![[field:title/]](/uploads/230215/1-2302150Z91N47.jpg)

Stainless Steel Analysis Sieve is made of 304 stainless steel screen mesh and screen ring through machine pressing technology. The mesh is fine, corrosion-resistant, high-temperature resistant, not easy to deform, and easy to clean.

Price: $22.00-$68.00/Set Chat Now

Sieve diameter: 75mm/100mm/200mm/300mm/400mm/500mm

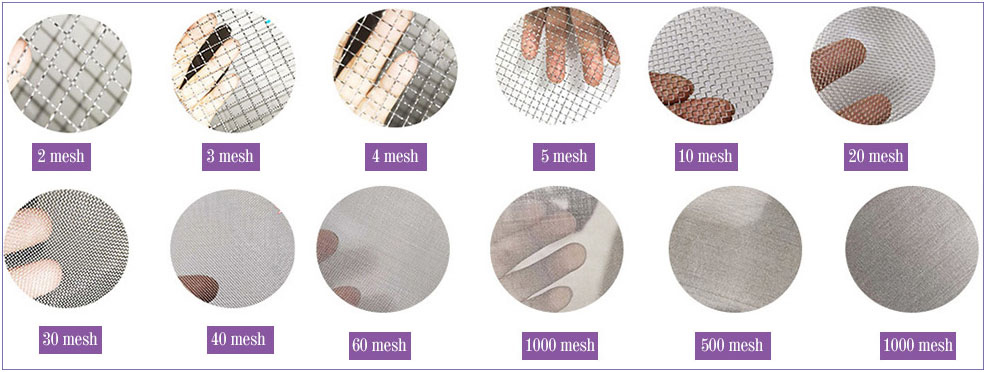

Mesh: 2-2800 mesh (0.003mm)

Material: 304 stainless steel

Features: Special for material particle size analysis and detection

Port: Any port in China (Mainland)or as you need.

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

Stainless Steel Analysis Sieve is made of 304 stainless steel screen mesh and screen ring through machine pressing technology. The bottom of the screen is made of stainless steel screen mesh with standard mesh size, fine mesh, corrosion resistance, high temperature resistance, not easy to deform, and easy to clean; it is widely used in Screening and building materials of granular materials in food, abrasive, geological prospecting, metallurgy, pharmacopoeia, chemical industry, building materials and other industries, precise screening and detection of fine particles.

Common meshes of Stainless Steel Analysis Sieve screens: 20 meshes, 30 meshes, 40 meshes, 50 meshes, 60 meshes, 80 meshes, 100 meshes, 120 meshes, etc. Special meshes can be customized. Punching nets, etc. are used to make sample sieves.

spice testing and analysis

Stainless Steel Analysis Sieve is used for the detection and analysis of particle mixtures of different sizes in laboratories in food, pharmaceutical, metallurgy, chemical, grain, abrasive and other industries.

2. Chemical industry: resins, plastics, rubber additives, dyes, fillers, etc.

3. Food: flour, cocoa, coffee, condiments, additives, etc.

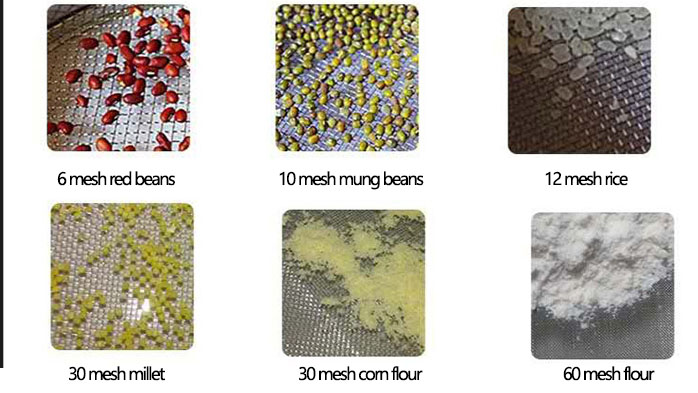

Commonly used materials are: flour, condiments, additives, cocoa powder, Chinese and Western raw materials, western medicines, grain, corn, beans, glass powder, quartz sand, wood chips, wood powder, activated carbon, resin, plastic, etc.

①Sieve soybeans with a 5-mesh sieve; ②Sieve soybeans with a 6-mesh sieve; ③Sieve mung beans with an 8-mesh sieve; ④Sieve sorghum rice with a 12-mesh sieve; ⑤Sieve rice with a 14-mesh sieve ; ⑥ 20-mesh sieve for sieving sesame; ⑦ 24-mesh sieve for sieving millet; ⑧ 30-mesh sieve for sieving corn flour; ⑨ 60-mesh sieve for sieving flour; 80~120 mesh sieve, pearl powder mostly choose 100~150 mesh sieve according to the grinding thickness.

Stainless Steel standard Analysis Sieve, detection sieve: diameter 5cm, 6cm, 8cm, 10cm, 20X5cm, 30X5cm

Stainless Steel Analysis Sieve, traditional Chinese medicine sieve, grain sieve: diameter 10X5cm, 15X5cm, 20X5cm, 25X5cm, 30X6cm, 40X7cm, 45X7cm, 50X9cm, 60X10cm

Cement Stainless Steel Analysis Sieve: 15cm, 13cm, 17X5cm, 20X5cm

Coal sample sieve, square hole, round hole: (wooden frame hole 0.2-100cm) 45X35X10cm, 75X75X10cm, 90X60X10cm

Stainless Steel Analysis Sieve material: ①Sieve bottom: stainless steel wire mesh, galvanized wire mesh, nylon wire mesh, chrome-plated sheet, stainless steel sheet, galvanized sheet, copper sheet, copper sheet, wood sheet, aluminum alloy sheet, plastic sheet. ②Sieve frame: Stainless steel plate, mild steel plate, wooden frame

Stainless Steel Analysis Sieve Bottom Shape: ①Square hole: The composition material can be: stainless steel mesh, galvanized mesh, cotton mesh, punching mesh square mesh, crimped mesh ② Round hole: The composition material can be: punching mesh round Hole net.③Rhombic hole: the composition material can be: expanded metal mesh, perforated mesh, rhombus hole mesh

1. It is made of SUS304 stainless steel, which is not easy to rust, high temperature resistance, corrosion resistance and long service life.

2. The screen is tight and the mesh is uniform.

3. The uniform diameter can be stacked and placed step by step to improve the efficiency, and it is more convenient to use the matching bottom cover for the upper and lower parts.

About the mesh number: the mesh number is the number of sieve holes in a 1-inch (25.4mm) wide screen. The larger the mesh number, the smaller the sieve through the hole. big.

| mesh | Aperture(mm) | mesh | Aperture(mm) | mesh/td> | Aperture(mm) |

| 2 mesh | 12.5 | 45 mesh | 0.4 | 220 mesh | 0.065 |

| 3 mesh | 8 | 50 mesh | 0.355 | 240 mesh | 0.063 |

| 4 mesh | 6 | 55 mesh | 0.315 | 250 mesh | 0.061 |

| 5 mesh | 6 | 60 mesh | 0.28 | 280 mesh | 0.055 |

| 6 mesh | 4 | 65 mesh | 0.25 | 300 mesh | 0.050 |

| 8 mesh | 3 | 70 mesh | 0.224 | 320 mesh | 0.045 |

| 10 mesh | 2 | 75 mesh | 0.2 | 325 mesh | 0.043 |

| 12 mesh | 1.6 | 80 mesh | 0.18 | 340 mesh | 0.041 |

| 14 mesh | 1.43 | 90 mesh | 0.16 | 360 mesh | 0.040 |

| 16 mesh | 1.25 | 100 mesh | 0.154 | 400 mesh | 0.0385 |

| 18 mesh | 1 | 110 mesh | 0.15 | 500 mesh | 0.0308 |

| 20 mesh | 0.9 | 120 mesh | 0.125 | 600 mesh | 0.026 |

| 24 mesh | 0.8 | 130 mesh | 0.112 | 800 mesh | 0.022 |

| 26 mesh | 0.71 | 140 mesh | 0.105 | 900 mesh | 0.020 |

| 28 mesh | 0.68 | 150 mesh | 0.100 | 1000 mesh | 0.015 |

| 30 mesh | 0.6 | 160 mesh | 0.096 | 1800 mesh | 0.010 |

| 32 mesh | 0.58 | 180 mesh | 0.09 | 2000 mesh | 0.008 |

| 35 mesh | 0.50 | 190 mesh | 0.08 | 2300 mesh | 0.005 |

| 40 mesh | 0.45 | 200 mesh | 0.074 | 2800 mesh | 0.003 |

1. Weigh the sample according to the regulations.

2. Sieve the sample according to the size of the sieve holes.

3. When the thickness of the sieve residue layer on each No. sieve is greater than the maximum particle size of the sample, the sieve residue on the No. sieve should be divided into two parts and sieved again until the throughput of each sieve per minute More than 0.1% of the total sample.

4. When the particle size of the sieved particles is greater than 20.0mm, it is allowed to move the particles with fingers during the sieving process.

5. Weigh the remaining weight of each sieve, accurate to 0.1% of the total weight of the sample.

6. Compared with the total amount of the sample measured before the sieve, the difference between the sum of the sieve residue and the sieve bottom residue on the Stainless Steel Analysis Sieve shall not exceed 1%.

1. Divide the sieve residue on each sieve by the total amount of the sample to calculate the percentage of the sieve residue of the sieve (accurate to 0.1%);

2. The percentage of residual sieve calculated by each sieve is added to the percentage of residual sieve of each sieve larger than the sieve number, and the cumulative percentage of residual sieve is calculated (accurate to 1%);

3. Evaluate the particle gradation of the sample according to the accumulated sieve percentage of each sieve.

Test range: 3μm-150μm

Price: $20.00 - $500.00/Set

Screening particle size: 0.025-3mm

Price: $50.00-$3670.00/Set

Mesh: 2-500 mesh

Price: $15.00-$480.00/Set

Screening particle size: 0.025-3mm

Price: $650.00 - $800.00/Set

Introduction of Stainless Steel Analysis Sieve

Stainless Steel Analysis Sieve is made of stainless steel 304; it is used for grading the particle size composition of various powder materials...

Sieve Testing(Analysis)Equipment Price

The price of Sieve Testing Equipment is $150-$2000 Sieve Testing Equipment is mainly used in various laboratories to separate and classify powders, granules, and suspensions. There...

Conversion table between classification of standard test sieve and mesh aperture

standard test sieve is mainly used in various laboratories, laboratories, research institutes, inspection rooms, etc., for random inspection, inspection and testing of small...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap