Tuesday March-25 2025 15:12:15

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis and quality control of corn grits (corn kernels). It is usually made of stainless steel and has the characteristics of corrosion resistance, easy cleaning, and durability. It is suitable for screening and analysis of granular materials in the food, chemical, pharmaceutical and other industries.

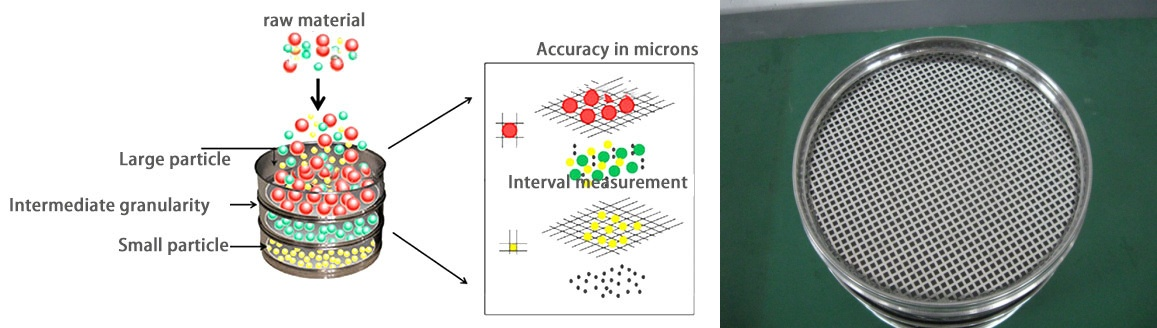

1. Particle size analysis: corn grits are graded by particle size through sieves with different apertures to determine their particle size distribution. Stainless steel corn grits test sieve is used for particle size detection in corn grits production to ensure that the product meets quality standards.

2. Quality control: The stainless steel corn grits test sieve removes oversized or undersized particles in corn grits to ensure product consistency. On the corn grits production line, it is used to monitor product quality in real time. In grain inspection, it is used to detect whether the particle size of corn grits meets the standard.

3. Impurity separation: The stainless steel corn grits test sieve removes impurities (such as stones, plant residues, etc.) in corn grits by screening. In the corn grits processing process, it is used to clean impurities in raw materials.

Stainless steel corn grits test sieve uses a stainless steel wire mesh to screen and filter the required materials. When the corn grits are placed on the sieve, the vibration of the motor forms a continuous throwing motion on the sieve. The corn grits particles smaller than the sieve aperture will fall through the sieve, while the corn grits particles larger than the sieve aperture will remain on the sieve, thereby achieving material grading and filtration.

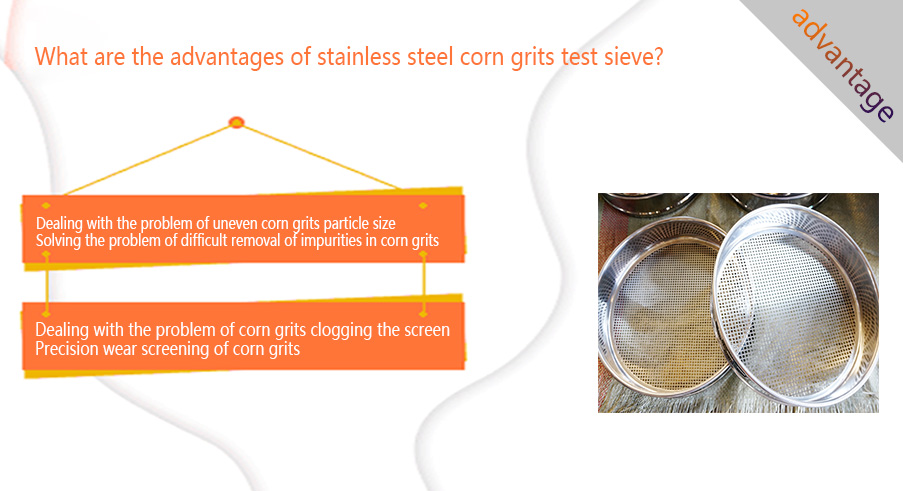

1. Dealing with the problem of uneven corn grits particle size: The stainless steel corn grits test sieve can accurately screen out corn grits that meet different particle size requirements by equipping it with screens of different mesh sizes. For coarse corn grits, use a 30-40 mesh screen; for fine corn grits, use a 60-80 mesh screen.

2. Solving the problem of difficult removal of impurities in corn grits: The stainless steel corn grits test sieve is equipped with an 8-16 mesh coarse screen, which can quickly intercept large particle impurities in corn grits. In the raw material receiving link of corn grits processing enterprises, the newly purchased corn grits may be mixed with impurities such as corn cob fragments, stones, and straw.

3. Dealing with the problem of corn grits clogging the screen: Corn grits particles (especially fine powder or wet corn grits) are easy to clog the screen, affecting the screening efficiency. Made of stainless steel, it has good anti-clogging performance. During the screening process, it is not easy to adhere to the screen, reducing the possibility of screen clogging.

4. Precision wear screening of corn grits: Stainless steel corn grits test sieves should be selected with different mesh sizes according to needs to meet different screening accuracy requirements. Calibrate the test sieve regularly to ensure the accuracy of the test. Screen according to standard operating procedures to reduce human errors.

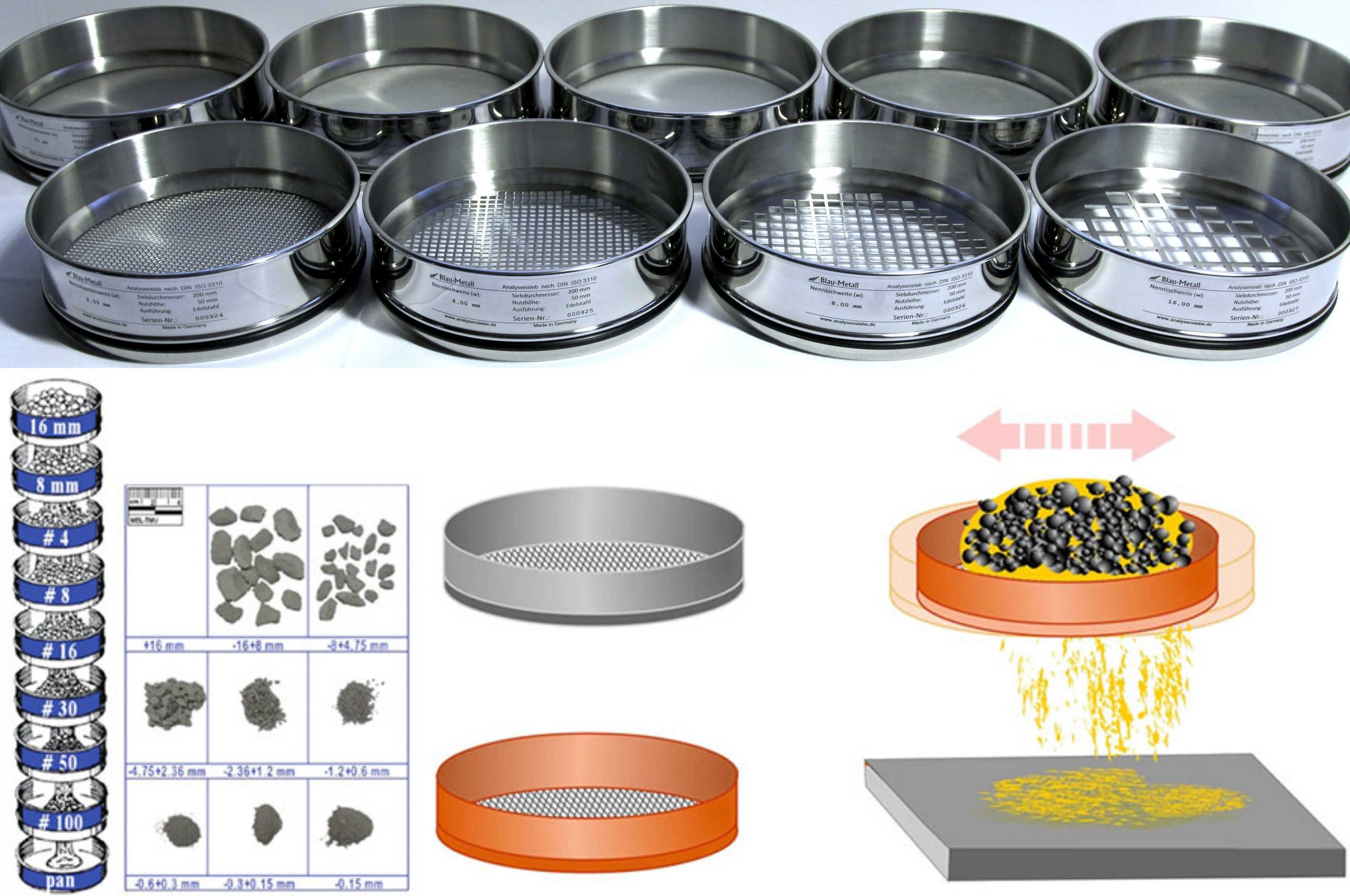

Coarse sieve: 4-8 mesh (4.75 - 2.36 mm), used to remove large particles of impurities in corn grits, suitable for preliminary screening.

Medium sieve: 10-16 mesh (2.00 - 1.18 mm), used to separate medium-sized corn grits, suitable for conventional screening in food processing.

Fine sieve: 18-30 mesh (1.00 - 0.60 mm), used to separate fine-sized corn grits, suitable for high-quality food production or special process requirements.

Ultra-fine sieve: 40-60 mesh (0.425 - 0.25 mm), used to separate ultra-fine-sized corn grits, suitable for high-precision particle size analysis or special purposes.

|

Parameter Category |

Technical Parameters |

|

Material |

Stainless steel (both screen and frame are made of stainless steel 304 or 316L) |

|

Screening mesh |

10-500 mesh (can be customized according to requirements) |

|

Sieve size |

0.025mm-2mm |

|

Frame diameter |

200mm, 300mm, 400mm (common specifications) |

|

Mesh type |

woven mesh or punched mesh |

|

Mesh fixing method |

stretch fastening or spot welding fixing |

|

Applicable standards |

ISO, ASTM, GB/T, etc |

|

Screening accuracy |

over 95% |

|

Screening method |

manual vibrating screen or used in conjunction with standard vibrating screen machine |

|

Scope of application |

screening of corn flour, flour, food, chemical, medicine and other powders |

1. Screening and grading in corn grits production process: On the corn grits production line, the stainless steel corn grits test sieve is used to accurately screen and grade corn grits. According to production requirements, the mesh aperture can be flexibly adjusted to obtain corn grits products of different particle sizes.

2. Raw material screening and pretreatment in food processing: Stainless steel corn grits test sieve is used to screen corn grits raw materials to ensure that they are suitable for the production of specific foods (such as corn flakes, corn porridge, etc.). In the deep processing of corn grits (such as corn starch and corn syrup production), it is used to pretreat raw materials to ensure that their particle size is suitable for subsequent processes.

3. Raw material grading in feed production: In feed processing plants, it is used to grade corn grits according to particle size as raw materials for different types of feed. The stainless steel corn grits test sieve provides corn grits of appropriate particle size according to animal species and growth stage, improves the digestibility and absorption rate of feed, and promotes animal growth.

4. Quality inspection in export trade: In corn grits export trade, it is used to detect whether the product meets the quality standards of the importing country.

① Preparation: Select the appropriate sieve aperture and sieve frame size according to the test requirements. Stainless steel corn grits test sieve stacks the sieves in order from large to small aperture, with the smallest aperture sieve on the bottom layer and a receiving tray at the bottom.

② Adding samples: Place the corn grits sample into the top sieve.

③ Screening: Fix the assembled test sieve on the vibrating sieving machine and start the equipment for screening.

④ Collection and analysis: After the screening is completed, remove the sieve frame layer by layer and weigh the corn grits on each layer of the sieve. Record the data and calculate the particle size distribution.

Stainless steel corn grits test sieve is an important screening tool with broad application prospects. During use and maintenance, it should be carried out in strict accordance with the operating procedures to ensure its normal operation and extend its service life.

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch production to analyze and classify fine materials...

What Is An Electromagnetic Sieve Shaker?

Electromagnetic sieve shaker is a screening equipment used for testing and laboratory research. It is often used to screen and classify small batches...

Test sieve shaker is a laboratory equipment used for particle screening and classification, also known as laboratory shaker or laboratory vibrating...

Phosphate Test Sieve is an experimental tool used to screen different particle sizes in phosphate samples and detect the phosphate...

High precision subdivision test sieve

High precision subdivision test sieve is a device used in the laboratory to perform fine particle size analysis on granular and powdery...

Mar 25, 2025

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis...

Mar 25, 2025

Laboratory Lactose Stainless Steel Test Sieve

Laboratory lactose stainless steel test sieve is a device used to accurately determine the size distr...

Mar 25, 2025

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch productio...

Mar 25, 2025

Vitamin powder slapping screen

Vitamin powder slapping screen is a device used to sieve vitamin powder. It achieves sieving through ...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap