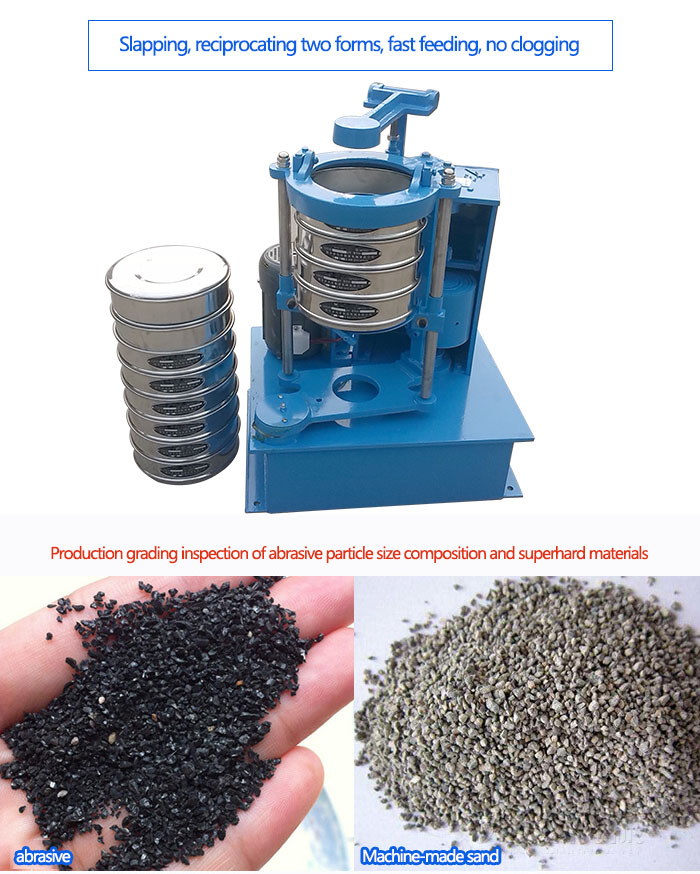

Rotap Sieve Shaker is a particle size analysis equipment widely used in laboratories and industries. It can precisely sieve powder or granular material samples into particles in different particle size ranges for analysis and control.

Price: $650.00-$1,500.00/SetChat Now

Model: 200mm/300mm

Slap times: 156±3 times/min

Slap height: 38±6mm

Rotation stroke: 25mm

Oscillation times: 290±6 times/min

Material selection: abrasive, diamond, glaze, quartz sand, soil, silica fume, polypropylene, coal

Port:Any port in China (Mainland)or as you need.

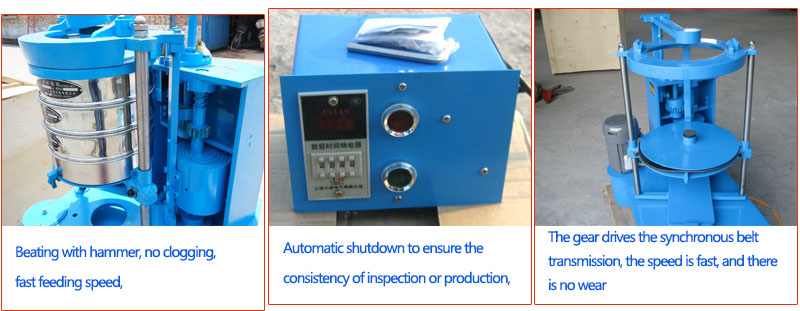

The hammer slaps the screen frame up and down, the material is cut quickly and the screening is thorough.

It can be installed with 200mm/100mm/75mm screen frame, which is convenient and flexible in clamping and firm in clamping

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

A Rotap Sieve Shaker is a type of laboratory equipment that is used to sort particles into different sizes. The machine consists of a circular frame that holds a series of stacked sieves of varying mesh sizes. The sample is placed on the top sieve, and the machine gently shakes the sieves in a circular motion, causing the particles to fall through the openings in each sieve. The shaking motion ensures that each particle is separated and sized correctly, providing an accurate measurement of the particle size distribution.

Metal powder rotap sieve shaker: The finished metal powder is 140 mesh, 200 mesh, 230 mesh, 325 mesh.

Rotap Sieve Shaker is an equipment used to detect the particle size composition of ordinary abrasives and the production classification and particle size composition detection of superhard materials. It is often used in the production and classification of diamond micropowder and superhard materials industries; specific materials include abrasives, metal powders, diamonds, Glaze, quartz sand, soil, silica fume, polypropylene, coal, cubic boron nitride, peat granules, activated carbon, silica fume, etc.

1. Pharmaceutical Industry: analyze the particle size and distribution of different drug formulations. It is used to ensure the uniformity of drugs during production and to ensure that the final product meets the quality standards.

2. Chemical Industry: used to analyze and measure the particle size and distribution of various chemicals. It is also used to ensure that the raw materials and final products meet the specified quality requirements.

3. Food Industry: Rotap Sieve Shaker is used in the food industry to analyze the particle size of different ingredients, such as flour, sugar, and various powders. It is also used to ensure that the final product has the desired texture and consistency.

4. Cement Industry: used to analyze the particle size of cement and various building materials. It is used to ensure that the materials meet the quality standards and that the final product has the desired strength and consistency.

5. Mining Industry: used in the mining industry to analyze the particle size of various ores and minerals. It is used to ensure that the materials meet the quality standards and to optimize the performance of different mineral processing operations.

| Particles: | Black beans 5 meshes, red beans 5 meshes, soybeans 6 meshes, barley 8 meshes, mung beans 10 meshes, buckwheat 12 meshes, rice 12-14 meshes, black rice 14 meshes, brown rice 14 meshes, oat kernels 14 meshes, cassia seeds 16 meshes, crushed corn 16 mesh, sesame 24 mesh, millet 24 mesh. |

| Powder type: | Fried chicken powder 10-30 mesh, corn flour 30 mesh, almond powder 30-40 mesh, whole grains 30-40 mesh, traditional Chinese medicine powder 60 mesh, thickened 40 mesh, oral 60-80 mesh, traditional Chinese medicine mask 100- 120 mesh, 50-60 mesh flour, 60 mesh rice roll, 80-100 mesh Sanqi powder, 120-150 mesh pearl powder, 80-120 mesh pine pollen, 100-120 mesh coffee powder |

| liquid type: | Filter soybean milk, honey 60-120 mesh, filter medicine residue, soup residue, tea 80-150 mesh |

| other: | Tenebrio molitor oviposition sieve 12 mesh, insect manure sieve 30 mesh, cat litter 30-40 mesh, butterfly noodle 50 mesh, pepper 6 mesh, pepper seed 8-10 mesh edible oil, mechanical oil residue 150-200 mesh. |

Single-seat Rotap sieve shaker

Structure: Single-seat Rotap sieve shaker has only one screen frame.

Features: Simple structure, easy operation, small footprint, saves laboratory space.

Scope of application: Suitable for screening of small batches of samples.

Disadvantages: Only one material can be screened at the same time, and the screening efficiency is relatively low.

Double-seat Rotap sieve shaker

Structure: Two screen frames can screen two materials at the same time.

Features: High efficiency, can process two materials at the same time; strong flexibility, different screens can be selected as needed to conduct multiple screening experiments.

Scope of application: Suitable for screening two or more materials at the same time with high requirements for screening efficiency.

Disadvantages: Relatively complex structure, large footprint, and relatively complex operation.

Sieve silicon powder

Mesh: 20-200 mesh

Recommended product: BZJ-200 Rotap Sieve Shaker

Sieve grass carbon particles

Mesh: 6mm, 8mm

Recommended product: Gear Rotap Sieve Shaker

Sieve copper powder

Mesh: 100 mesh

Recommended product: BZJ-200 Rotap Sieve Shaker

Sieve Activated Carbon

Mesh: 15-30 mesh

Recommended product: 300 Rotap Sieve Shaker

Sieve Diamond

Mesh: 30 mesh, 35 mesh, 40 mesh, 45 mesh, 50 mesh

Recommended product: BZJ-300 Rotap Sieve Shaker

High screening efficiency: It has two vibrations of reciprocating and slapping vibration at the same time, which will not block the screen surface, fast feeding and high screening accuracy

Accurate transmission: gear transmission is adopted, the speed ratio is accurate, the screening consistency is good, the gears on both sides are not in direct contact, and are not easy to wear.

Timing: It is equipped with a time relay to freely control the time, and the timing can be up to 999 seconds to ensure the repeatability and consistency of the test.

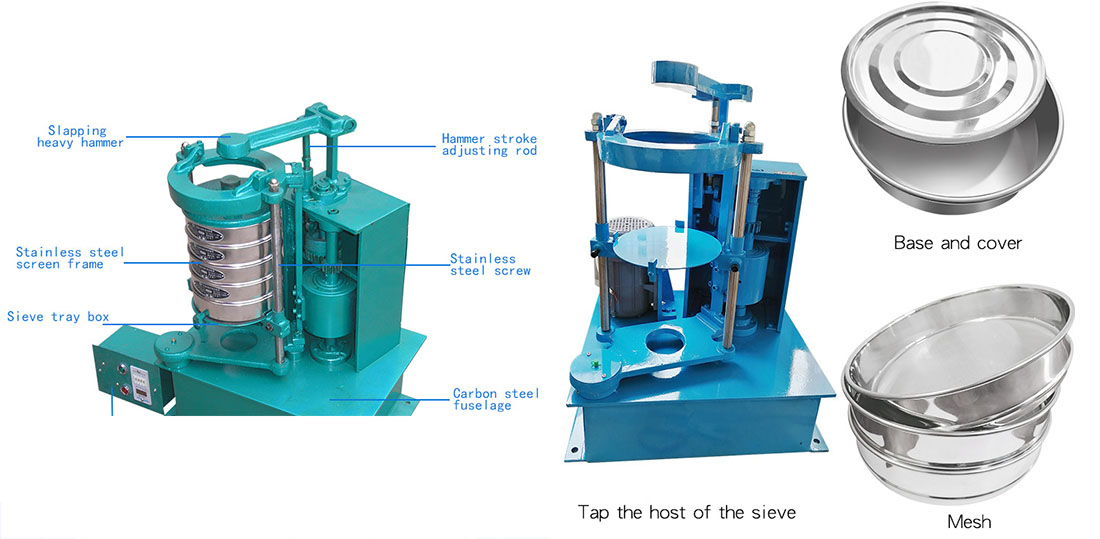

Multi-layer screening: 1-6 screen frames can be installed, and a granular material can be accurately divided into 2-7 materials of different particle sizes at the same time

The Rotap sieve shaker works by using a mechanical apparatus to generate vibrations that transfer through a set of sieves containing the sample material. The sample material is placed on the top sieve, and the Rotap shaker is switched on to generate vibration in a vertical and horizontal plane. As a result, the sample material is subjected to a series of vertical impacts, enabling the smaller particles to pass through the mesh of the sieves and collect at the bottom.

| NO | Name | Unit | Parameter |

| 1 | Sieve diameter | mm | Φ200 |

| 2 | The quantity of layer | s | 1-7 |

| 3 | Number of revolution | Timed/min | 290±6 |

| 4 | tapping | Timed/min | 1-4 |

| 5 | Tapping height | KN | 38±6 |

| 6 | Levelness of the base | mm/min | ≤0.6 |

| 7 | Motor powder | KW | 0.37 |

| 8 | Powder supply | V | 380,220 |

| 9 | Outside dimension | LWH | 433*432*785 |

| 10 | Rotation distance | mm | 25 |

| Features | Rotap Sieve Shaker | Other vibrating screens (such as circular vibrating screen, linear vibrating screen) |

| Movement mode | Vertical vibration, the screen box moves up and down | Circular motion, linear motion, etc. |

| Screening method | Material jumps on the screen surface and passes through the screen holes | Material slides or throws on the screen surface |

| Structure | The structure is relatively simple, mainly composed of screen frame, screen mesh, vibration motor, etc. | The structure is relatively complex, and may include multiple screen layers, feeding devices, etc. |

| Scope of application | Mainly used for screening and particle size analysis of small batch samples in the laboratory | Can be used for screening of large batches of materials in industrial production |

| Screening accuracy | High, suitable for fine screening | Relatively low screening accuracy |

| Noise | Relatively low | High noise |

| No. | Name | Unit | Value |

| 1 | Sieve diameter | mm | φ200, φ100, φ75 |

| 2 | Screen layer | Layer | 7 |

| 3 | 200 test screen | Set | 1 |

| 4 | Number of rotations | times/min | 290±6 |

| 5 | Number of taps | times/min | 156±3 |

| 6 | Tap height | mm | 38±6 |

| 7 | Chassis level | mm/min | ≤0.6 |

| 8 | Rotation stroke | mm | 25 |

| 9 | Motor power | kW | 0.37 |

| 10 | Motor Speed | rpm | 1400 |

| 11 | Overall dimensions | mm | Length × width × height 433×432×785 |

| 12 | Screen weight | kg | 12 |

Rotap sieve shaker is composed of gland, hammer, sieve frame, vibration motor, time relay, machine base, ejector rod, lock, etc. It is equipped with special clamps, which can clamp 75mm, 100mm, 200mm test sieves, and the clamping is convenient and flexible. The clamping is firm and can stop automatically.

1. The rotation direction of the motor must be rotated in the direction indicated by the arrow (three-phase motor) (because the cam is used to hit the ejector rod, the direction will be pinned and cannot be rotated).

The method of checking the rotation direction of the motor: lift the ejector rod before starting the machine, and then start the machine again. At this time, check the rotation direction of the motor. Make sure the direction is correct and then use it normally.

2. The equipment must be fixed before operation. It is fixed with anchor screws, and expansion screws can be used to fix the equipment on the concrete floor.

3. Install the test sieve: Loosen the fastening screws of the tray, move the tray down, load the test sieve (sample sieve, standard sieve) loaded with materials, then lift the tray to a suitable position, tighten the fastening screws, and cover the flip cover , after putting down the hammer iron, set the time to start the machine. With 100 and 75 fixtures, the corresponding size sieves can be used, and special sizes can be customized.

4. The equipment is equipped with a timing device, the user can adjust the use time, and it will automatically stop when it is turned on. The first two digits of the adjustment time are minutes, and the last two digits are seconds. Users can adjust the running time according to their needs.

5. The slap height of the equipment is adjusted before leaving the factory. If necessary, the user can also loosen the tightening nut, adjust the thread of the ejector head to raise or lower to a suitable position, and then back the nut firmly.

6. Up and down skateboards, refueling nozzles, etc. should be refueled regularly.

Dahan Rotap sieve shaker manufacturer specializes in the production of slapping sieves, slapping sieve shakers, slapping standard sieve shakers, belt slapping sieves, gear slapping sieves, can hold 200 test sieves and 75/100 sets of sieves, model There are 200 slap sieves and 300 slap sieves, and there are single-seat and double-seat sieves for option.

Rotap sieve shaker has two vibration modes of slapping and reciprocating at the same time. The material is fast and the material is not easy to block...

How does Rotap Sieve Shaker work?

Rotap sieve shaker can screen products with various characteristics. It is suitable for the inspection of the particle size composition of ordinary abr...

Five Advantages of Rotap Sieve Shaker

Rotap Sieve Shaker is mainly composed of machine base, sieve and transmission mechanism. It can be equipped with special fixtures, which can be used...

The Rotary Sieve Shaker plays the role of a testing instrument in the laboratory. When the Rotary Sieve Shaker sieves the material, there is a hammer...

What is the cost of rotap sieve shaker?

The price of a rotap sieve shaker ranges from a few hundred dollars to several thousand dollars. The cost depends on the brand, model, capacity...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap