can be classified into various specifications, and can accurately separate 8 particle segments at the same time.

When performing the Wet Sieve Test, the vibration motor is used as the vibration source, and the vibration of the vibration motor is used to drive the vibration of the screen machine, and the vibration is transmitted to the screen frame through the machine base, and water is added to wash while vibrating, so that the material particles smaller than the mesh are dropped. Enter the lower sieve frame for sieving, and only the materials with the same particle size are left in the same layer of sieve frame, so that the separation of different particle sizes can be quickly realized and the particle size composition of the material can be determined.

The below table shows the detailed data of different models of wet sieve for your reference.

| NO. | Name | Unit | Parameter |

| 1 | frame diameter | mm | φ200 |

| 2 | the number of layer | s | 1~8 |

| 3 | sieve size | mm | 0.025-3 |

| 4 | vibrating amplitube | mm | 1~4 |

| 5 | vibration frequency | n/min | 1440 |

| 6 | power supply | V;HZ;KW | 220;50;0.12 |

| 7 | outside dimension | LWH | 350*350*(300+n*56) |

| 8 | machine weight | kg | 36 |

| 9 | time alarm | s | 999 |

| 10 | noise | db | Less than 50 |

When dry sieving cannot produce an adequate degree of sample separation

When testing sample that contain little gravel-sized materials

When silt and clay removal is needed

Pre-testing

Mix sample materials with water until it becomes a suspension

Prepare a stack of sieves that are drenched

Place gaskets between each individual sieve

Place wet washing lid on the top of the sieves and wet washing receiver (with outlet) on the bottom

Establish the flow of water

Wet Sieve Test

1. Pour the material into the top screen frame.

2. Depending on the size of the sample, turn on the wet sieve test for 5-10 minutes.

3. Turn on the water supply.

4. Observe the liquid at the outlet, once the liquid is clear, turn off the water and shaker.

5. Collect the material retained on each sieve.

Wet Sieve Test can determine the particle distribution of coarser and larger sizes of materials, and the distribution of finer particles using the hydrometer method, the following is an example of aggregate:

| Opening sieve size(mm) | Mass retauned on each sieve(g) | Cumulative mass(g) | Percent finer*(%) |

| 10 | 0 | 0 | 100 |

| 6.3 | 18.36 | 18.36 | 98.23 |

| 5 | 66.61 | 84.97 | 91.79 |

| 3.55 | 203.67 | 288.64 | 72.11 |

| 2 | 109.5 | 398.14 | 61.53 |

| 1.18 | 61.42 | 459.56 | 55.60 |

| 0.600 | 69.09 | 528.65 | 48.92 |

| 0.425 | 28.07 | 556.72 | 46.21 |

| 0.3 | 25.67 | 582.39 | 43.73 |

| 0.212 | 20.02 | 602.41 | 41.80 |

| 0.15 | 16.79 | 619.2 | 40.17 |

| 0.063 | 20.92 | 640.12 | 38.15 |

| pan | 394.88 | 1035 | 0.00 |

Wet sieve test: It is used for particles above 75μm and below 4.75mm, and can separate fine and coarse particles of materials and water or other liquids. The samples contained very fine powders that easily agglomerated. Dry sieve tests can lead to clogged sieves, in cases where dry sieves are difficult to analyze, wet sieve tests are used.

Wet sieve test is suitable for samples containing high concentrations of fine particles or samples whose particles are not easily broken by mechanical shaking. For example, clays, such as clay or silt, can clump together to form larger particles that cannot pass through the mesh.

Dry sieve test: It can be used for particle size structure analysis and detection of granular and powdery materials with a diameter of 4.75mm and above under dry conditions.

Conditions for selecting dry sieve test: the material is dry and has good free flow, and only needs to be shaken or tapped to separate the material. Dry sieve test is commonly used in chemical, food and beverage, pharmaceutical and other industries.

| Project | Wet Sieve Test | Dry Sieve Test |

| Separation medium | Water or other liquids | Air |

| Applicable materials | Easy to agglomerate, fine powder, sticky materials | Dry, granular materials with good fluidity |

| Advantages | Prevent clogging, high precision | Simple operation, fast speed |

| Disadvantages | Many operation steps, need to dry samples | Easy to clog, not suitable for fine powder and sticky materials |

| Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) |

| 2 | 13 | 26 | 0.71 | 90 | 0.16 | 260 | 0.06 |

| 3 | 6.5 | 28 | 0.63 | 100 | 0.154 | 280 | 0.055 |

| 4 | 5 | 30 | 0.6 | 110 | 0.14 | 300 | 0.054 |

| 5 | 4 | 32 | 0.55 | 115 | 0.13 | 320 | 0.048 |

| 6 | 3.2 | 36 | 0.5 | 120 | 0.125 | 325 | 0.045 |

| 7 | 2.8 | 40 | 0.45 | 130 | 0.111 | 350 | 0.041 |

| 8 | 2.5 | 45 | 0.4 | 140 | 0.105 | 360 | 0.4 |

| 9 | 2.2 | 50 | 0.355 | 150 | 0.1 | 400 | 0.0385 |

| 10 | 2 | 55 | 0.315 | 160 | 0.098 | 500 | 0.03 |

| 12 | 1.6 | 60 | 0.3 | 180 | 0.09 | ||

| 14 | 1.43 | 65 | 0.25 | 190 | 0.08 | ||

| 16 | 1.25 | 70 | 0.22 | 200 | 0.075 | ||

| 18 | 1 | 75 | 0.2 | 220 | 0.07 | ||

| 20 | 0.9 | 80 | 0.18 | 240 | 0.065 | ||

| 24 | 0.8 | 85 | 0.17 | 250 | 0.063 |

| NO. | Name | Unit | Parameter |

| 1 | frame diameter | mm | φ200 |

| 2 | the number of layer | s | 1~8 |

| 3 | sieve size | mm | 0.025-3 |

| 4 | vibrating amplitube | mm | 1~4 |

| 5 | vibration frequency | n/min | 1440 |

| 6 | power supply | V;HZ;KW | 220;50;0.12 |

| 7 | outside dimension | LWH | 350*350*(300+n*56) |

| 8 | machine weight | kg | 36 |

| 9 | time alarm | s | 999 |

| 10 | noise | db | Less than 50 |

1. The screening accuracy is accurate and the efficiency is high.The whole machine is exquisitely designed, light in weight, small in size, and easy to place and move.

2. It has a wide range of applications and can be used for particle size classification and particle size analysis of slurries and powders.

3. It can screen to 0.025-3mm.There are many material classifications, and 8 particle segments can be accurately separated at the same time.

4. The screening time can be set by yourself and automatically shut down. The time is adjustable from 1s to 99h to ensure the repeatability and consistency of the experiment.

Detection range: 0.075mm-100mm

Price: $20.00 - $200.00/set

Screening particle size: 0.025-3mm

Price: $650.00 - $800.00/Set

Laboratory Sieve Shaker Machine

Measuring range: 20µm-125mm

Price: $600.00 - $980.00/Set

Screening particle size: 0.025mm-3mm

Price: $538.00 - $925.00/Set

In the international standard classification, Wet Sieve Test involves textile products, chemical products, construction materials, soil quality, soil science, agricultural machinery...

Application of wet sieve test screening material

In many cases, wet sieve test sieving, despite the inconveniences that come with it, has clear advantages over dry sieving. For example, the material to be tested may have been susp...

What is the difference between wet sieving and dry sieving?

The sieving test is divided into wet sieving test and dry sieving test, so what is the difference between wet sieving and dry sieving...

How do you perform wet sieving?

Wet sieving test is a method of separating coarse and fine particles of materials with water or other liquids, which can remove fine particles...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap