Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different sizes pass through the sieve, the smaller particles pass through the holes of the sieve, and the larger particles are retained by the sieve. It can be used for particle size structure detection of granular and powdery materials, screening and filtration of liquid solid content and sundries.

Price: $15.00-$480.00/Set Chat Now

Mesh: 2-500 mesh

Mesh precision: 0.025-3mm

Screen frame diameter: 400mm, 300mm, 200mm, 100mm, 75mm

Screen frame: 1~8 layers

1. Made of sturdy and durable materials with high strength and wear resistance.

2. The test analysis sieve can finely screen particulate matter, down to the micron level.

3. Through advanced screening technology and strict quality control, human errors and equipment own errors are reduced.

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

Test Analysis Sieve is a sieve used to determine the size distribution of material particles and separate mixtures. It is mainly used to make mixtures of particles of different sizes pass through the sieve. It is suitable for screening in various industries and testing departments. It is used in chemical industry, geological exploration, powder particles. , Building materials, laboratories, medicines, etc. for particle size analysis, filtration and testing, and play the role of screening, filtering and grading.

Classification by material: Stainless steel sieve is the most commonly used material, with the advantages of corrosion resistance, high temperature resistance, high strength, etc., suitable for screening of various materials. Copper sieve has good thermal conductivity and is often used for high temperature screening, but it is easy to oxidize. Nylon sieve has good wear resistance and is suitable for screening of fine particles, but its temperature resistance is poor.

Classification by hole type: round hole test analysis sieve is the most common hole type, with uniform hole diameter and good screening effect. The hole type of square hole test analysis sieve is regular, suitable for screening with special requirements for particle shape. The rectangular hole test analysis sieve is suitable for screening with special requirements for particle aspect ratio.

Classification by aperture: The aperture range of the test analysis sieve is very wide, ranging from tens of microns to several millimeters. You can choose the appropriate sieve according to the particle size range of the measured particles.

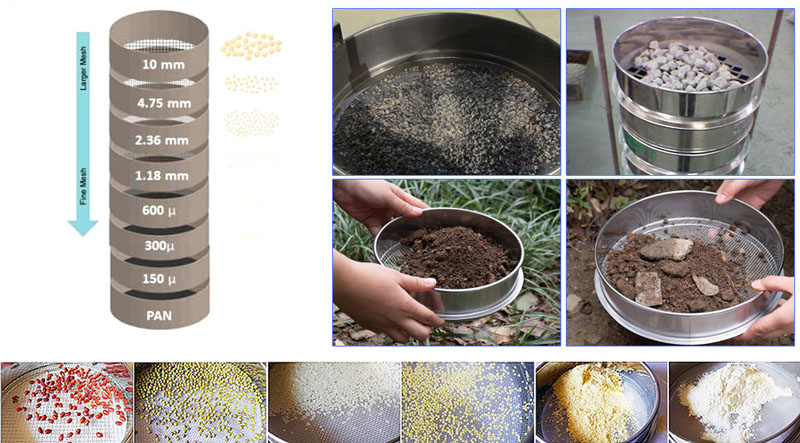

Soil Testing Analysis

Spice Testing Analysis

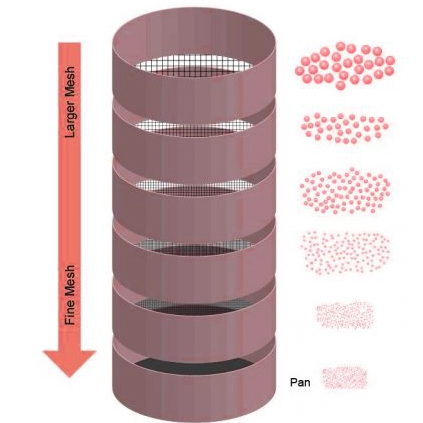

Test Analysis Sieve is used to determine the content percentage of different particle sizes in the material, so as to achieve the purpose of the analysis of different particles and the detection and analysis of particle size composition.

Particle size analysis: In materials science or geology, test analysis sieves are often used to determine the size distribution of particles, such as the particle size of soil, sand or powder.

Quality control: In industrial production, test analysis sieves can ensure that products meet specific specifications through sieving tests, such as the uniformity of drug powders in pharmaceutical production.

Impurity separation: Test analysis sieves are used to remove impurities or unwanted components from samples, such as separating debris in food processing.

Experimental research: Test analysis sieves can help researchers separate particles or molecules of a specific size for further analysis of their properties.

Test Analysis Sieve is widely used in laboratories, quality inspection rooms, chemical experiments, etc., for vibratory screening, filtering and screening for the particle size structure, liquid solid content and sundries of granular and powdery materials. Eliminate impurities to help the test to be completed smoothly.

As a precision instrument, the test analysis sieve plays an indispensable role in modern scientific research, production and quality control. It is widely used in laboratories, quality inspection rooms, chemical experiments and other fields for accurate particle size analysis, screening and filtration of granular and powdered materials. With efficient vibration screening and filtration screening mechanism, the test analysis sieve can remove impurities in the material and help scientific research and quality inspection work to be completed smoothly and smoothly.

1. Can be screened to 0.025-3mm in the inspection process

2. The inspection and screening time is controlled by the time relay, and the inspection time is accurately controlled within one second.

3. The Test Analysis Sieve machine is made of 304 stainless steel, which is suitable for the screening of corrosive acid and alkali materials and can guarantee its service life.

4. The screening equipment is a small screening equipment, so its vibration motor is small in size and will not produce large noise pollution during work.

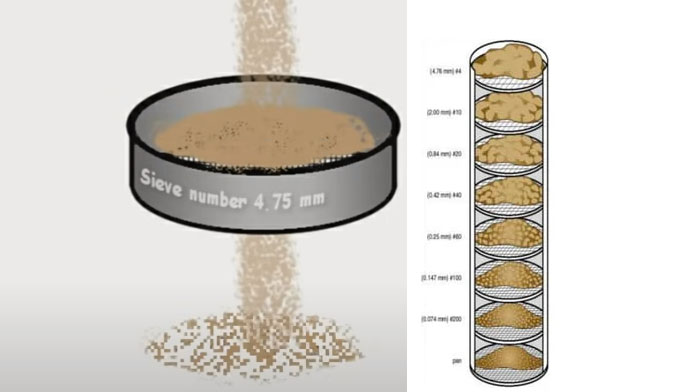

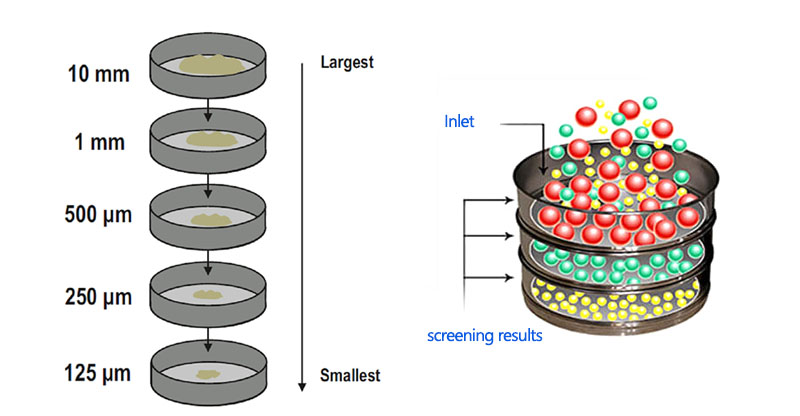

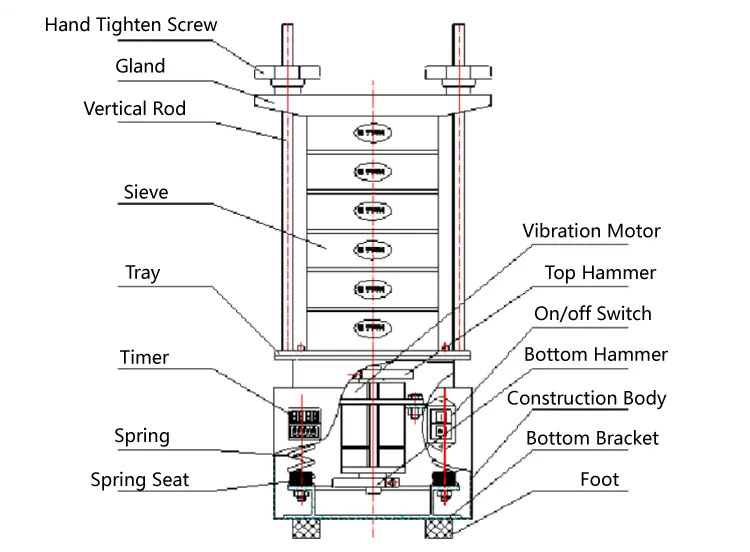

Test Analysis Sieve uses a vertical vibrating motor as the excitation source of the entire motor, drives the upper vibrating plate to vibrate through the vibrating motor, and then transmits it to the screen frame placed on the upper part of the vibrating plate through the vibrating plate, and then the screen frame that needs to detect the mesh size Sieve the material particles smaller than the aperture of the sieve to the lower sieve frame, so that only the same particle size is left in each layer of the inspection sieve, so as to achieve the separation of different particle sizes and determine the particle size composition of the material, so that the sieve The materials in the box can achieve very effective filtering, grading and screening purposes.

| mesh size | Standard mesh | mesh size | Standard mesh |

| 4.75mm | 4 mesh | 0.355mm | 45 mesh |

| 4.00mm | 5 mesh | 0.300mm | 50 mesh |

| 3.35mm | 6 mesh | 0.250mm | 60 mesh |

| 2.80mm | 7 mesh | 0.212mm | 70 mesh |

| 2.36mm | 8 mesh | 0.180mm | 80 mesh |

| 2.00mm | 10 mesh | 0.150mm | 100 mesh |

| 1.70mm | 12 mesh | 0.125mm | 120 mesh |

| 1.40mm | 14 mesh | 0.106mm | 140 mesh |

| 1.18mm | 16 mesh | 0.090mm | 170 mesh |

| 1.00mm | 18 mesh | 0.0750mm | 200 mesh |

| 0.850mm | 20 mesh | 0.0630mm | 230 mesh |

| 0.710mm | 25 mesh | 0.0530mm | 770 mesh |

| 0.600mm | 30 mesh | 0.0450mm | 325 mesh |

| 0.500mm | 35 mesh | 0.0374mm | 400 mesh |

| serial number | name | 单位 | 参数 |

| 01 | Screen frame | 层 | 1~8 |

| 02 | Screen frame diameter | mm | Φ200 |

| 03 | Screening size | mm | 0.025~3 |

| 04 | noise | dB | less than 50 |

| 05 | amplitude | mm | 0~3 |

| 06 | vibration frequency | times/min | 1440 |

| 07 | Dimensions | length width height | 350:350:300+N*50 |

| 08 | power supply | V;HZ | 220;50 |

| 09 | Total Weight | Kg | 36 |

| 10 | vibration motor | power | 0.12KW |

Test Analysis Sieve is refined from sieve mesh, sieve frame, sieve cover and sieve bottom.

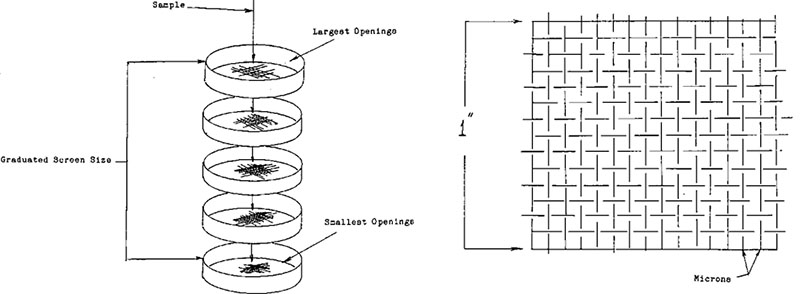

Sieve: The sieve is the most technical part of the standard sieve. Screens are mainly divided into wire woven meshes (the most widely used meshes are only square holes from 2.36 mm to 0.02 mm), punched plate screens (mainly used in large meshes, with round holes and square holes) The mesh size ranges from 0.2 to hundreds of millimeters), electroforming screen (mainly used in high-precision occasions, and each mesh can be within the average error range), the most commonly used type of screen is stainless steel braided mesh, the cost Lowest, good flexibility.

Screen Frames: Frames are round metal circles that hold the mesh in place, standard frame sizes are 3", 8" and 12". Internationally, 100mm, 200mm and 300mm are standard sizes, and the screen frame can be made of stainless steel or brass.

Screen cover: It can protect the screened material from contamination.

Bottom of the sieve: The material is stretched and formed at one time, never rusting, non-magnetic, with precise fit, no leakage of material or water.

1. Take a sample of 1000 grams.

2. Arrange the sieve set from top to bottom as 4.75 mm, 2.36 mm, 1.18 mm, 600 micron, 300 micron, 150 micron, 75 micron and Pan.

3. After the sample has been weighed, transfer the sample to a 4.75 mm sieve and close the lid.

4. Put the sieve assembly on the mechanical sieving machine and sieve for five to ten minutes.

5. Remove the assembly from the mechanical shaker and weigh the sample remaining on each sieve while recording it on the observation sheet.

Test sieve analysis is a traditional and effective method for determining the particle size distribution of a material. The particle size distribution of the particles is obtained by using a series of sieves with different apertures to grade the particles in the sample by size.

1. Sample preparation: Randomly sample the material to be tested to ensure that the sample is representative. If the sample is too large, it needs to be crushed, but be careful to avoid excessive crushing that affects the particle size distribution. The sample should be dry to avoid moisture affecting the screening results.

2. Sieve preparation: Select a suitable sieve group according to the particle size range of the sample. The sieve apertures should be arranged in order from small to large. Make sure the sieve is clean, undamaged, and the screen is tensioned.

3. Sieving process: Spread the prepared sample evenly on the top sieve. Stack the sieves on the sieving machine, start the sieving machine, and vibrate the sieve. The sieving time is determined according to the sample properties and the sieve aperture size.

Stop sieving when there is no longer a significant change in the sieve and the sieve.

5. Result analysis: Draw a particle size distribution curve. According to the calculation results, draw a particle size distribution curve to intuitively display the particle size distribution of the sample. According to the particle size distribution curve, analyze the particle size characteristics of the sample, such as average particle size, median diameter, distribution width, etc.

1. Special screen design: Test analysis sieves use specially designed screens, such as anti-clogging and anti-adhesion screens, which can reduce the clogging and adhesion of particles in screen holes.

2. Vibration technology: Test analysis sieves usually use vibrating screening machines for screening. Vibration can help particles move in the screen holes, reduce adhesion between the particles.

3. Anti-static treatment: For granular materials that are prone to electrostatic effects, screens made of anti-static materials are used to treat particles to reduce the impact of electrostatic effects.

4. Multi-layer screening: For materials with irregular particle shapes or a wide range of particle sizes, multi-layer screening methods can be used to screen in stages to improve screening accuracy.

When using a test analysis sieve, it is important to understand the characteristics of the material. For example, when the same size of aggregate is used in concrete, the concrete will not bond and the strength of the concrete will be reduced. The quality of the aggregate is judged by the size of the aggregate.

Test analysis sieve can select the right size of aggregate for the specific construction project.

For example, PCC uses 40 mm aggregates, and reinforced concrete projects use 12mm and 20mm aggregates.

Identify flakes and irregular shapes of aggregates, which are not suitable for construction projects.

Test analysis sieves produced by Dahan Machinery are mainly used for particle size analysis, impurity filtration and detection of granular and powdered materials in laboratories or quality inspection departments.

Diverse models: Test analysis sieves provide standard sieves, ultrasonic test sieves, slap sieves and other types, and support customization.

Material selection: Common materials for test analysis sieves include stainless steeland carbon steel to meet the corrosion resistance or cost requirements of different materials.

Application range: Test analysis sieves are widely used in particle size structure analysis, liquid-solid content detection and superhard material classification.

Sieve Testing(Analysis)Equipment Price

The price of Sieve Testing Equipment is $150-$2000 Sieve Testing Equipment is mainly used in various laboratories to separate and classify powders, granules, and suspensions. There...

What is the use of sieve shaker in laboratory?

Laboratory Sieve Shaker Machine is an instrument used for material particle classification, particle size detection and analysis. Particle Classification The Laboratory Sieve Shaker...

Standard sand sieve for cement testing

Cement Standard sand sieve is mainly used in various laboratories, laboratories, item screening, sieving, grading and other inspection departments to accurately determine the partic...

What is a grain sieve? Grain Sieves can screen millet, wheat, sorghum and other grains from 20m to 125mm. It can screen and grade grains. It is an instrument for analyzing the impur...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap