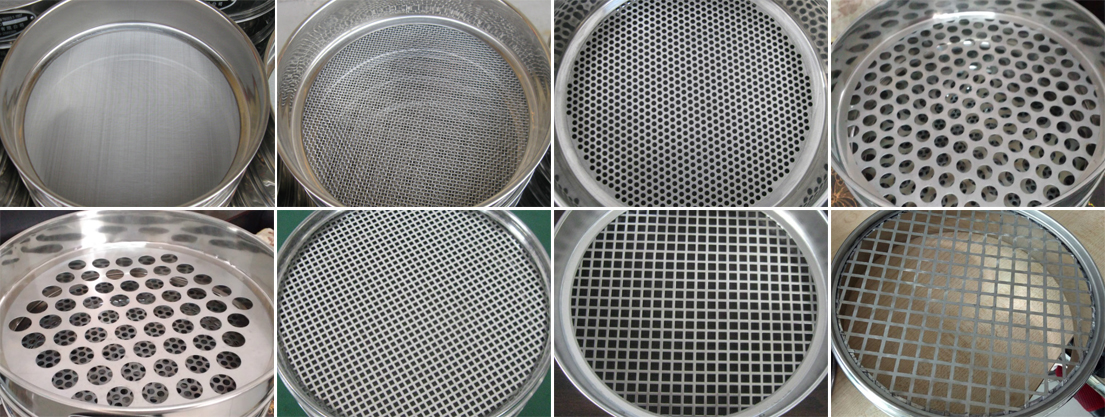

Perforated plate sieve is made of metal perforated plate, also known as perforated plate test sieve, which can be used for the detection of large mesh and large particle materials. The sieve mesh has uniform precision and is not easy to deform. It varies from 0.2mm to hundreds of millimeters.

Price: $9.00-$500.00/SetChat Now

National standard: GB/T6003.2-1997

Sieve Diameter: 200mm, 300mm, 400mm and 450mm

Mesh size: ≤0.2mm

Screen material: brass, tin bronze, stainless steel

Sieve diameter: 75mm, 100mm, 200mm, 300mm, 400mm, 450mm

Materials: detection of large particle materials such as soil, asphalt, coal, sand, aggregate, etc.

About delivery

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

Perforated Plate Sieve is to cut several holes from metal plate (galvanized or stainless steel) for particle sieving, the sieve holes are cut by laser to ensure precision, produced according to national standard GB/T6003.2-1997, in line with international standards ISO3310-2: 1990 R20/3, R20, R40/3 series. Orifice screen, the mesh precision is uniform and not easy to deform, mainly used for the detection of large particles and materials that have an impact on the screen, the material is brass, tin bronze, stainless steel, etc.; there are two types of round holes and square holes, the mesh The hole ranges from 0.2 to several hundred millimeters. It is often used for particle size detection and analysis of large particles or materials that affect the sieve surface. According to different materials to be tested, it can be used such as round-hole asphalt collection sieve, round-hole coal sample sieve, etc.

| product name | Perforated Plate Sieve |

| Screen frame diameter | 75mm/100mm/200mm/300mm/400mm/450mm |

| Aperture size | Round hole: 0.2mm-125mm Square hole: 0.4mm-125mm |

| frame material | Stainless Steel/Brass |

| Perforated Plate Sieve Material | Stainless Steel/Plated Steel |

| high | Full-height and half-height versions |

Perforated plate sieve can be used for materials with relatively large impact on the screen surface and irregular shapes, and is often used for particle size screening and particle size detection in various laboratories, laboratories, article screening, sieving, grading and other inspection departments; Specific materials are: cement clinker, chemicals, coffee, building materials, fertilizers, fillers, flour, grains, metal powders, minerals, nuts, plastics, sand, seeds, soil, washing powder, etc.

Perforated plate sieve has square holes and round holes; it is made of SUS304 (0Cr18ni9) stainless steel stretched and polished, the wall thickness is 0.6mm, the surface is smooth, the overall shape is durable, non-magnetic, and the wire mesh and the wire mesh frame are fixed by welding , no looseness. At the same time, Dahan Machinery also produces slapping standard vibrating sieves and DH-300T test sieve machines matched with φ200 orifice standard sieves. The slap-type standard vibrating screen meets the national standard and can be installed with 8 layers of standard screens. The equipment is equipped with a timer to stop at regular intervals to ensure the consistency of each production or test.

| Perforated Plate Sieve dimensions and perforated metal plate spacing selection tolerance (dimensions: mm) |

||||||

| Nominal sizes of holes, w | Tolerances on individual size of hole | Pitch, p | ||||

| Principal sizes | Supplementary sizes | Preferred sizes | Permissible range of choice | |||

| R 20/3 | R 20 | R 40/3 | pnom | Pmax | pmin | |

| 125 | 125 | 125 | 1 | 160 | 184 | 143 |

| 112 | 0.95 | 140 | 161 | 126 | ||

| 106 | 0.9 | 132 | 152 | 119 | ||

| 100 | 0.85 | 125 | 144 | 113 | ||

| 90 | 90 | 90 | 0.8 | 112 | 129 | 101 |

| 80 | 0.7 | 100 | 115 | 90 | ||

| 75 | 0.7 | 95 | 109 | 85 | ||

| 71 | 0.65 | 90 | 103 | 81 | ||

| 63 | 63 | 63 | 0.6 | 80 | 92 | 72 |

| 56 | 0.55 | 71 | 82 | 63.5 | ||

| 53 | 0.55 | 67 | 77 | 60 | ||

| 50 | 0.55 | 63 | 72.5 | 56.5 | ||

| 45 | 45 | 45 | 0.5 | 56 | 64.5 | 50.5 |

| 40 | 0.45 | 50 | 57.5 | 45 | ||

| 37.5 | 0.45 | 47.5 | 54.6 | 42.5 | ||

| 35.5 | 0.4 | 45 | 51.7 | 40.5 | ||

| 31.5 | 31.5 | 31.5 | 0.4 | 40 | 46 | 36 |

| 28 | 0.35 | 35.5 | 40.8 | 31.8 | ||

| 26.5 | 0.35 | 33.5 | 38.5 | 30 | ||

| 25 | 0.35 | 31.5 | 36 | 28.5 | ||

| 22.4 | 22.4 | 22.4 | 0.3 | 28 | 32.2 | 25.5 |

| 20 | 0.3 | 25 | 29 | 22.5 | ||

| 19 | 0.29 | 23.6 | 27.1 | 21.3 | ||

| 18 | 0.28 | 22.4 | 25.8 | 20.2 | ||

| 16 | 16 | 16 | 0.27 | 20 | 23 | 18 |

| 14 | 0.26 | 18 | 20.7 | 16 | ||

| 13.2 | 0.25 | 17 | 19.5 | 15.1 | ||

| 12.5 | 0.24 | 16 | 18.4 | 14.3 | ||

| 11.2 | 11.2 | 11.2 | 0.23 | 14 | 16.1 | 12.6 |

| 10 | 0.21 | 12.6 | 14.5 | 11.3 | ||

| 9.5 | 0.21 | 12.1 | 13.8 | 10.2 | ||

| 9 | 0.2 | 11.6 | 13.3 | 9.8 | ||

| 8 | 8 | 8 | 0.19 | 10.4 | 12 | 9.2 |

| 7.1 | 0.18 | 9.4 | 10.8 | 8 | ||

| 6.7 | 0.17 | 8.9 | 10.2 | 7.5 | ||

| 6.3 | 0.17 | 8.5 | 9.8 | 7.2 | ||

| 5.6 | 5.6 | 5.6 | 0.15 | 7.7 | 8.9 | 6.6 |

| 5 | 0.14 | 6.9 | 7.9 | 5.9 | ||

| 4.75 | 0.14 | 6.6 | 7.6 | 5.6 | ||

| 4.5 | 0.14 | 6.3 | 7.2 | 5.3 | ||

| 4 | 4 | 4 | 0.13 | 5.8 | 6.7 | 4.9 |

| 3.55 | 0.12 | 5.2 | 6 | 4.4 | ||

| 3.35 | 0.11 | 5 | 5.7 | 4.2 | ||

| 3.15 | 0.11 | 4.7 | 5.3 | 3.9 | ||

| 2.8 | 2.8 | 2.8 | 0.11 | 4.35 | 5 | 3.6 |

| 2.5 | 0.11 | 3.9 | 4.5 | 3.3 | ||

| 2.36 | 0.11 | 3.75 | 4.3 | 3.2 | ||

| 2.24 | 0.1 | 3.6 | 4.1 | 3.1 | ||

| 2 | 2 | 2 | 0.09 | 3.3 | 3.8 | 2.8 |

| 1.8 | 0.08 | 3.1 | 3.6 | 2.7 | ||

| 1.7 | 0.08 | 3 | 3.4 | 2.5 | ||

| 1.6 | 0.08 | 2.75 | 3.2 | 2.3 | ||

| 1.4 | 1.4 | 1.4 | 0.08 | 2.6 | 3 | 2.2 |

| 1.25 | 0.08 | 2.45 | 2.9 | 2.1 | ||

| 1.18 | 0.07 | 2.4 | 2.7 | 2 | ||

| 1.12 | 0.07 | 2.22 | 2.5 | 1.8 | ||

| 1 | 1 | 1 | 0.07 | 2 | 2.3 | 1.7 |

| Note: the lower limit of the nominal size of square holes is 4 mm. | ||||||

1、Difference in material: Perforated plate sieves are usually made of metal materials, such as stainless steel, alloy steel, etc. There are a series of holes on the surface of the perforated plate, through which screening is performed. Screens are also usually made of metal materials, such as stainless steel, alloy steel, etc. The screen is woven from metal wire or metal plate to form a mesh structure, which is used to screen granular materials.

2、Difference in structure: Perforated plate sieve is a flat plate structure with a certain number and arrangement of holes on the surface. Granular materials are screened through the holes. The screen is woven from metal wire or metal plate into a mesh structure, forming a certain sieve hole, and granular materials are screened through the sieve hole.

3、Difference in application: Perforated plate sieves are often used in some occasions where coarse screening is required, and granular materials are preliminarily screened to remove larger particles or foreign matter. Screens are often used for fine screening work. Screens of different mesh sizes can be selected according to different needs to finely screen granular materials.

4、Difference in screening effect: The screening effect of Perforated plate sieve is relatively rough, and is mainly used to remove larger particles or foreign matter. The screening effect of the sieve is finer, and sieves of different mesh sizes can be selected for precise screening as needed.

| Name | Type | Diameter*Height | Frame thickness | National standard | International standard | Application |

| Test sieve | Woven wire mesh | 200*50 200*25 | 0.6-0.7 | GB6003.1-1997 | ISO3310 | Precise screening and particle size measurement of granular materials |

| Test sieve | Perforated metal sheet | 200*50 200*25 | 0.6-0.7 | GB6003.2-1997 | ISO3310 | Chemical industry |

1. Frame material and process: Made of 304 stainless steel, it is stretched and polished, with excellent corrosion resistance and high temperature resistance, ensuring long-term stable operation of the equipment.

2. Screen material and structure: The screen is made of round or square hole punching plate, with precise aperture, stable size, and can withstand high temperature environment.

3. Connection between frame and screen: The screen is firmly fixed to the frame by welding process to ensure that the screen does not loosen during vibration and extend the service life of the equipment.

4. Compliance with international standards: The screen complies with international standards such as ISO3310, ASTM, BSI, DIN, JIS, etc. to ensure product quality and performance.

Punching plate screen, high pressure resistance, strong and durable, not easy to deform

Made of stainless steel, it is resistant to acid, alkali and salt corrosion, and can withstand high temperatures below 300 °C.

The screening precision is high and can be screened to 325 meshes.

Light weight, small size, easy to move.

It can be installed with 8 layers, and the screen mesh and the screen frame are fixed by soldering without loosening.

Tolerance for individual hole dimensions for each hole in perforated metal plate in Perforated plate sieve. Using appropriate equipment, measure the hole size with a reading accuracy of 20 μm or 1/4 of the relevant tolerance, whichever is greater.

Test 1—Visual Inspection of General Conditions

View perforated metal sheets against an evenly lit background. Screens are unacceptable if significant deviations in appearance uniformity are found, such as partial holes (4 mm and larger).

Test 2—Measurement of Hole Size and Spacing

Measure the hole size on the centerline of the square hole and the diameter of the round hole.

| Minimum number of holes measured on a Perforated plate sieve with a diameter of 200 mm | ||

| Nominal sizes of holeswmm | Process for compliance and inspection | Process for calibration |

| 125 to 22.4 | All (max. 25 in larger sieves with diameter more than 200 mm) | All (max. 50 in larger sieves with diameter more than 200 mm) |

| 20 to 4 | 2 × 15 | 2 × 30 |

| 3.55 to 2.24 | 2 × 20 | 2 × 40 |

| 2 to 1.6 | 2 × 25 | 2 × 50 |

| 1.4 to 1 | 2 × 40 | 2 × 80 |

On any selected area of the Perforated plate sieve, measure the size and spacing p of the holes along two straight lines and in different directions, each line having a length of at least 150 mm and including at least eight holes in each direction.

If the size of any hole is out of tolerance, the sieve is not acceptable.

If there is no minimum number of inspection holes specified on the plate, inspect all holes in the sieve.

Dahan Perforated Plate Sieve Manufacturer sells Perforated Plate Sieve, stainless steel Perforated Plate Sieve, round hole Perforated Plate Sieve, square hole Perforated Plate Sieve, brass Perforated Plate Sieve, etc., the diameter is 75mm, 100mm, 200mm, 300mm, 400mm, 450mm, etc., the material There are stainless steel, brass, tin bronze, etc., factory direct sales, the price is cheap.

Mesh size: 2.36mm-0.038mm

Price: $10.00-$200.00/Set

Detection range: 0.075mm-100mm

Price: $20.00 - $200.00/set

Screening particle size: 0.025-3mm

Price: $650.00 - $800.00/Set

Aperture size: 2.36-0.038mm

Price: $5-$500/Set

Introduction of Perforated Plate Sieve

A Perforated Plate Sieve is a sieve commonly used for filtering and sifting materials. It has the characteristics of a perforated plate inner diameter of 3mm to 5mm and a plate...

Mesh Type of Test Sieve Shaker

Test Sieve Shaker is mainly used in various laboratories, laboratories, item screening, sieving, grading and other inspection departments to accurately sieve and filter the p...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap