Sieve shaker machine is a laboratory particle size analysis tool that can perform particle separation and particle size distribution for various materials. It can be automatically timed from 0-99 minutes to ensure the repeatability and consistency of the experiment.

$600.00/SetChat Now

Sieve diameter: 75mm, 100mm, 200mm, 300mm, 400mm, 500mm

Measuring range: 20µm-125mm

Feeding amount: ≤200g

Screen material: wire braided mesh/punching plate mesh/electroforming mesh

1. Dry and wet sieving, which can measure the particle size structure and distribution of solids and suspended solids weighing up to 2kg

2. The material of the screen frame is stainless steel, brass, nylon optional

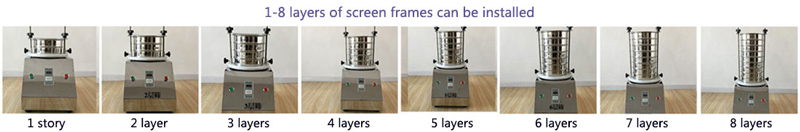

3. 1-8 layers of screen frame can be installed, which can be screened into 2-7 medium particle segments

Port:Any port in China (Mainland)or as you need.

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

The Sieve Shaker Machine is an instrument that facilitates rapid separation and particle size detection of material particles through a set of sieves. Particle size composition detection and particle size analysis can be performed on particles. It is often used in laboratories and quality inspection rooms to accurately analyze the particle size and structure of granular and powdery materials, as well as the detection and analysis of liquid and solid content. It can be screened to 0.025-3mm, the screening time is controllable, and the time is adjustable from 1s to 99h, which can ensure the repeatability and consistency of the experiment; the screen frame has 1-8 layers, and the materials can be divided into 2-7 different finenesses Specification. Materials are stainless steel and brass; models are 75mm, 100mm, 200mm, 300mm, 400mm, 500mm.

Sieve shaker machine is used for material particle separation and particle size determination. It can automatically stir particles and conduct particle separation and particle size distribution detection for various materials.

1.Particle Size Analysis: Sieve shaker machines are essential tools for determining the particle size distribution of granular materials. By passing a sample through a series of sieves with varying mesh sizes, the machine helps in analyzing the particle size distribution.

2.Quality Control: Industries such as pharmaceuticals, food processing, construction, and mining use sieve shaker machines for quality control purposes. These machines ensure that the particles meet specified size requirements for production processes.

3.Material Separation: Sieve shaker machines are used to separate materials based on particle size. They help in separating particles into different size fractions, which is crucial in various industries for processing and manufacturing purposes.

4.Research and Development: In research laboratories and academic institutions, sieve shaker machines are used for research, experimentation, and development of new materials. They play a vital role in analyzing the characteristics of different materials based on particle size.

Cement fineness test T 0502-2005 Cement fineness test method (80um sieve analysis method)

Sieve corn flour to separate corn flour into different grades

120g metal powder is sieved into 4 grades including 140 mesh, 200 mesh, 230 mesh and 325 mesh

Sieve Shaker Machine can be used for 4mm-38μm particle size detection and particle size analysis, such as: flour, starch, seasoning, cement powder, aggregate, soil, grain, alloy powder, iron powder, resin powder, plastic particles, corn flour and other materials detection and separation.

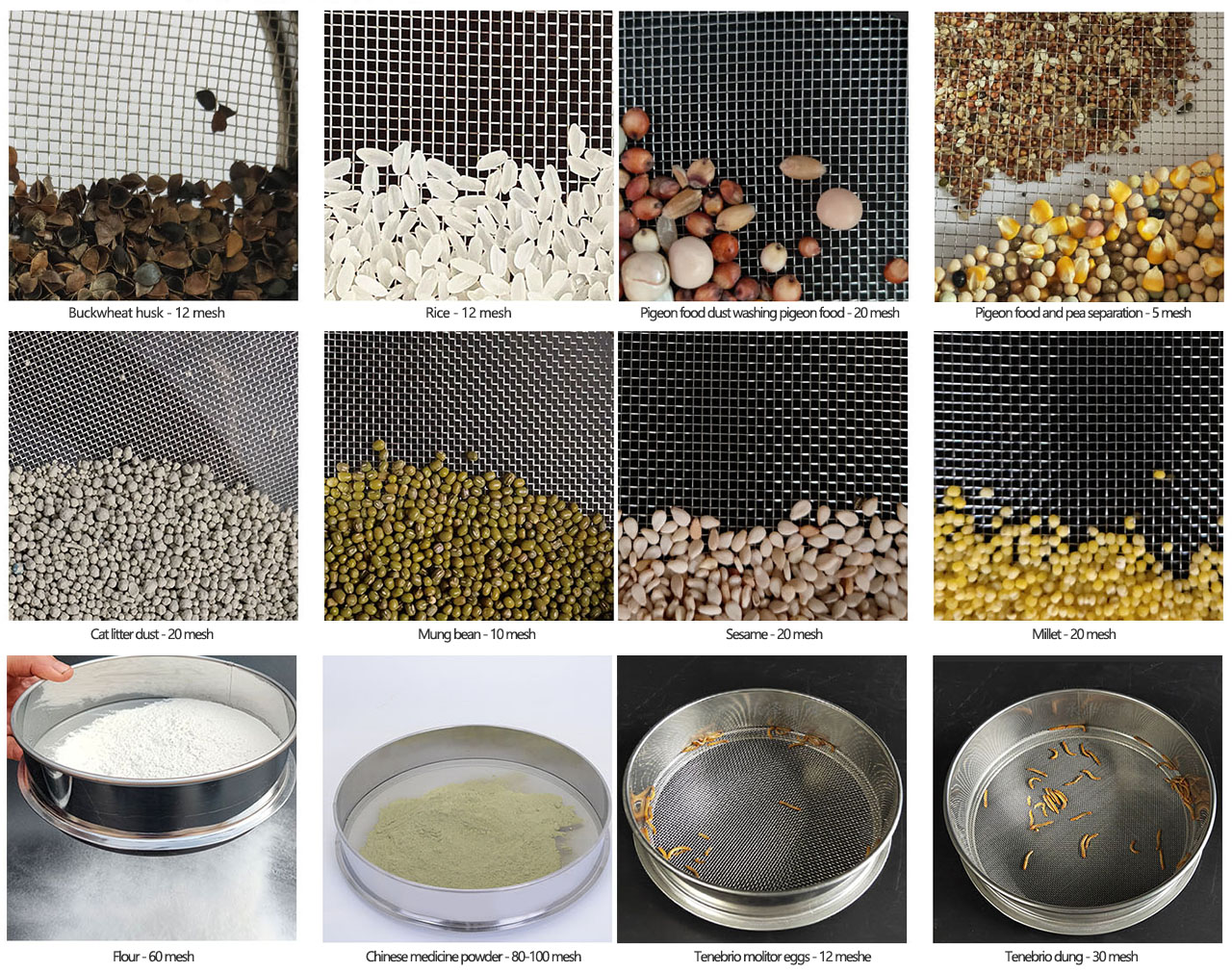

The following are the commonly used materials and mesh reference of our factory:

1. Semolina: 35 mesh, fine flour: 50 mesh

2. Coarse sesame: 10 mesh, fine sesame 20 mesh

3. Traditional Chinese medicine powder: 60 mesh - 100 mesh, Panax notoginseng powder: 80 mesh

4. Mask powder: 100 mesh or 120 mesh

5. Pearl powder: 100 mesh - 150 mesh

6. Tenebrio molitor lay eggs: 12 orders, insect excrement: 30 orders

7. Rice: 12 mesh, slender Thai basmati rice: 16 mesh

8. Soybean: 5 mesh, red bean, mung bean: 10 mesh, millet: 24 mesh

Ordinary sieve shaker machine: There are 300 and 400 types; sieve frames with diameters of 75mm, 100mm, 200mm, 300mm, 400mm, etc.; the mesh number of the sieve frame is 8-400 mesh.

Ultrasonic sieve shaker machine: The ultrasonic system is added to the ordinary sieve shaker machine to solve the problem of blocking the mesh of fine powder materials such as strong adsorption, easy clumping, high static electricity, high density and light specific gravity within 500 mesh.

Electromagnetic sieve shaker machine: Using electromagnetic vibration, the vibration frequency can reach 3000 times/min, it can sieve powder and liquid materials, the dry sieve can be sieved to 20um (635 mesh), and the new negative pressure device can dry sieve to 5um, which can solve the difficulty of drying ultra-fine powder materials. Sieve problem.

Rotap sieve shaker: It adopts reciprocating and top-strike motion, fast feeding and no mesh blocking. It is used in the production and screening of ordinary abrasives and superhard material industries. It can be equipped with 200mm and 300mm test sieves.

| Features | 200mm diameter Sieve Shaker Machine | 300mm diameter Sieve Shaker Machine |

| Processing capacity | Suitable for relatively small sample processing | Suitable for processing large samples |

| Accuracy | Suitable for situatons requiring high-precision screening | Suitable for rapid screening of large samples |

| Applications | Precise particle size analysis, screening ofsmall samplese | Rapidscreening of large batches of samples,preliminary screening of industrial samples |

Sieve shaker machine screen is divided into wire mesh, metal perforated plate screen and electroforming screen.

Wire woven mesh: produced according to GB/T6003.1-1997/ISO3310.1 standard, mesh size is 2.36mm-0.038mm, mesh material is brass, tin bronze, stainless steel, mesh frame diameter: ø 75 / 200 mm / 300 mm, the most widely used screen.

Metal perforated plate screen: produced according to the standard GB/T6003.2-1997/ISO3310.2, the size of the screen hole is 1mm-125mm, the diameter of the screen frame: ø200mm/300mm, it is a special screen for large particles and impact materials.

Electroforming screen: adopt GB/T6003.3-1999/ISO3310.3 standard, mesh size is 5μm-500μm, screen frame diameter: ø75mm/200mm, it is specially used for laboratory fine screening.

Samples up to 2 kg can be sieved dry or wet to measure quantitative particle size distributions of solids and suspensions from 20 µm - 63 mm.

1-7 layers of sieve racks can be installed, and there are many material classifications, which can accurately separate 8 particle segments of different particle sizes at the same time.

Equipped with a time relay, 0-99 minutes timing, free control of the screening time, to ensure the repeatability and consistency of the test.

The screen frame is made of SUS304 (0Cr18ni9) stainless steel by stretching and polishing, with a wall thickness of 0.6 mm, high temperature resistance below 300 °C, acid and alkali corrosion resistance, not easy to rust, and non-magnetic.

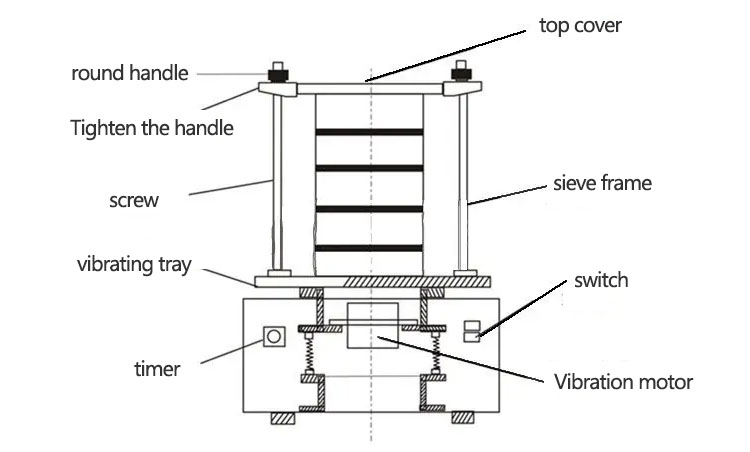

The Sieve Shaker Machine uses the vibration motor as the vibration source, and the vibration of the vibration motor drives the vibration of the base of the sieve machine, which is then transmitted to the Sieve Shaker Machine placed on the base through the base, so that the material particles smaller than the mesh surface of the test sieve are sieved into the lower test. Sieve, so that it is screened layer by layer, so that only materials with the same particle size are left in each layer of screen frame. To achieve the separation of different particle sizes and to determine the particle size composition of this material.

| Items | Name | Unit | Data |

| 1 | Layers | layer | 1-8 |

| 2 | Diameter | mm | 200, 300 |

| 3 | Sieve frame | mm | 100, 200, 300, 400 |

| 4 | Noise | db | below 50 |

| 5 | Feeding Capacity (Once) | g | <200 g/ml |

| 6 | Amplitude | mm | <5 |

| 7 | Voltage | v | 220 v / customized |

| 8 | Power | kw | 0.125 |

| 9 | Overall Dimension | mm | 450*410*700 |

| 10 | Weight | kg | 60 |

Mesh, which is the number of holes, is the number of holes per square inch. 50 mesh means that there are 50 holes per square inch, and 500 mesh is 500 holes. The larger the mesh number, the finer the particle size of the material and the smaller the aperture; The sieving particle size is the number of meshes that the particles can pass through the screen. Generally speaking, mesh number * aperture (number of microns) = 15000. For example, the aperture of a 400-mesh screen is about 38 microns; the aperture of a 500-mesh screen is about 30 microns.

| Mesh number (mesh) |

Aperture | Mesh number (mesh) |

Aperture | Mesh number (mesh) |

Aperture | Mesh number (mesh) |

Aperture |

| 5 | 4mm | 40 | 0.45mm | 180 | 88μm | 325 | 34μm |

| 6 | 3.2mm | 50 | 0.355mm | 190 | 80μm | 360 | 40μm |

| 8 | 2.5mm | 60 | 0.3mm | 200 | 76μm | 400 | 38.5μm |

| 10 | 2mm | 70 | 0.25mm | 220 | 70μm | 500 | 30.8μm |

| 12 | 1.6mm | 80 | 0.2mm | 240 | 65μm | 600 | 25μm |

| 14 | 1.43mm | 100 | 0.15mm | 250 | 63μm | 800 | 15μm |

| 16 | 1.25mm | 120 | 0.125mm | 260 | 57μm | 900 | 10μm |

| 18 | 1mm | 140 | 0.105mm | 280 | 55μm | 1000 | 8μm |

| 20 | 0.9mm | 150 | 0.1mm | 300 | 50μm | 1200 | 5μm |

| 30 | 0.6mm | 160 | 97μm | 320 | 48μm | Bottom cover | Nonporous |

Sieve shaker machine is mainly composed of round handle, fixed handle, top cover, screw, screen frame, vibration tray, vibration motor, relay, switch and other parts.

Screen: The screen is the most technical part of the sieve shaker machine. The most commonly used mesh is stainless steel woven wire mesh. Opening sizes are 5 inches (125 mm) to 635 mesh (20 microns).

Screen Frame: Frames are circular metal rings that hold the mesh in place. Standard frame sizes in the U.S. are 3 inches, 8 inches, and 12 inches. Internationally, 100mm, 200mm and 300mm are the standard sieve shaker machine mesh sizes. The screen frame can be made of stainless steel or brass.

Skirt: The main function of the skirt is to allow the sieves to be stacked without tipping over.

1. What standards do you need to provide? (Example: I need a standard sieve that meets the national standard GBT6003-1997)

2. Provide mesh size and wire diameter: The sieve shaker machine can be purchased according to the aperture and mesh, and the aperture used is also different for different meshes.

3. What material to test: Before purchasing a sieve shaker machine, it is necessary to explain the screening materials. The manufacturer will recommend suitable sieve shaker machine materials and related configurations according to the characteristics of the materials to be screened by the user. All parts of the Dahan sieve shaker machine are made of high-quality SUS304 stainless steel. The sieves above 120# in the national standard are braided with copper, if you need stainless steel, please explain.

4. Square hole sieve or round hole sieve: For cylindrical particles, the passability of the square-hole sieve is better; for irregular particles, the passability of the round-hole sieve is better.

Dahan Sieve Shaker Machine Manufacturers specializes in the production of Sieve Shaker Machine, Laboratory Sieve Shaker Machine, Stainless Steel Sieve Shaker Machine, Ultrasonic Sieve Shaker Machine, Electromagnetic Sieve Shaker Machine, Maglev Sieve Shaker Machine, Laboratory Sieve Shaker and other equipment, models are 75mm, 100mm, 200mm, 300mm, 400mm, etc.; materials are stainless steel, nylon, brass and other screen frames; sieve shaker machine price is as low as $500, you can choose the appropriate model according to your needs.

1. Determine the Sieve Shaker Machine sieve to be selected according to the inspected materials and corresponding standards.

2. Stack the Sieve Shaker Machine tools on the tray seat in sequence from large to small hole diameters and from bottom to top, and position the standard sieve tools by grooves or positioning screws.

3. Put the inspected material into the standard sieve on the upper end of the Sieve Shaker Machine, (or cover the standard sieve cover), then press the standard sieve with the sieve head set on the wire column, and tighten the sieve on the wire column Nuts to compress standard sieves. (Note: Use consistent force on both sides, and then lock with locking screws.)

4. Put the timer switch in the corresponding required position, (note that you read the timer description, the time set for different settings is different) and then turn on the power switch, and the Sieve Shaker Machine will start working.

5. After the Sieve Shaker Machine stops working, unscrew the nut on the wire column, remove the sieve head, and carefully take away the standard sieve.

6. Cut off the power supply.

Sieve shaker machine prices can vary depending on several factors such as brand, model, size, capacity, features, and the supplier.

Here is a rough price range for sieve shaker machines:

Basic models: Basic sieve shaker machines without advanced features can range from $200 to $800.

Mid-range models: Mid-range sieve shaker machines with additional features and higher capacity may cost between $800 and $2000.

High-end models: High-end sieve shaker machines with advanced technology, larger capacity, and precision control can range from $2000 to $5000 or more.

Laboratory Sieve Shaker Machine

Measuring range: 20µm-125mm

Price: $600.00 - $980.00/Set

Screening particle size: 0.025-3mm

Price: $538.00 - $925.00/Set

Screening particle size: 0.025-3mm

Price: $650.00 - $800.00/Set

Screening particle size: 0.025-3mm

Price: $650.00 - $800.00/Set

Sieve shaker machine is an instrument for powder, particle, suspension separation and particle size distribution of various materials, commonly used in laboratory for particle size analysis...

Conversion table between classification of standard test sieve and mesh aperture

standard test sieve is mainly used in various laboratories, laboratories, research institutes, inspection rooms, etc., for random inspection, inspection and testing of small samples...

Nylon plastic for laboratory test sieves

Laboratory test sieves overview: Laboratory test sieves , also known as plastic nylon sieves, are laboratory sample separation equipment specially designed for materials that cannot...

Application of wet sieve test screening material

In many cases, wet sieve test sieving, despite the inconveniences that come with it, has clear advantages over dry sieving. For example, the material to be tested may have been susp...

What problems should I pay attention to when purchasing laboratory test sieves?

The introduction as follows: Laboratory test sieves of purchase notice: Tip 1: the purpose of screening: If you are purchasing for the laboratory, you must require exquisite appeara...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap