Ultrasonic Test Sieve is a device that uses ultrasonic sensors and controllers to screen materials; ultrasonic sensors can accurately measure the physical properties of materials, and the controller can regulate the accuracy and speed of screening according to the set parameters.

Screen frame diameter: 75mm/100mm/200mm/300mm Chat Now

Mesh: 600 mesh

Screening particle size: 0.025-3mm

Feed amount: 500g

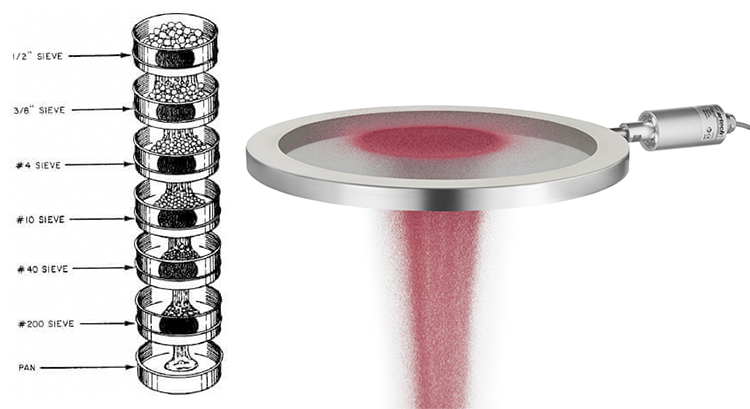

Screen frame layers: 1-7 layers

Timing: 0-99 points

1. The screening accuracy can reach more than 95%, and it can easily handle high-fine powder materials of more than 300 mesh, and can even reach 600 mesh or 500 mesh.

2. Made of 304 stainless steel and polished, it has the characteristics of anti-rust, high temperature resistance and non-magnetic.

3. The screening speed is several times faster than that of ordinary vibrating screens, the output can be increased by 0.5-10 times, and it can work continuously for 24 hours to reduce downtime.

Ultrasonic Test Sieve is an efficient screening tool that uses the principle of ultrasonic vibration to screen materials. It uses high-frequency vibration to accurately separate materials, and the screening efficiency is as high as 99%. At the same time, Ultrasonic Test Sieve also has the advantages of high screening precision, fast screening speed, low noise and easy cleaning. It is widely used in food, chemical, pharmaceutical, building materials and other industries, and is especially suitable for screening high-precision materials that are prone to static electricity.

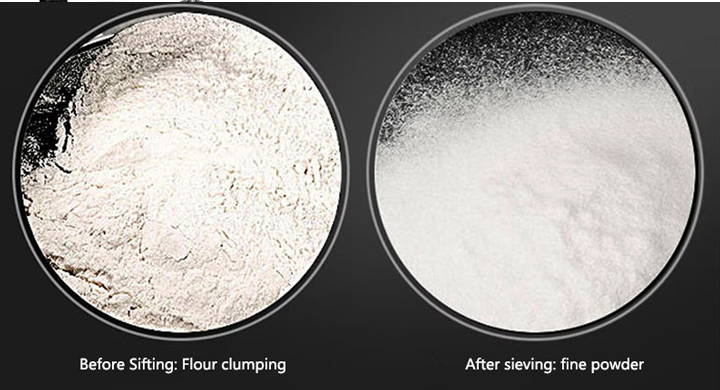

Ultrasonic Test Sieve is a device that uses the vibration energy of ultrasonic waves to screen and separate materials. Through the superposition of high-frequency vibration and ultrasonic waves, it achieves efficient screening of materials. At the same time, the introduction of ultrasound has solved screening problems such as clogging of mesh holes caused by agglomeration, static electricity, and strong adsorption. Secondly, the vibration effect of ultrasound can cause strong impact force on the material during the screening process, promoting rapid movement of the material on the sieve and effectively improving the screening effect.

Ultrasonic Test Sieve can be used in material research, pharmaceutical industry, food industry, chemical industry and other fields. In the pharmaceutical industry, ultrasonic test sieves can be used to sieve pharmaceutical raw materials, excipients and preparations; in the food industry, they can be used to sieve flour, powdered sugar, condiments, etc.; in the chemical industry, they can be used to sieve various chemical raw materials .

1.Laboratory research: In the development process of new materials, ultrasonic test sieves can be used to screen material particles of different sizes, providing accurate data support for the development of new materials. They can also screen and classify catalysts, optimize reaction conditions.

2.Industrial production: It is widely used in the fields of pharmaceuticals, food, chemical engineering, metallurgy, etc. Ultrasonic test screens can be used to screen raw materials, intermediates, and finished drugs, ensuring the uniformity and particle size of drug particles meet pharmacopoeia standards. It can also effectively remove impurities and clumps, improving the quality and taste of the product. There are various types of chemical products with different requirements for particle size. Ultrasonic test screens can be used to screen various chemical raw materials and products, such as pigments, dyes, coatings, plastic particles, rubber powders, etc., to meet the requirements of different production processes and product quality.

3.Quality inspection: Ultrasonic test sieves can be used for particle size analysis and impurity detection. By screening and weighing particles with different particle size ranges, the particle size distribution of materials can be accurately determined. Impurities can also be separated from materials through screening, and analyzed and detected to promptly identify problems in the production process.

1.Soft screening: Ultrasonic vibration is relatively soft and does not cause strong impact and friction on the material, avoiding material breakage, deformation, or changes in its physical and chemical properties due to the screening proce ss, and maximizing the preservation of the original characteristics and quality of the material.

2.High screening accuracy: Through the action of high-frequency vibration waves, the material particles produce finer vibrations on the sieve, thereby achieving high-precision screening. This vibration effect can disrupt the agglomeration phenomenon between material particles, making it easier for particles to pass through the sieve holes.

3.Strong adaptability: Ultrasonic test screens have a wide range of adaptability and can handle various types of materials. Whether it is powder, particle or liquid, ultrasonic test screens can meet screening requirements by adjusting vibration parameters and screen structure.

4.Reduce material layering: In the ordinary screening process, materials are prone to layering on the screen surface, making it difficult for fine particles to contact the sieve holes. Ultrasonic vibration can break this layering, making the material particles more evenly distributed on the sieve surface, increasing the chance for fine particles to pass through the sieve holes, and thus improving the screening efficiency.

The working principle of Ultrasonic Test Sieve is to place the particle sample on the sieve and vibrate transversely through ultrasonic waves to cause friction between the particles and the sieve, so as to realize the screening, separation and particle size analysis of particles.

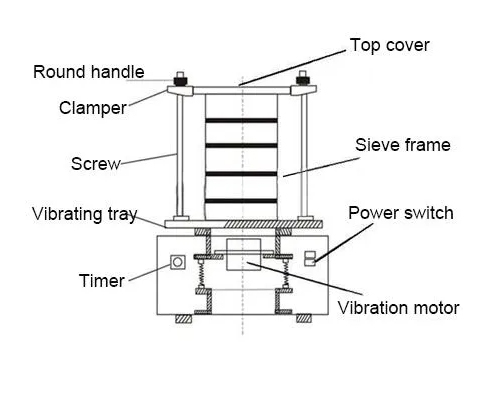

Specifically, Ultrasonic Test Sieve is mainly composed of core components such as resonators, generators, sensors, screen frames and screens. Among them, the resonator is responsible for oscillating the screen, the sensor senses the movement of particles on the screen, establishes a dynamic model, and the generator adjusts the amplitude, frequency and vibration mode to realize the adjustment of screening accuracy. When the ultrasonic wave acts on the particle sample, due to the high energy and high frequency of the ultrasonic wave, the interaction force between the particle and the screen will be increased, and the friction force and mutual bonding force between the particles will also be reduced, so that It can be screened with smaller sieve holes, so as to obtain more accurate particle distribution and particle size analysis results.

| sequence | name | unit | numerical value |

| 1 | Screen frame diameter | mm | Φ200 |

| 2 | Number of screen frame layers | Layer | 5 |

| 3 | Vibration frequency | N/min | 1400 |

| 4 | Vibration amplitude | mm | 1-4 |

| 5 | Excitation force | kn | 2 |

| 6 | Chassis level | mm | ≤0.6 |

| 7 | electric motor(power) | kw | 0.18 |

| electric motor(speed) | R/min | 1400 | |

| 8 | Overall dimensions | mm | 370*350*350 |

| 9 | Timing time | min | 1-5 |

1.Preparation: Carefully inspect the appearance and internal components of the sieve box to ensure there is no deformation or damage. Confirm all parts are securely connected and there is no looseness. Place the ultrasonic test sieve steadily on a solid, level workbench.

>2.Installation and Loading Install the selected sieve cloth into the corresponding sieve frame. According to the sieve cloth's mesh size from large to small, place the sieve frames on the device's frame base from bottom to top. Slowly pour the material to be sieved into the top sieve frame, trying to distribute it evenly.

3.Operation of Ultrasonic Test Sieve: Based on the characteristics of the material and the sieving requirements, set the appropriate ultrasonic frequency and power through the adjustment knob or on the ultrasonic power supply. For finer or more viscous materials, the ultrasonic power and frequency can be appropriately increased.

4.End of Sieving After the sieving is completed, first press the stop button on the ultrasonic power supply, then turn off the main power switch of the device, and un the power cord.

Ultrasonic test sieve is an efficient and high-precision screening equipment that has been widely used in many industries. It is especially suitable for classifying and screening fine powder in laboratories. With the continuous development of technology, the performance of ultrasonic test sieves will continue to improve, providing more efficient and reliable solutions for production in all walks of life.

What is the cost of RoTap sieve shaker?

The price of a rotap sieve shaker ranges from a few hundred dollars to several thousand dollars. The cost depends on the brand, model, capacity, and features of the sieve shaker. Ge...

Standard sand sieve for cement testing

Cement Standard sand sieve is mainly used in various laboratories, laboratories, item screening, sieving, grading and other inspection departments to accurately determine the partic...

The sieve analysis test for sand is a method used to determine the particle size distribution and analysis of sand; it is commonly used for sand and gravel, and the visible sand is ...

What is sieve analysis test for cement?

Sieve analysis test for cement is an essential test carried out to determine the particle size distribution of cement particles. It involves the separation of cement particles into ...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap