![[field:title/]](/uploads/allimg/250110/2-250110105S3192-lp.png)

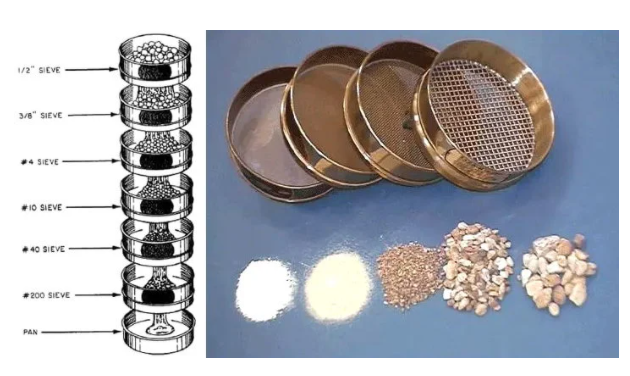

Test sieve particle size test is a commonly used particle size test method, which separates and measures the particle size distribution of particles by using sieves with different sizes of mesh.

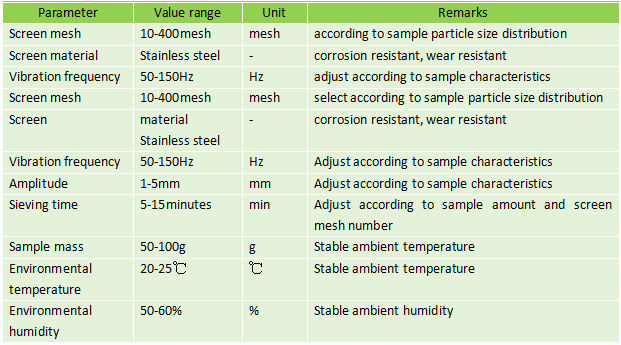

Screen size: 80 mesh in general

Vibration parameters: vibration frequency is 60 Hz, amplitude is 3 mm.

Test time: The test screen vibration screening time is about 15 minutes.

Material: stainless steel screen and stainless steel screen body, with corrosion resistance and wear resistance.

Scope of application: suitable for laboratory particle screening tests and particle material analysis in small-scale production, suitable for particle material screening and particle size analysis in the fields of grain, chemical, pharmaceutical, food, etc.

Use: used for particle size analysis and screening tests of particle materials, to help evaluate the particle size characteristics and distribution of particle materials.

Test Sieve Particle Size Test is a test method that obtains the particle size distribution by screening particulate matter through a series of sieves with different apertures. It is widely used in industrial production, scientific research experiments and other fields to control product quality, study material properties, etc.

Test sieve particle size test is based on the physical properties of particles, that is, whether the particles can pass through a sieve hole of a specific size. During the test, the particles to be tested are placed on the sieve, and the sieve is vibrated or shaken to separate the particles according to size through the sieve holes. By measuring the particles remaining on the sieve surfaceand the particles passing through the sieve holes, the particle size distribution of the particles can be calculated.

Screening method: Screening method is divided into two forms: dry screening and wet screening. Dry screening is suitable for particles that are not easy to agglomerate or absorb moisture; wet screening is suitable for particles that are easy to agglomerate or absorb moisture. The particles are prevented from agglomerating by adding an appropriate amount of liquid during the screening process. Screening can be done manually or using equipment such as vibrating screens, negative pressure screens, and fully automatic screens.

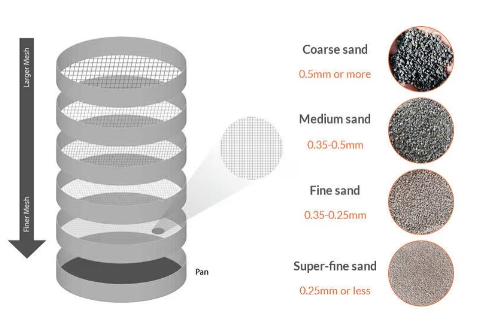

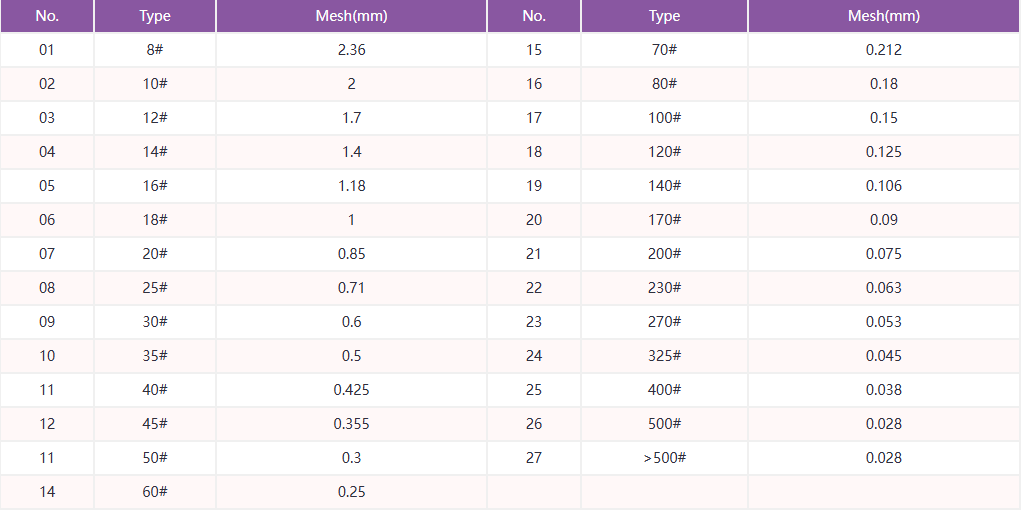

Screening steps: According to the particle size and distribution range of the sample to be tested, a set of sieves with different mesh sizes are selected and stacked together, with the larger mesh size on top and the smaller mesh size on the bottom. Place the sample to be tested in the top sieve and then install the lid. The entire set of test sieves is firmly mounted on the vibrating screen machine and screened with the help of the vibration of the vibrating screen machine. After the screening is completed, remove each sieve, carefully weigh and record the sieve residue on each sieve.

1. Intuitiveness: The sieving method can intuitively display the particle size distribution of the particles. Through the proportional relationship between the sieve residue and the sieve excess, the size distribution of the particles can be intuitively understood.

2. Wide applicability: The sieving method is applicable to various types of particles, including metal powder, non-metallic powder, ceramic powder, etc.

3. Accuracy: The accuracy of the sieving method depends on the accuracy of the sieve and the control of the sieving process. Therefore, during the test process, factors such as sieving time and sieving intensity need to be strictly controlled to ensure the accuracy of the test results.

Test sieve particle size test is widely used in powder industry, material science, geological exploration, environmental monitoring and other fields. By testing the particle size distribution of particles, we can understand the information about the physical and chemical properties, processing performance and application fields of particles, and provide important basis for product quality control and process optimization.

Powder industry: Test sieve particle size test is used to determine the particle size distribution of powders, granules and bulk materials.

Material science: Particle size testing is key to evaluating the quality, performance and application potential of materials.

Geological exploration: Geologists use test sieve particle size test to analyze the particle size composition of soil, rocks and sediments.

Environmental monitoring: Particle size test is used to evaluate particulate pollution in air, water and soil.

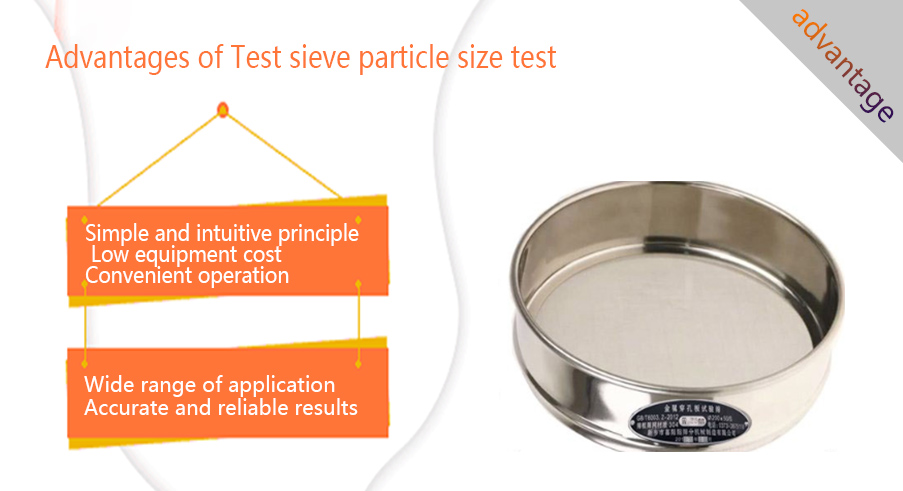

1. Simple and intuitive principle: By observing whether the particles can pass through the sieve holes of a specific size, the particle size distribution of the particles can be intuitively understood.

2. Low equipment cost: Compared with other particle size test methods, the equipment required for the test sieve particle size test is relatively simple and low in cost.

3. Convenient operation: The operating steps of the test sieve particle size test are relatively simple and do not require complex pretreatment or instrument settings. The test results can be obtained through simple observation and calculation, which is easy to implement and repeat.

4. Wide range of application: The test sieve particle size test is suitable for various types of particles. At the same time, this method is also suitable for particles with different particle size ranges, from micron to millimeter level.

5. Accurate and reliable results: When the test conditions are strictly controlled, the results of the test sieve particle size test have high accuracy and reliability.

Sieve selection: The appropriate sieve should be selected according to the particle size and distribution range of the particles to be tested. The aperture of the sieve should cover the particle size range of the particles to be tested to ensure the comprehensiveness of the test.

Control of the sieving process: The appropriate vibration frequency and sieving time should be controlled during the sieving process to ensure that the particles can be fully separated. At the same time, attention should be paid to prevent the loss and flying of particles during the sieving process.

Data processing: After the test, the collected data should be processed and analyzed. By calculating the proportional relationship between the sieve residue and the sieve excess, information such as the particle size distribution curve and the cumulative distribution curve of the particles can be obtained.

Juice 20cm test sieve is a screening tool specially used in juice production and related research fields. It usually has specific size specifications, the diameter or side length of...

20cm test sieve for garden soil

20cm test sieve for garden soil is used in horticultural soil management to analyze particle size distribution to determine soil type, texture, and fertility and to screen out impur...

Chinese herbal medicine vibrating screen

Chinese herbal medicine vibrating screen is a piece of equipment specially used for screening Chinese medicinal materials. ......

Laboratory test sieve is commonly used sieving tools in laboratories and is used for particle size analysis and classification of granular materials. Laboratory test sieve usually c...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap