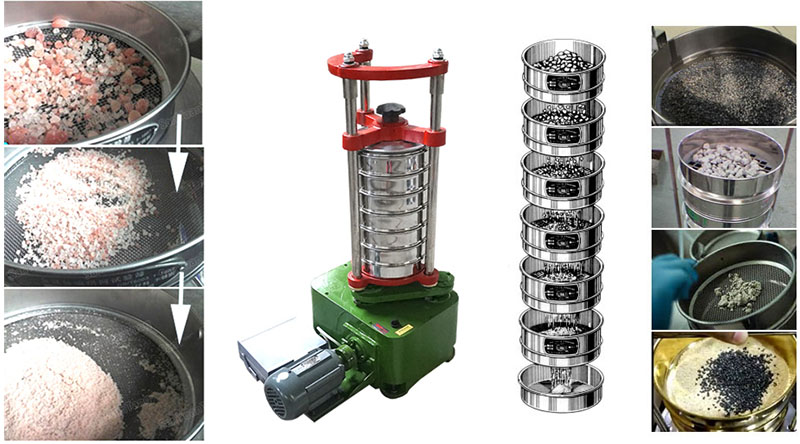

The Rotary Sieve Shaker has two motion modes of top impact and vibration, which can ensure the rapid discharge of materials without clogging the screen surface; it is equipped with a digital display time relay, which can automatically control the detection time and can be used for the separation of different material particle sizes.

Price: $500.00-$1,400.00/Set Chat Now

Number of top hits: 147 times/min

Top drop distance: 10mm

Shaking times: 221 times/min

Radius of gyration: 12.5mm

Aperture: 0-0.038mm

Available sieve layers: 7 layers

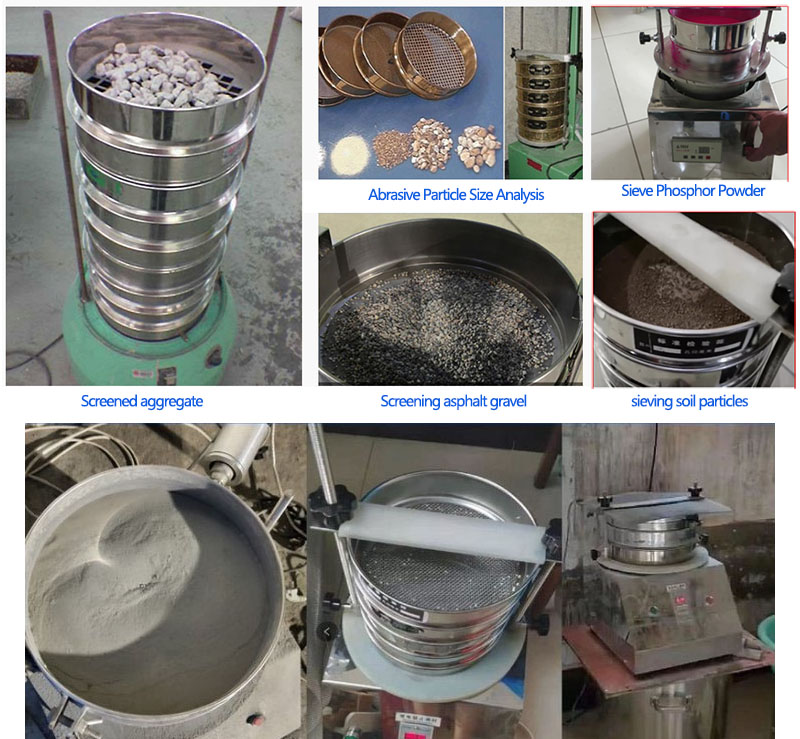

Applicable: inspection of ordinary abrasive particle size composition and production classification and particle size composition inspection of superhard materials

Features: It can effectively guarantee the sieve shaking and the number of top blows, the sieving is thorough, the feeding is fast, and it is not easy to block.

Port:Any port in China (Mainland)or as you need.

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

Rotary Sieve Shaker, also called Top Hit Sieve Shaker, utilizes the principle of eccentricity to make the platform surface of the machine vibrate and top hit regularly, replacing the advantages of manual screening. The dual motion of top hit and vibration can make the materials stuck in the mesh smooth Under the sieve, the material is discharged faster, the frequency is uniform, and the vibration sieving time can be controlled regularly; it meets the requirements of relevant test specifications for building materials, geology, transportation, and chemical industries; there are two specifications of 200mm and 300mm.

Sieve Abrasives

Sand and Gravel Sieving

Rotary Sieve Shaker is suitable for the inspection of the particle size composition of ordinary abrasives, the production classification of superhard materials and the inspection of particle size composition; it is often used in scientific research and production laboratories in geology, metallurgy, powder, chemical industry, construction cement, medicine, national defense and other industries Materials are screened and tested.

Commonly used materials: used in scientific research units, laboratories, inspection rooms, production control, etc. for aggregates, abrasives, sandstone, mortar, calcium hydroxide, coal, white lime, aluminum paste, coal water slurry, glass powder, sand, quartz Sand, steel shot, activated carbon, iron powder, fertilizer, feed, coal slime, ceramic powder, geotechnical engineering, asphalt and asphalt mixture, facing, waterproof material, cement concrete, bridge inspection, foundation pit monitoring, slurry, aluminum Inspection and analysis of powder, dry sand, tea and other materials.

1. It adopts two movement modes of top impact vibration and shaking. The material is discharged quickly without clogging. It is suitable for repeated use with high strength and high frequency.

2. It can clamp 75mm/100mm/200mm/300mm test set sieve, which is convenient and flexible for clamping and firm for clamping.

3. Equipped with an automatic stop device, it will automatically stop when the time is set.

4. The transmission method of "synchronous belt" driven by gears is selected, and the transmission is accurate and consistent; the speed ratio is accurate, and there will be no speed drop or belt slippage.

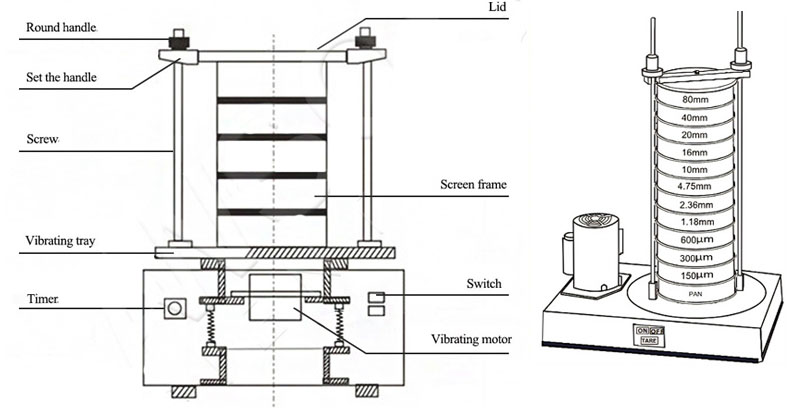

Rotary Sieve Shaker structure: motor, switch, capacitor, timer, lower box, gear shaft, double gear, swing plate, guide rod, clamping frame housing.

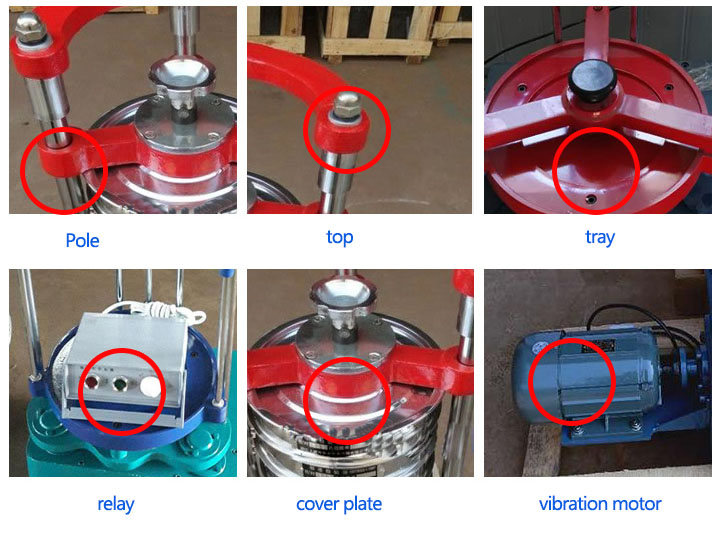

1. Slewing mechanism: The motor and pinion mounted on the upper box drive the dual gears and gears to rotate, and the main eccentric shaft rotates at the same time, causing the secondary eccentric shaft of the oscillating disk to swing with a radius of 12.5, which is driven by the support rod, etc. The sieve tray and sieve are rotated and shaken synchronously.

2. Topping mechanism: While the machine slewing mechanism is moving, the key installed on the swing plate shaft cover drives the upper camshaft to rotate; due to the speed difference between the upper protruding shaft and the lower camshaft, the upper end of the upper camshaft is effectively , hitting the sieve tray etc. for up and down movement 147 times per minute.

3. Clamping mechanism: When the sieve is installed on the machine, turn the knob clockwise, and the cone nut will move upward along the axis. ) into the knob hole and tightened to achieve the purpose of reliably fixing the sieve cover; turn the knob in the opposite direction to loosen it.

4. Appearance material: cast iron base, spray green paint, cast iron table, fixed steel rod

5. Power components: electric motor with capacitor

6. Vibration and jacking parts: eccentric wheel, spring, swing plate shaft, upper protruding shaft and lower camshaft.

1. The Rotary Sieve Shaker is driven by the motor through the transmission shaft and the worm gear to rotate the main eccentric shaft on the swing frame, which in turn drives the other two secondary eccentric shafts to rotate so that the swing of the whole sieve group has a radius, which is also equal to the plane around the eccentricity. swing.

2. At the same time, the same motor drives another pair of worm gears to pass through the cam, and the swing frame with the screen group installed on the ejector rod is periodically lifted up and dropped on the anvil of the machine base by its own weight, so that the swing frame can be shaken in a plane and circularly. Vibrate.

| model | name | unit | value |

| 01 | Sieve diameter | Cm | 20 |

| 02 | Available sieve layers | layer | 7 |

| 03 | Sieve aperture | mm | 0-0.038 |

| 04 | Number of shakes | times/min | 221 |

| 05 | Top clicks | times/min | 147 |

| 06 | Radius of gyration | mm | 12.5 |

| 07 | Top drop distance | mm | 10mm |

| 08 | Motor Power | kW | 0.38 |

| 09 | voltage | Volt | 380 |

| 10 | Motor speed | rev / min | 2800 |

| 11 | machine weight | Kilogram | 120 |

| 12 | Dimensions | mm | 586*370*952 |

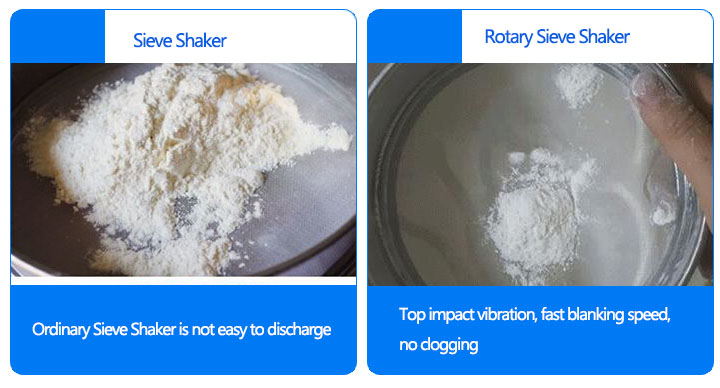

Rotary Sieve Shaker: It has two kinds of motions: jacking and reciprocating. When sieving materials, it constantly hits the screen frame to make the materials stuck on the sieve holes fall quickly, without clogging the screen, and the discharge is smoother.

Sieve Shaker: Ordinary test sieve, material screening is not easy to discharge, easy to block the screen.

1. When placing the sampling sieves, they should be stacked according to the size of the sieve holes, and a sieve chassis should be added at the same time.

2. Pour the material to be analyzed and tested into the upper sieve and cover the sieve cover, and then place it in the vibrating sieve base.

3. Rotate the lifting handle on the clamping sieve plate counterclockwise, and the ejector shaft inside clamps the support sleeve to tighten the whole set of sample sieve.

4. Turn the timer knob on the vibrating sieve machine to the time required for sieving, turn on the power switch, and the vibrating sieve machine will start to sieve and rotate.

5. There is no up and down shock when working for the first time, because the motor is reversed, please change the power cord.

6. Turn off the power after the work is over.

The Rotary Sieve Shaker plays the role of a testing instrument in the laboratory. When the Rotary Sieve Shaker sieves the material, there is a hammer on the top to continuously hit ...

Working principle of Rotary Sieve Shaker

Rotary Sieve Shaker is a small sieving machine. Its basic working principle is similar to that of ordinary vibrating sieve machines, but there are still some special features in som...

Rotary Sieve Shaker has dual motions of rotation and vibration, which can control the time of shaking sieve regularly, with reliable sieving data and convenient operation and mainte...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap