Ultrasonic Sieve Shake is equipped with an ultrasonic device, which has no blocking network and precise detection, which can solve the problem of blockage of materials with strong adsorption, easy agglomeration, high static electricity, high density, and light specific gravity; equipped with a time relay, it can realize 0-99 minute timing.

Price: $20.00-$3,680.00/SetChat Now

Screening particle size: 0.025-3mm

Screen frame diameter: 75mm/100mm/200mm/300mm

Screen frame layers: 1-7 layers

Timing: 0-99 points

Materials: flour, medicine powder, coal slime, diamond, graphite, abrasive, plastic powder, calcium carbonate

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

Ultrasonic Sieve Shaker, also known as ultrasonic test sieve, is an ultrasonic screening system installed on the basis of ordinary Sieve Shake, which excites the screen with continuously changing ultrasonic frequency, so that the mesh is not blocked, and it is easier to screen powder, which can be used for <300μm fine powder fine screening and classification; detection accuracy is higher and more accurate, can effectively solve the problem of network blockage caused by strong adsorption, easy caking, high static electricity, high density, light specific gravity and other materials screening; Ultrasonic Sieve Shake is equipped with The time relay can realize the timing of 0-99 minutes, automatic timing stop, which can ensure the standardization of detection. The whole machine is made of 304 stainless steel, which is anti-rust, high temperature resistant and non-magnetic.

With ultrasonic sieve support, the waves are evenly distributed and stimulate the test sieve at a continuously changing frequency. This has several efficiency-enhancing effects:

1. The high frequency vibration reduces the frictional resistance between the particles and the screen.

2. Decompose aggregated or agglomerated powder to prevent mesh clogging.

3. When the fine powder is damped or rubbed to generate static electricity, it will cause some materials in the troupe to agglomerate when damped or rubbed to generate static electricity. Under the action of ultrasonic waves, these agglomerates can be crushed for a second time, thereby increasing the output.

Sieve spore powder

Sieve 500 mesh bismuth tungstate

Sieve Graphite Powder

Ultrasonic Sieve Shake can be used for sieving and filtering of fine powder within 500 mesh, widely used in abrasives, chemical industry, metallurgy, pharmacopoeia, metallurgy, chemical industry, medicine, powder, building materials, national scientific research, production and laboratories, national defense, geology, etc. Departments, colleges and universities quality inspection room, laboratory, the specific materials are flour, medicine powder, coal slime, diamond, graphite, abrasive, plastic powder, calcium carbonate, spore powder, bismuth tungstate, alloy powder, grain, etc.

Calcium Hydroxide Detection

Mesh: 200 mesh, 300 mesh, 400, 500 mesh

Recommended: Diameter 200mm

Sieve Alloy Powder

Mesh: 500 mesh 300 mesh

Recommended: Diameter 300mm

Sifted Fine Flour

Yield: 600g

Recommended: Diameter 100mm

Detecting food

Mesh: 0.025mm-3mm

Recommended: Diameter 200mm

sieve seasoning

Mesh: 30, 40, 60 mesh

Recommended: Diameter 75mm

Solve the problem of network blocking: install an ultrasonic screening system to easily solve the problem of network blocking caused by agglomeration, static electricity, strong adsorption, viscosity, etc. of materials.

Accurate detection: The ultrasonic test sieve frame is made of stainless steel stretched and polished, and can be screened to 0.025-3mm.

0-99 minute timing: The detection time of the ultrasonic test sieve is controlled by a time relay, which can accurately control the inspection time and automatically shut down at a fixed time.

Multi-layer screen frame: 1-6 layers of screen frame are optional, and the material can be screened into 2-7 particle segments.

When Ultrasonic Sieve Shake is working, the high-frequency electrical oscillation generated by the ultrasonic vibration power supply is evenly transmitted to the screen surface by the oscillator, and the materials on the screen are superimposed with ultrasonic vibration while doing low-frequency three-dimensional vibration, which can prevent the mesh from clogging , but also to improve screening yield and quality.

| serial number | name | unit | parameter |

| 01 | sieve frame | layer | 1~5 |

| 02 | screen frame diameter | mm | 300,200,100 |

| 03 | sieve particle size | mm | 0.025~3 |

| 04 | noise | dB | less than 50 |

| 05 | amplitude | mm | 0~3 |

| 06 | vibration frequency | times/min | 1400 |

| 07 | external dimensions | length*width*height | 350:350:300+N*50 |

| 08 | power supply | V;HZ | 220;50 |

| 09 | machine weight | Kg | 36 |

A: Standard test sieve (main machine)—DH-300 test sieve is a particle size analysis instrument that can automatically shut down at regular intervals to ensure test repeatability, comprehensive functions and easy operation. A granular material can be precisely divided into 2~8 particle segments at the same time. It can be used to analyze the fineness and impurity content of slurry materials.

B: Ultrasonic vibration power supply - built-in microcomputer chip, which can automatically track the whole digital frequency according to the different states of the ultrasonic wave.

C: T200 type test screen frame - an ultrasonic oscillator is installed on the national standard Φ 200 screen frame.

D: High-frequency connection line—the T200 test screen frame and the ultrasonic vibration power supply are connected by cables.

E: Connector - aviation connection plug-in.

F: Oscillator - high-performance ultrasonic conversion device.

Compared with the standard test sieve, the frequency band output by the Ultrasonic Sieve Shaker CNC power supply is transmitted to the screen surface 360,000 times/min through the transducer, so it is not suitable for strong adsorption, easy agglomeration, high static electricity, high precision, high density, light specific gravity, etc. Materials that are difficult to be screened have better results, the screening accuracy can be increased by 1-70%, and the output can be increased by 0.5-10 times.

1. Adjust the screening time according to the needs of screening. There is a time relay on the host panel that can be accurate to seconds, and the timing can be adjusted within 0-99 minutes and 59 seconds.

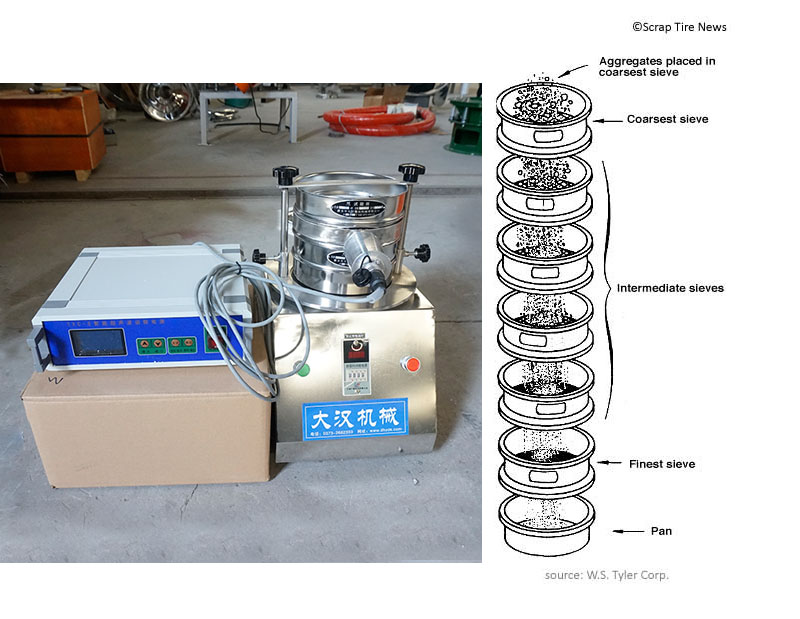

2. The principle of the screen frame from top to bottom is from coarse to fine to prevent the screen frame. At most 8 screen frames can be placed, and the materials that need to be screened are placed on the upper layer.

3. Put the screen frame on the main unit, and lock the nuts on the top and both sides. The specific method is: first loosen the Ultrasonic Sieve Shaker and the four locking nuts on both sides, so that the two uprights on both sides can fall freely on the standard test sieve that has been placed, and then lock the two sides. Lock the nuts, and finally lock the two nuts on the top of the screen machine. Note that the nuts on the top and both sides must be tightened.

4. After the screen frame is placed, it can be turned on and used. Press the green button on the host and turn on the ultrasonic system to set the screening time, which can automatically control the screening of materials. If you need to pause in the middle, you can directly press the red button. One-click to end sieving.

Dahan Ultrasonic Sieve Shake manufacturer specializes in selling Ultrasonic Sieve Shake (ultrasonic standard Sieve Shake), stainless steel Ultrasonic Sieve Shake, ultrasonic test sieve, ultrasonic test sieve, ultrasonic laboratory vibrating sieve, chemical dye ultrasonic test sieve and other equipment, the price is as low as $50 , Ultrasonic Sieve Shake is a special equipment for fine powder detection and sieving within 500 meshes. It has high detection accuracy and no clogging of the sieve. The sieve frame is available in 200mm and 300mm.

Laboratory Sieve Shaker Machine

Measuring range: 20µm-125mm

Price: $600.00 - $980.00/Set

Screening particle size: 0.025-3mm

Price: $538.00 - $925.00/Set

Screening particle size: 0.025-3mm

Price: $650.00 - $800.00/Set

Screening particle size: 0.025-3mm

Price: $650.00 - $800.00/Set

Introduction and Technical Parameters of Ultrasonic Sieve Shake

Ultrasonic Sieve Shake is the connection of test sieve, ultrasonic power supply, ultrasonic transducer, etc., which can screen 325 mesh, 500 mesh, 600 mesh or even finer materials. ...

Ultrasonic Sieve Shake Price: $350.00-$1,500.00 Ultrasonic Sieve Shake can be widely used in laboratories in pharmaceutical, metallurgy, chemical industry, mineral processing, food ...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap