Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials, accurate screening of granular materials and particle size detection.

Screen frame direct: 75mm, 100mm, 200mm, 300mm, 400mm Chat Now

Materials: Materials: flour, cocoa, coffee, condiments, additives, traditional Chinese medicine, etc.

Test range: 3μm-150μm

Port:Any port in China (Mainland)or as you need.

Screen mesh: 0.063mm-13mm

Size range: 45 µm to inches

Material: stainless steel, nylon, plastic, etc.

1. It has high repeatability and can be tested multiple times to verify the accuracy of the results.

2. The cost of sieving analysis test is low and it is an economical and effective particle analysis method.

3. Suitable for various granular materials, with wide applicability and flexibility.

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

Sieve Analysis Test is mainly used to classify the particle size composition of various powder materials, and is widely used in scientific research and production, laboratories and quality inspection rooms in metallurgy, powder, chemical, pharmaceutical, building materials, geology, national defense and other departments. The categories are divided into: conventional standard sample sieve, chemical special sieve, soil special sieve, stone special sieve, sand special sieve, cement special sample sieve, asphalt special sieve, coal sample special sieve, metallurgical ore inspection sieve, etc.

A set of 37 Sieve Analysis Tests, including 12 wire mesh sieves, mesh size 200μm-300μm, in line with international standard ISO3310-1:1990 and national standard GB/T60031-1997 standard R40/3 series of precision electroforming sieves25 Only, the mesh size is 455μm-41μm, the allowable deviation of the mesh size is ≥139μm±3μm, ≤127μm±2μm, check the sieve frame, sieve cover and sieve bottom, which are made of stainless steel.

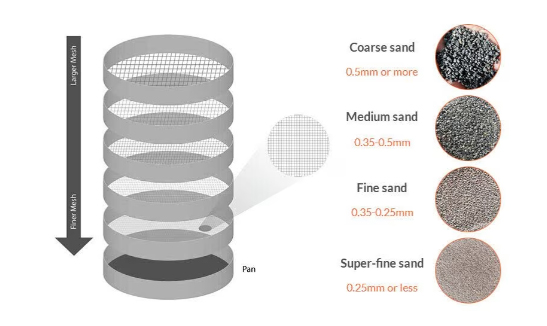

The purpose of the Sieve Analysis Test is to determine the percentage of different particle sizes in the material. Perform mechanical or sieve analysis to determine the distribution of coarser, larger size particles and use the hydrometer method to determine the distribution of finer particles.

Sieve Analysis Test-Abrasive Testing

Soil Testing Analysis

spice testing and analysis

Broad size range coverage: Able to accurately analyze particle sizes from 45 microns to inch level.

Provide percentage distribution: Provide weight or volume percentage of particles of different particle sizes.

Cost-effectiveness: Performs well in terms of cost and provides a cost-effective particle analysis solution.

Non-destructive testing: Sieve analysis testing does not cause chemical or physical changes to the material.

The Sieve Analysis Test is used in the laboratory for particle size sizing and classification of materials sampled after production.

Food industry: flour, cocoa, coffee, condiments, additives, corn, sesame, etc.

Pharmaceutical industry: Chinese and Western raw materials, Western medicine, Chinese medicine, etc.

Chemical industry: resins, plastics, rubber additives, dyes, fillers, phosphors, etc.

Metallurgical industry: lead, zinc, copper, iron, nickel, alloys, magnetic materials and other metal powders.

Abrasive industry: glass beads, alumina, corundum, chlorine carbon, emery, quartz sand, etc.

1. Aggregate performance: Through Sieve analysis test, the content of particles of different particle sizes in the aggregate can be measured to evaluate the particle size distribution of the aggregate. The results of Sieve analysis test can be used as a reference for aggregate quality and help select aggregates that meet engineering standards and construction requirements.

2. Soil classification: Sieve analysis test can quickly screen out particles of different sizes in the soil and measure their content. Through the sieving test, the distribution of particles of different particle sizes in the soil can be analyzed to evaluate the environmental quality of the soil.

3. Predict soil and water movement: The permeability of soil is closely related to its particle composition. Sieving tests provide an understanding of the soil's particle size and distribution, allowing it to assess its permeability. This is of great significance for predicting soil and water movement, preventing soil and water loss, and formulating water conservancy project plans.

Stainless steel wire mesh, galvanized wire mesh, cotton wire mesh, chrome-plated sheet, stainless steel sheet, galvanized sheet, copper sheet, plastic sheet, etc.

Sieve Analysis Test screen frame: stainless steel plate, mild steel plate, wooden frame.

Standard sieve, detection sieve: diameter 5cm, 6cm, 8cm, 10cm, 20X5cm, 30X5cm.

Sample sieve, traditional Chinese medicine sieve, grain sieve: diameter 10X5cm, 15X5cm, 20X5cm, 25X5cm, 30X6cm, 40X7cm, 45X7cm, 50X9cm, 60X10cm.

Cement screen: 15cm, 13cm, 17X5cm, 20X5cm.

The mesh types of the sample screen are: woven mesh, punched plate (round hole, square hole, long hole), electroforming, etc.

Circular sample sieve: diameter 75mm, diameter 100mm, diameter 200mm, diameter 203mm (8 inches), diameter 300mm, diameter 400mm, diameter 500mm, diameter 600mm, diameter 960mm, etc.

Square sample sieve: 500×750, 500×500, 650×450, etc.

1. Made of 304 stainless steel, wear-resistant and high-temperature resistant;

2. The screen is produced in strict accordance with the GB6003.1-1997 standard and selected by the tool microscope, and the screening is more accurate;

3. The wall thickness is 0.6 mm, and the overall molding is sturdy and durable;

4. The screen mesh and the screen frame are fixed by soldering and will not loosen.

Sieve Analysis Test uses a vertical vibration motor as the vibration source of the whole machine. The vibration motor drives the upper vibrating disc to vibrate, and then transmits it to the upper screen frame of the vibrating disc through the vibration disc. The materials with the aperture of the screen mesh are sieved to the lower sieve frame, so that only the materials of the same particle size are left in each layer of the test sieve, so as to achieve the separation of different materials and determine the particle size composition of the materials.

1. Weigh the sample according to the regulations.

2. Sieve the samples according to the size of the sieve holes.

3. When the thickness of the sieve layer on each sieve is greater than the maximum particle size value of the sample, the sieve residue on the sieve should be divided into two parts, and sieved again until the throughput of each sieve per minute is no longer. More than 0.1% of the total sample.

4. When the particle size of the sieved particles is larger than 20.0mm, during the sieving process, it is allowed to move the particles with fingers.

5. Weigh the weight of each sieve, accurate to 0.1% of the total weight of the sample.

6. Compared with the total amount of samples measured before sieving, the difference between the sum of all the sieve remainders on the sieve and the remainder at the bottom of the sieve shall not exceed 1%.

1. Divide the sieve residue on each sieve by the total amount of samples to calculate the fractional sieve residue percentage of the sieve (accurate to 0.1%);

2. The percentage of sieve residue calculated by each sieve is added to the percentage of sieve residue of each sieve larger than the sieve size, and the cumulative percentage of sieve residue is calculated (accurate to 1%);

3. According to the cumulative sieve percentage of each sieve, evaluate the particle gradation of the sample.

| Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) |

| 2 | 13 | 26 | 0.71 | 90 | 0.16 | 260 | 0.06 |

| 3 | 6.5 | 28 | 0.63 | 100 | 0.154 | 280 | 0.055 |

| 4 | 5 | 30 | 0.6 | 110 | 0.14 | 300 | 0.054 |

| 5 | 4 | 32 | 0.55 | 115 | 0.13 | 320 | 0.048 |

| 6 | 3.2 | 36 | 0.5 | 120 | 0.125 | 325 | 0.045 |

| 7 | 2.8 | 40 | 0.45 | 130 | 0.111 | 350 | 0.041 |

| 8 | 2.5 | 45 | 0.4 | 140 | 0.105 | 360 | 0.4 |

| 9 | 2.2 | 50 | 0.355 | 150 | 0.1 | 400 | 0.0385 |

| 10 | 2 | 55 | 0.315 | 160 | 0.098 | 500 | 0.03 |

| 12 | 1.6 | 60 | 0.3 | 180 | 0.09 | ||

| 14 | 1.43 | 65 | 0.25 | 190 | 0.08 | ||

| 16 | 1.25 | 70 | 0.22 | 200 | 0.075 | ||

| 18 | 1 | 75 | 0.2 | 220 | 0.07 | ||

| 20 | 0.9 | 80 | 0.18 | 240 | 0.065 | ||

| 24 | 0.8 | 85 | 0.17 | 250 | 0.063 | ||

| Stainless steel sieve specifications, if you need special specifications, you can contact online customer service consultation. | |||||||

1.Particle shape assumption: Assume that all particles are spherical. Slender or flat particles may cause errors in the results.

2.Recommendations for fine particle populations: It is recommended to use alternative particle size measurement techniques for analysis of particle populations below 45 microns.

3.Precautions for challenging materials: For materials with high hygroscopicity or electrostatic properties, you may face some challenges, such as particle agglomeration, adsorption and other abnormal phenomena, and you need to pay extra attention to deal with these situations.

In conclusion, Sieve analysis test is an important tool in various industries, providing key insights into particle size distribution. Sieve analysis test is a simple but essential procedure in materials science and civil engineering. As technology advances, the process becomes more efficient and accurate, paving the way for new applications and innovations. Accurate execution of Sieve analysis test procedures and use of appropriate Sieve analysis test equipment are critical to obtaining reliable results.

What is sieve analysis test for cement?

Sieve analysis test for cement is an essential test carried out to determine the particle size distribution of cement particles. ...

Sieve analysis test is a widely used method in geotechnical engineering for determining the grain-size distribution of fine to ...

Sieve Testing(Analysis)Equipment Price

The price of Sieve Testing Equipment is $150-$2000 Sieve Testing Equipment is mainly used in various laboratories to separate ...

What is the use of sieve shaker in laboratory?

Laboratory Sieve Shaker Machine is an instrument used for material particle classification, particle size detection and analysis. ...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap