Thursday February-27 2025 10:41:02

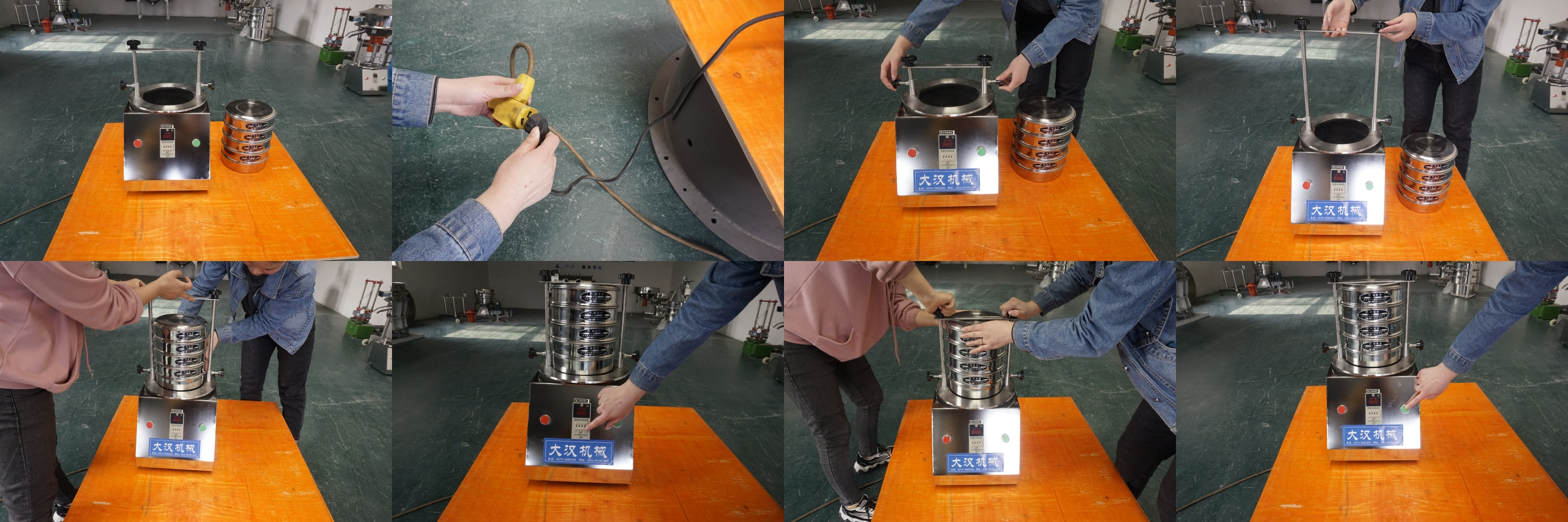

Small machine powder test sieve is a screening device used in laboratories or small production environments to perform particle size analysis on powder materials. It is small in size and easy to operate, and is suitable for screening and grading various powder materials.

Small machine powder test sieve uses the exciting force generated by the vibration motor to make the powder material on the sieve jump. Particles smaller than the sieve aperture pass through the sieve, and particles larger than the sieve aperture are retained on the sieve. By screening layer by layer, powders of different particle size ranges can be obtained, so as to analyze the particle size distribution of the powder.

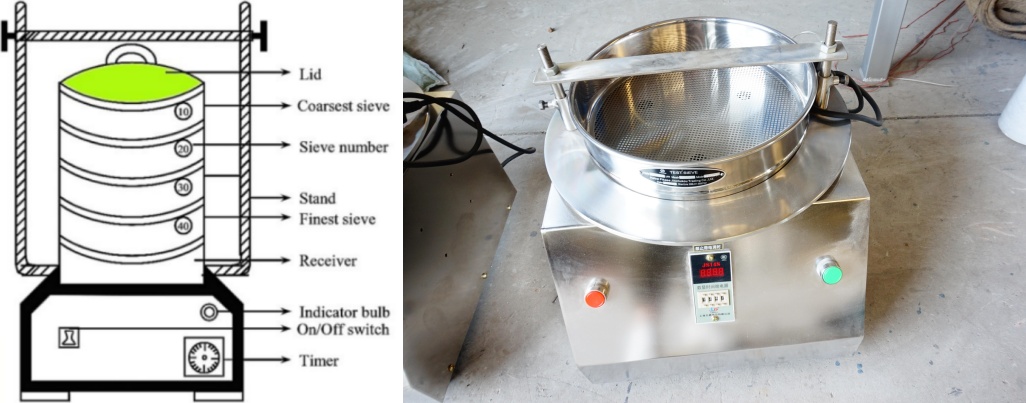

The structure of the small machine powder test sieve mainly includes the sieve frame, sieve mesh, vibration motor or rotary motor, base and spring, seal, feed port and discharge port. Its compact, modular and durable design makes it widely used in laboratories and small-scale production. Through reasonable use and maintenance, the performance advantages of the equipment can be fully utilized to meet the screening needs of different powder materials.

1. Accurate screening results: Small machine powder test sieves are equipped with efficient vibration motors or rotary motors to provide strong excitation force or rotation force, so that the powder material can be quickly dispersed and passed through the screen. Small machine powder test sieves usually have precise screens and vibration mechanisms, which can provide accurate screening results and ensure that the powder particles are classified according to the required standards.

2. Effectively solve the problem of machine powder blocking the screen: Small machine powder test sieves use vibration or rotation to quickly disperse the powder material on the screen surface, reduce the residence time of the material on the screen, and reduce the possibility of blockage. They are usually designed to handle a small amount of samples and can complete the screening process quickly and efficiently, saving time and labor costs.

3. Easy to clean and maintain: Small machine powder test sieves are usually simple in design and easy to clean and maintain. Keeping the equipment clean can ensure the accuracy of the screening results and extend the service life of the equipment. The fully enclosed design prevents dust from spilling out and ensures the health of operators and environmental safety.

4. Suitable for a variety of powder samples: Small machine powder test sieves are suitable for processing various types of powder samples and can cope with powder particles of different sizes, shapes and properties. Multiple layers of screens can be installed to achieve multi-level screening to meet the screening needs of materials of different particle sizes. For powder materials with high humidity, the screening efficiency can be improved by adjusting the vibration parameters or adding a drying device.

Laboratory research: In the laboratory, researchers use small machine powder test sieves to analyze and grade powder materials to determine their particle size distribution. Through screening, researchers can understand the particle size characteristics of powder materials and provide accurate data support for subsequent experiments.

Small-scale production: Small machine powder test sieves are used to screen raw materials to remove impurities and oversized particles. Ensure the purity and uniformity of raw materials, improve production stability and product quality. Through screening, determine whether the particle size of new raw materials meets production requirements to avoid affecting products due to excessive or too small particles.

Quality control: Small machine powder test sieves are used to detect the particle size distribution of powder materials to ensure that they meet relevant standards. Through screening, determine whether the particle size of powder materials meets the requirements to avoid affecting the quality and effect of products due to uneven particle size.

1. Material characteristics: Select the appropriate screen aperture according to the particle size range of the powder material. For materials with high humidity or high viscosity, it is necessary to select anti-blocking mesh design and easy-to-clean equipment. For materials with high hardness or strong corrosiveness, it is necessary to select screens and screen frames made of wear-resistant and corrosion-resistant materials.

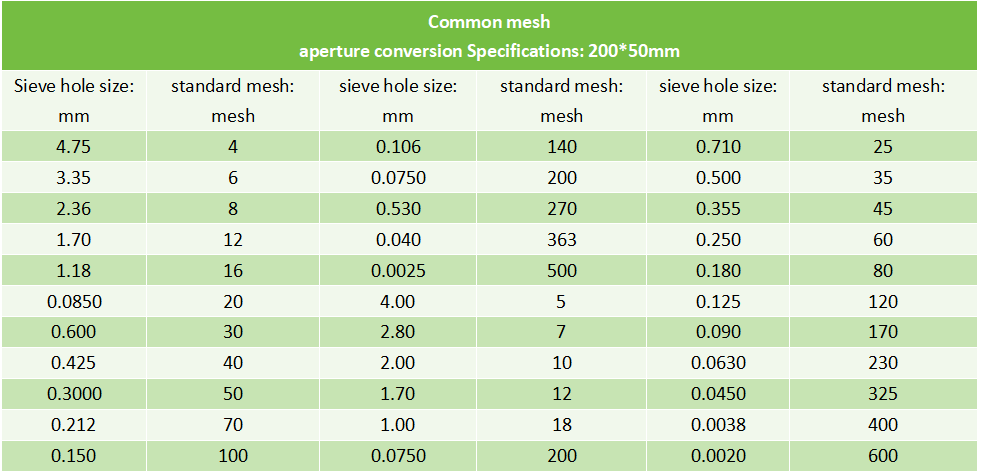

2. Screening accuracy: Select the appropriate screen mesh number (such as 100 mesh, 200 mesh, etc.) according to the screening accuracy required by the small machine powder test sieve. If multi-stage screening is required, select equipment that can install multiple layers of screens.

3. Processing capacity: Select a sieve machine of appropriate size (such as 200mm diameter, 300mm diameter, etc.) according to the sample amount screened by the small machine powder test sieve each time. Select equipment with adjustable vibration frequency and amplitude according to the processing capacity requirements.

4. Equipment material: The stainless steel material of the small machine powder test sieve is suitable for most cases, corrosion-resistant and easy to clean. Stainless steel screens are suitable for general materials, and nylon screens are suitable for sticky materials.

The price of a small machine powder test sieve can vary depending on factors such as brand, model, quality, features, performance, and additional functionalities. Generally, the price range can be from a few hundred dollars to several thousand dollars.

Low-end models: The price of low-end small powder test sieves ranges from a few hundred yuan to thousands of yuan, which is suitable for simple screening needs of general laboratories.

Mid-end models: The price of mid-end models ranges from one thousand yuan to three thousand yuan, which is suitable for laboratories with medium requirements for screening accuracy and efficiency.

High-end models: The price of high-end models is more than three thousand yuan, and even reaches tens of thousands of dollars, which is suitable for laboratories or scientific research institutions with very high screening requirements.

Small machine powder test sieve is an efficient and precise screening equipment, which is widely used in laboratory research, small-scale production and quality control. Through reasonable selection, correct use and regular maintenance, its performance advantages can be fully utilized to meet the screening needs of different powder materials.

laboratory test sieve is also called standard sieve, test sieve, laboratory vibrating screen, sample sieve, inspection sieve, standard analysis sieve...

What Is An Electromagnetic Sieve Shaker?

Electromagnetic sieve shaker is a screening equipment used for testing and laboratory research. It is often used to screen and classify small batches...

Test sieve shaker is a laboratory equipment used for particle screening and classification, also known as laboratory shaker or laboratory vibrating...

Phosphate Test Sieve is an experimental tool used to screen different particle sizes in phosphate samples and detect the phosphate...

304 stainless steel soil test sieve

304 stainless steel soil test sieve is a professional screening equipment specially used for soil particle size analysis, particle...

Feb 27, 2025

Small machine powder test sieve

Small machine powder test sieves, utilizing vibration or rotation, provide accurate and efficient par...

Feb 27, 2025

Aluminum powder laboratory test sieve

Aluminum Powder Laboratory Test Sieve is a device used for aluminum powder particle size analysis and...

Feb 27, 2025

High precision subdivision test sieve

High precision subdivision test sieve is a device used in the laboratory to perform fine particle siz...

Feb 27, 2025

What is a ceramic powder test sieve? Ceramic powder test sieve is a screening device used to accurate...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap