Stainless Steel Test Sieves adopt SUS304 stainless steel screen mesh, screen frame, screen cover, screen bottom, accurate mesh, clean and hygienic, strong corrosion resistance, not easy to rust, wall thickness can reach 0.6mm, surface polishing, resistant to 400° high temperature ; Mesh can be accurate to 0.025-3 mm.

Price: $50.00-$3670.00/SetChat Now

Screening particle size: 0.025-3mm

Material: 304/316L stainless steel

Diameter of screen frame: 75mm/100mm/200mm/300mm

Application: Accurate screening, filtration and detection of particle size structure, liquid content and foreign matter content of granular and powdery materials

1. Made of high-quality stainless steel, it has acid and alkali corrosion resistance, high temperature resistance, non-magnetic properties, etc.

2. Screen hole accuracy: The screen hole size is uniform and consistent, ensuring the screening accuracy.

3. Customized service: Accept small orders, and can customize screens of different specifications according to customer needs.

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

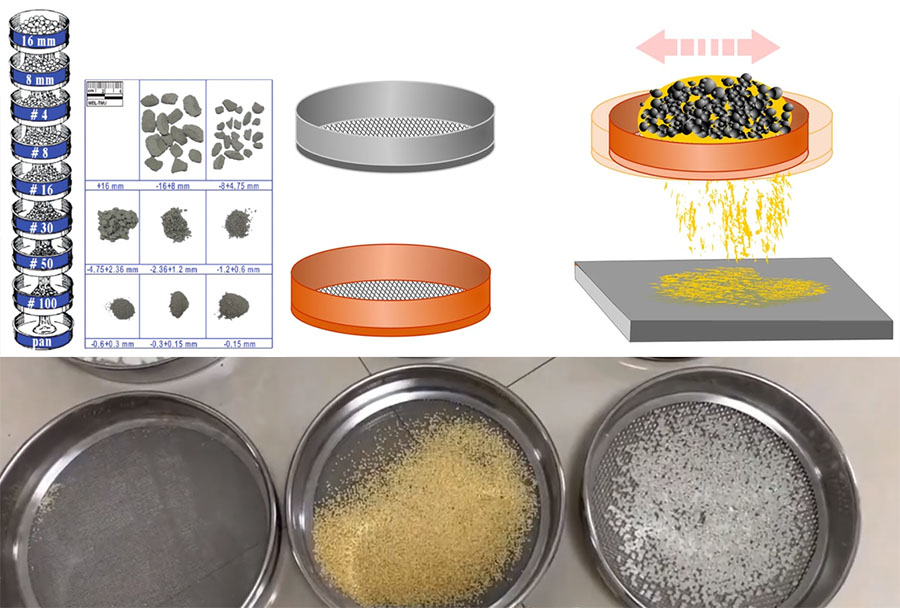

Stainless Steel Test Sieves are made of SUS304 stainless steel, with a wall thickness of 0.6mm. The surface is smooth, not easy to store materials, can withstand high temperatures of 400°, resistant to acid and alkali corrosion, not easy to rust, and non-magnetic. It is necessary to prepare granular samples. Stainless steel test sieves of different apertures. The purpose of sieving is to separate the particles that exceed the limit and continue to crush them to the specified particle size, so as to ensure that the inhomogeneous substances reach a certain degree of dispersion and reduce the reduction error in each sample preparation stage.

Separation of soybeans and soybean meal

Sieve corn flour to separate corn flour into different grades

Corn starch testing and sampling

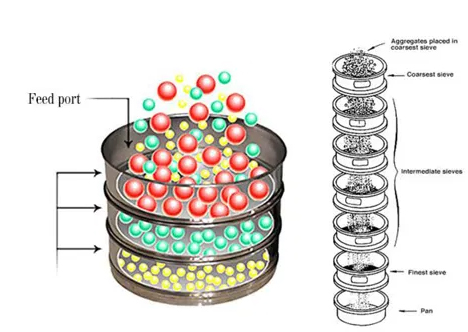

The sample to be tested is evenly spread on the top sieve. The sample particles are moved on the sieve by means of vibration or sieving machine. After screening by multiple layers of sieves, particles of different sizes are separated.

Stainless Steel Test Sieves is a tool for particle size classification and particle size detection of granule and powder materials. It can accurately separate materials and analyze particle size content composition.

Stainless Steel Test Sieves are used for particle size analysis of granular materials. Widely used in the screening and detection of granular materials in abrasives, decan, metallurgy, pharmacopoeia, chemical building materials and other industries. Specific materials include: flour, starch, corn flour, medicine powder, grain, powder, aggregate, feed, coal powder, etc.

Stainless Steel Test Sieves material has 304 stainless steel and 316L stainless steel.

304 stainless steel: resistant to high temperature of 800 ° C, with corrosion resistance, easy processing, good toughness and other characteristics. When the requirements for corrosion resistance are not high, 304 stainless steel is better because the unit price of 304 stainless steel is lower than that of 316 stainless steel.

316L stainless steel: It is a material with lower carbon content in the same series of materials. Compared with 304, 316L stainless steel has stronger chemical corrosion resistance, and is more resistant to high temperature creep, stress rupture and tensile strength than other steel grades. When the scene has higher requirements on corrosion and heat resistance, 316 stainless steel is better.

| 304 and 316L Stainless Steel Comparison | |||

| Contrast | 304 | 316L① | Remark |

| Price | Low | high | 304 stainless steel has excellent performance, low unit price, and is more widely used |

| Molybdenum content % | 0 | 2-3 | The higher the Mo content, the better the corrosion resistance and heat resistance. |

| Nickel content % | 8-10.5 | 10-14 | The higher the Ni content, the better the corrosion resistance and heat resistance. |

| Carbon content % | <0.08 | 0.03 | The higher the Carbon content, the harder the city ② the lower the Carbon content, the better the welding performance |

| Notes | ①When we refer to 316 stainless steel, we mean 316L stainless steel | ||

| ②Carbon is a strong austenite forming element, which can significantly improve the strength of steel, but the higher the carbon content in carbon steel, the worse the plasticity, and carbon also has an adverse effect on corrosion resistance | |||

1. Chemical composition difference

304 stainless steel: The main components are chromium (Cr) and nickel (Ni), which have good corrosion resistance and formability.

316 stainless steel: Molybdenum (Mo) element is added to 304 stainless steel, which greatly improves its corrosion resistance, especially the corrosion resistance to chloride ions.

2. Performance difference

| Features | 304 stainless steel | 316 stainless steel |

| Corrosion resistance | Good | Excellent, especially resistance to chloride ion corrosion |

| High temperature resistance | Good | Good |

| Strength | High | High |

| Cost | Relatively low | Relatively high |

3. Difference in application areas

304 stainless steel test sieve: Suitable for general screening work, such as screening of materials with low corrosion requirements in food, medicine, chemical and other industries.

316 stainless steel test sieve: Suitable for occasions with high corrosion resistance requirements, such as marine environment, chemical industry, and links in contact with salt in food processing.

Made of 304/316L stainless steel, wall thickness 6mm, accurate mesh, not easy to rust

Acid and alkali corrosion resistance, wear resistance, 400° high temperature resistance, easy to use, suitable for grading screening

The edging is not easy to fall off, the processing is smooth and smooth, and it is firm and durable.

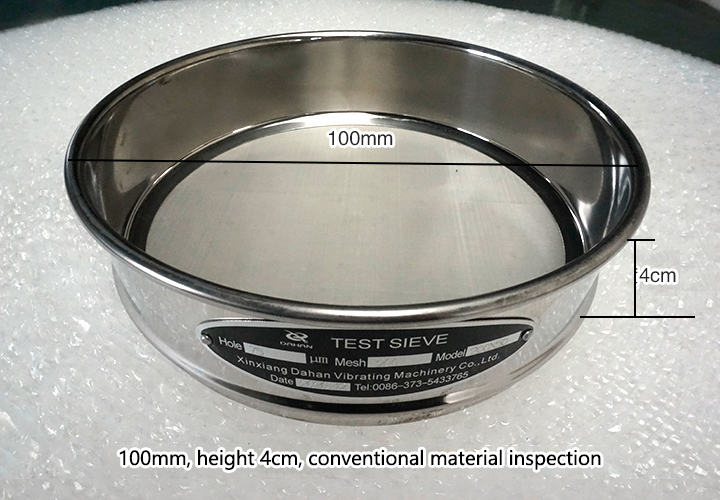

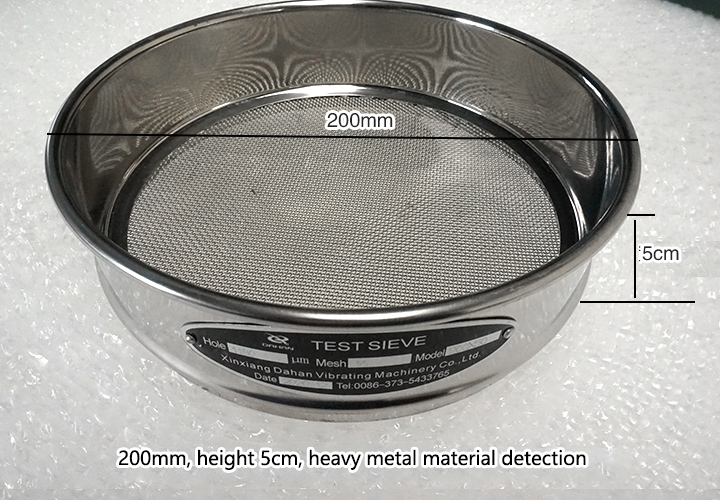

National standard SUS304/316 stainless steel 100mm sieve frame: used for conventional material detection, widely used

National standard SUS304/316 stainless steel 200mm sieve frame: used for precious metal detection

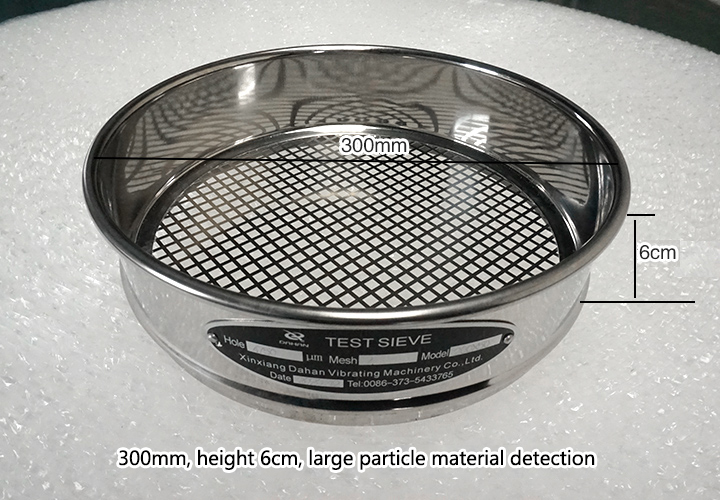

National standard SUS304/316 stainless steel 300mm sieve frame: used for large particle material detection

1. The diameter of the sieve frame is φ100mm, φ200mm, φ300mm, etc., which can be selected according to the sample volume and screening requirements.

2. The aperture size is 38μm, 45μm, 53μm, 63μm, 75μm, 80μm, 90μm, 100μm, 106μm, 125μm, 150μm, 160μm, 180μm, 200μm, 212μm, 250μm, 300μm, 315μm, 355μm, 400μm, 425μm, 500μm, 600μm, 630μm m, 710μm, 800μm, 850μm, 1.00mm, 1.18mm, 1.25mm, 1.40mm, 1.60mm, 1.70mm, 2.00mm, 2.36mm, 2.50mm, 2.80mm, 3.35mm, 4.00mm, 4.75mm

3. Screen material: 304 stainless steel, 316 stainless steel, etc., selected according to material characteristics.

4. Sieve height: 5cm-10cm

5. Filter screen fabric processing: weaving

ISO 3310: Particle size analysis - sieve analysis is a general standard for sieve analysis developed by the International Organization for Standardization, covering the specifications of sieves, sieving operations, data processing, etc.

ASTM E11: Particle size determination by sieve analysis is a standard developed by the American Society for Testing and Materials, which is basically consistent with ISO 3310, but with some minor differences.

GB/T 6003: Particle size analysis - sieve analysis is a national standard of my country, which stipulates the terminology, instruments, operation methods and result presentation of sieve analysis.

Mesh and aperture conversion formula: 1μm = 1 micrometres (micron) = 0.001 millimetre (millimeter)

The number of stainless steel test sieves is the number of holes, which is the number of holes per square inch. The larger the mesh number, the smaller the aperture. Generally speaking, mesh number * aperture (number of microns) = 15000. For example, the aperture of a 400-mesh screen is about 38 microns; the aperture of a 500-mesh screen is about 30 microns. Due to the problem of porosity, that is, because of the different thickness of the wire used in weaving the net, the standards of different countries are also different. There are currently three types of American standards, British standards and Japanese standards, of which the British and American standards are similar. , the difference is larger in Japan. Our country uses the American standard, that is, it can be calculated by the formula given above.

| Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) |

| 2 | 13 | 26 | 0.71 | 90 | 0.16 | 260 | 0.06 |

| 3 | 6.5 | 28 | 0.63 | 100 | 0.154 | 280 | 0.055 |

| 4 | 5 | 30 | 0.6 | 110 | 0.14 | 300 | 0.054 |

| 5 | 4 | 32 | 0.55 | 115 | 0.13 | 320 | 0.048 |

| 6 | 3.2 | 36 | 0.5 | 120 | 0.125 | 325 | 0.045 |

| 7 | 2.8 | 40 | 0.45 | 130 | 0.111 | 350 | 0.041 |

| 8 | 2.5 | 45 | 0.4 | 140 | 0.105 | 360 | 0.4 |

| 9 | 2.2 | 50 | 0.355 | 150 | 0.1 | 400 | 0.0385 |

| 10 | 2 | 55 | 0.315 | 160 | 0.098 | 500 | 0.03 |

| 12 | 1.6 | 60 | 0.3 | 180 | 0.09 | ||

| 14 | 1.43 | 65 | 0.25 | 190 | 0.08 | ||

| 16 | 1.25 | 70 | 0.22 | 200 | 0.075 | ||

| 18 | 1 | 75 | 0.2 | 220 | 0.07 | ||

| 20 | 0.9 | 80 | 0.18 | 240 | 0.065 | ||

| 24 | 0.8 | 85 | 0.17 | 250 | 0.063 | ||

| Stainless steel sieve specifications, if you need special specifications, you can contact online customer service consultation. | |||||||

| Parameter | Typical value | Unit | Remarks |

| Sieve frame diameter | 100mm,200mm,300mm, etc. | mm | Select according to sample quantity and screening requirements |

| Sieve mesh number | 10mesh,20mesh,40mesh, 60 mesh, 100 mesh, etc. | mesh | The larger the mesh number, the smaller the aperture |

| Sieve material | 304 stainless steel, 316 stainless steel, etc. | - | Select according to the corrosiveness of the material |

| Sieve frame material | Same as the screen material | - | Ensure consistent overall performance |

| Sieve hole shape | round, square | - | round sieve holes are more common |

| Sieve frame height | 50mm, 75mm, etc. | mm | Affects the number of screening layers |

| Vibration frequency | 50-150Hz | Hz | Affects screening efficiency |

| Amplitude | 1-5mm | mm | Affects screening effect |

| Screening time | 5-15 minutes | min | Adjust according to sample quantity and screen mesh number |

| Sample mass | 50-100g | g | Adjust according to screen frame area and sample properties |

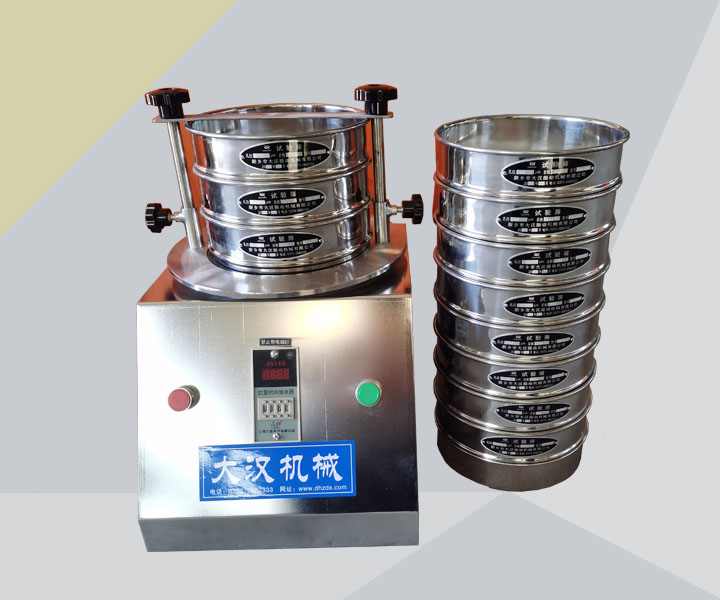

One: Adjust the time as needed. The first two digits of the time relay are minutes, and the last two digits are seconds. Adjust the reading of the time relay to the desired time.

Two: Put the stainless steel test screen frame into the equipment, tighten the nuts, and start the machine.

Three: When the running time of the test sieve is equal to the set time, the test sieve will automatically shut down, and carefully take out the sieve frame.

Screening particle size: 0.025mm-3mm

Price: $650.00 - $800.00/Set

Mesh sizes: 20µm - 40mm

Price: $523.00 - $936.00/Sets

Screening particle size: 0.025-3mm

Price: $650.00 - $800.00/Set

Stainless Steel Analysis Sieve

Mesh: 2-2800 mesh (0.003mm)

Price: $22.00 - $70.00/Set

Test Sieve Shaker is an instrument for detecting and analyzing the particle size structure and particle size distribution of 2kg of material in the test sieve. Test Sieve Shaker Pro...

How to use Stainless Steel Test Sieves?

stainless steel test sieve produced is also very strong and durable, and is often used for screening and testing in laboratories, but many users report that they will not use it....

Conversion table between classification of standard test sieve and mesh aperture

standard test sieve is mainly used in various laboratories, laboratories, research institutes, inspection rooms, etc., for random inspection, inspection and testing of small samples...

Nylon plastic for laboratory test sieves

Laboratory test sieves overview: Laboratory test sieves , also known as plastic nylon sieves, are laboratory sample separation equipment specially designed for materials that cannot...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap