Tuesday March-25 2025 14:55:11

Vitamin powder slapping screen is a device used to screen vitamin powder. It screens materials through mechanical vibration and slapping action. It is particularly suitable for processing fine particles or powder materials. It uses the screen to classify materials according to particle size. It is often used to remove impurities, separate different particle sizes or ensure the uniformity of vitamin powder.

1. Remove impurities: remove foreign matter mixed in during the production process (such as packaging fragments, small lumps).

2. Particle size classification: ensure that the particle size of the vitamin powder is consistent (such as controlled at 100-200 mesh) to avoid affecting the weighing accuracy due to uneven particle size.

3. Deagglomeration: break up slight lumps to ensure fluidity and facilitate subsequent transportation and packaging.

The screen body is driven by a motor to produce a dual motion of horizontal rotation and vertical slapping. The vitamin powder is thrown up and sieved on the screen surface. Fine vitamin powder particles pass through the sieve holes, and large particles or impurities are intercepted.

Vitamin powder is a fine, light, and easy to float material. The following problems may be encountered during the screening process:

✅Extremely fine particles, easy to block the screen

✅Strong adhesion, easy to agglomerate

✅Light powder, easy to raise dust

✅High-precision screening is required to ensure compliance with pharmaceutical or food industry standards

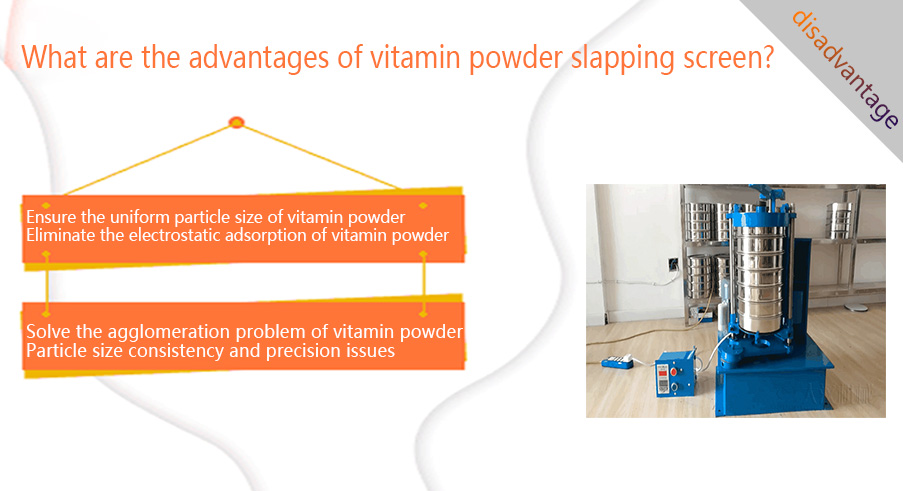

1. Ensure the uniform particle size of vitamin powder: Vitamin powder slapping screen can screen vitamin powder in multiple layers. Vitamin powder starts from the upper screen and is gradually screened from coarse to fine, so that powders of different particle sizes are separated at different levels.

2. Eliminate the electrostatic adsorption of vitamin powder: In the parts in contact with vitamin powder, such as screens, hoppers, etc., anti-static materials are selected to quickly remove static electricity, reduce the impact of static electricity, and allow the powder to pass through the screen smoothly.

3. Solve the agglomeration problem of vitamin powder: The combined action of slapping and vibration can effectively break the agglomerates of vitamin powder, disperse the agglomerated powder, and facilitate screening. The slapping action causes the agglomerates to be broken by impact force, and the vibration causes the powder to continuously jump and roll on the screen surface, further promoting the separation of agglomerates.

4. Particle size consistency and precision issues: Vitamin powder slapping screen supports customized screen mesh (such as 100 mesh, 150 mesh, 200 mesh) to ensure that the particle size distribution meets the requirements. Its mechanical structure design ensures consistent amplitude and frequency, and stable screening results.

|

Parameter |

Typical value |

Description |

|

Screen diameter |

200mm-1000mm |

200mm for small experiments, larger for industrial use |

|

Screen mesh number |

20 mesh-400 mesh |

100-200 mesh is commonly used for vitamin powder |

|

Frequency |

1400 times/minute |

Ensure efficient screening without blocking the screen |

|

Power |

0.25kW-1.5kW |

Adjust according to the size of the screen surface and the number of layers |

|

Material |

Stainless steel |

Meet hygiene requirements |

The particle size of vitamin powder varies depending on the preparation process (such as spray drying or crystallization process).

Coarse screening (removing large particles): 30 mesh (500μm)-60 mesh (250μm)

Medium particle size analysis: 100 mesh (150μm)-200 mesh (75μm), suitable for most vitamin powders.

Fine screening: 325 mesh (45μm)-400 mesh (38μm), suitable for ultrafine powder or high-precision experiments.

1. Vitamin premix production: The multi-layer screen of the vitamin powder slapping screen simultaneously separates vitamin components of different particle sizes (such as vitamin A microcapsules and excipients) to improve mixing uniformity.

2. Recycled dust treatment: Vitamin powder slapping screen re-screens and reuses the vitamin dust generated by the packaging line to reduce waste (recovery rate>98%).

3. Laboratory research and development: The small slapping screen of the vitamin powder slapping screen (screen diameter 200mm) is used for small batch sample particle size analysis to support R&D formula optimization.

Vitamin powder slapping screen uses vibration and slapping actions to make the vitamin powder pass quickly on the screen to achieve powder screening and grading. This equipment plays an important role in the vitamin production process, helping to optimize the production process and improve product quality. According to specific production needs and material characteristics, you can choose a suitable vitamin powder slapping screen for application.

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis and quality control of corn grits...

What Is An Electromagnetic Sieve Shaker?

Electromagnetic sieve shaker is a screening equipment used for testing and laboratory research. It is often used to screen and classify small batches...

Test sieve shaker is a laboratory equipment used for particle screening and classification, also known as laboratory shaker or laboratory vibrating...

Phosphate Test Sieve is an experimental tool used to screen different particle sizes in phosphate samples and detect the phosphate...

High precision subdivision test sieve

High precision subdivision test sieve is a device used in the laboratory to perform fine particle size analysis on granular and powdery...

Mar 25, 2025

Vitamin powder slapping screen

Vitamin powder slapping screen is a device used to sieve vitamin powder. It achieves sieving through ...

Mar 07, 2025

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis...

Mar 06, 2025

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch productio...

Mar 05, 2025

Ultrasonic test sieve for wheat flour

Ultrasonic test sieve for wheat flour is a special device that combines ultrasonic technology with tr...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap