Thursday February-27 2025 11:28:16

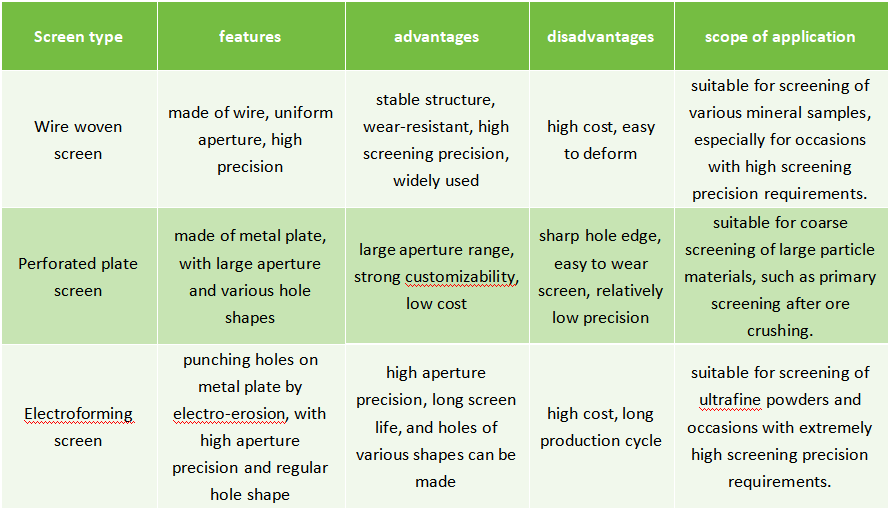

Mineral Analysis Test Sieve is an important tool specially used for mineral particle size analysis and classification, and is widely used in mining, geology, metallurgy and other fields. Through sieves with different apertures, mineral particles can be separated according to particle size, so as to obtain the particle size distribution of minerals, providing important data support for mineral processing and mineral processing

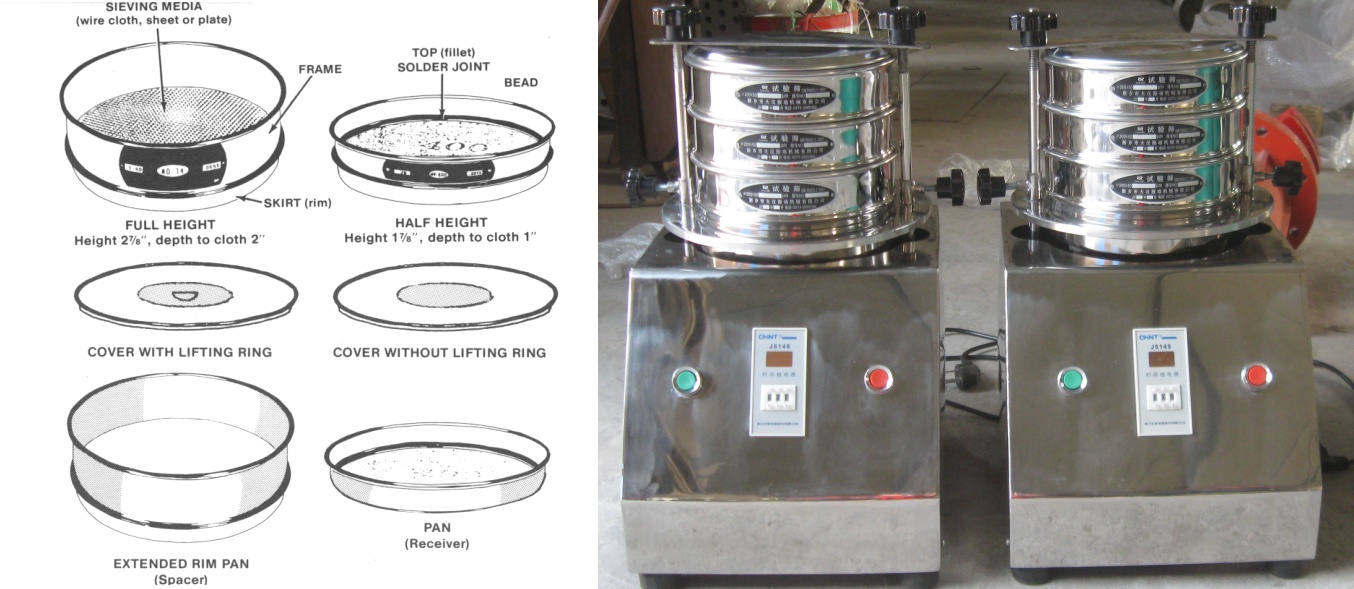

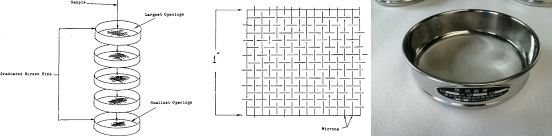

Mineral Analysis Test Sieve generates vibration through the vibration motor, which makes the screen box vibrate. Under the action of vibration, the mineral particles keep jumping on the screen surface and pass through the pores of the screen. Particles larger than the pore size of the screen are retained on the screen, and particles smaller than the pore size of the screen pass through the screen and fall into the next layer or collection container. By superimposing screens with different pore sizes, mineral particles can be classified into multiple levels according to particle size.

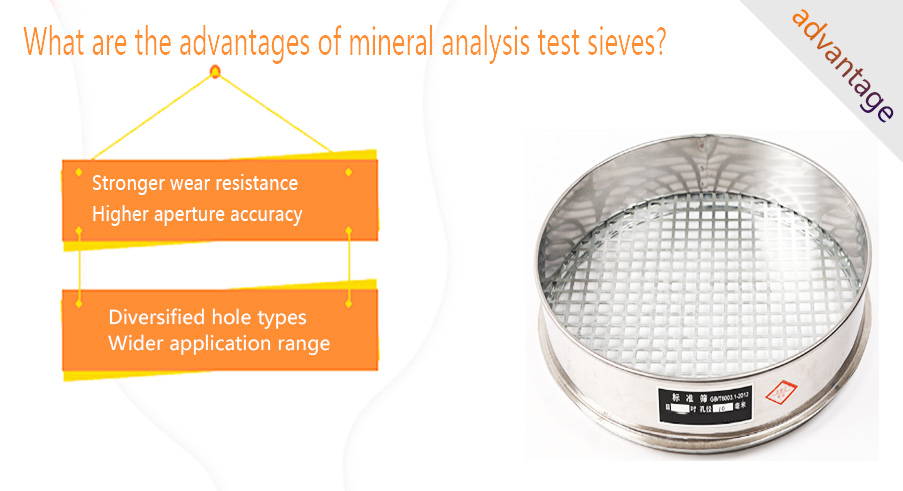

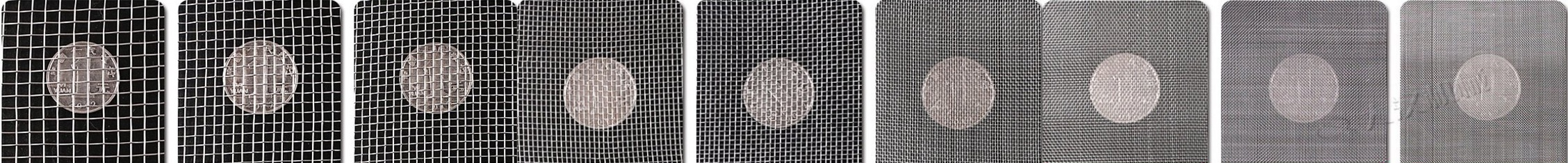

1、Stronger wear resistance: Mineral particles are often harder and cause greater wear on the screen. Mineral analysis test sieves are usually made of stainless steel and other materials with stronger wear resistance to extend the service life of the screen.

2、Higher aperture accuracy: In order to accurately analyze the particle size distribution of mineral particles, the sieve aperture of the mineral analysis test sieve is more accurate and has a smaller error.

3、Diversified hole types: In addition to the common round hole screen, there are also square, rectangular and other hole types to meet the screening needs of different minerals

4、Wider application range: From coarse-grained ore to fine-grained powder, efficient screening can be performed, not only for particle size analysis, but also for mineral density sorting, magnetic separation and other experiments.

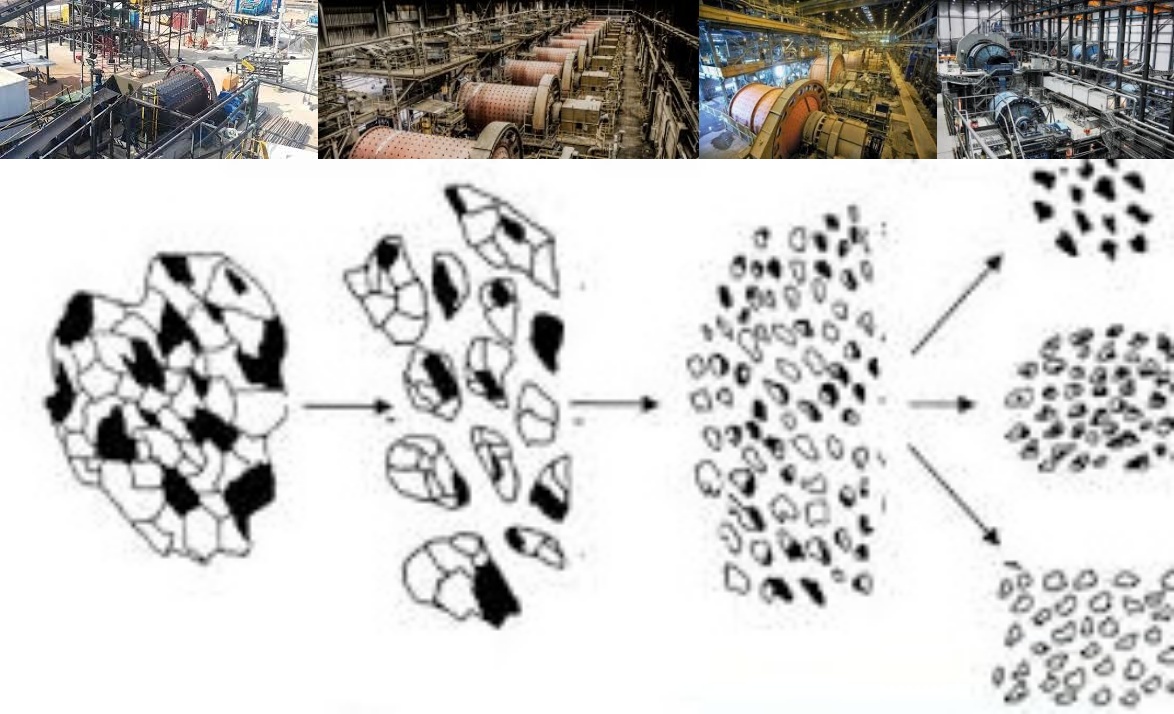

1. Mineral processing: Through screening analysis, the optimal particle size for ore crushing and grinding can be determined, thereby improving the efficiency and recovery rate of mineral processing. For products that require a specific particle size, such as corundum, abrasives, etc., screening can ensure the quality of the product.

2. Mineral beneficiation: According to the particle size differences of different minerals, graded beneficiation is carried out to improve the efficiency of mineral processing. In the process of re-selection, screening can remove oversized or undersized particles and improve the effect of mineral processing.

3. Mineral identification: Through screening analysis, the type and properties of minerals can be preliminarily determined. For example, for placer gold ore, the grade and occurrence state of gold can be determined based on the particle size distribution of gold particles.

4. Ore deposit evaluation: Through screening analysis of ore samples, the mineral composition and particle size distribution of the ore deposit can be understood, providing important data for ore deposit evaluation.

5. Environmental monitoring: For mine wastewater, tailings, etc., screening analysis can be used to understand the particle size distribution of particles in them and evaluate their impact on the environment.

Because particle size analysis is the basis of mineral processing, different mineral particle sizes require different processing techniques. For example, for coarse-grained minerals, crushing may be required first, while for fine-grained minerals, grinding and other processes are required. Different crushing and grinding equipment are required for different particle size ranges. Through screening analysis, the recovery rate of minerals of different particle sizes can be evaluated to optimize the process flow.

Minerals of different particle sizes have different physical and chemical properties. Through screening analysis, the particle size distribution of minerals can be understood, providing data support for subsequent mineral processing tests. The particle size composition of ore is one of the important parameters for ore deposit evaluation, which can reflect the formation conditions and mineral characteristics of the ore deposit.

Prepare samples: Get representative samples from mineral materials such as ore and slag. According to the test requirements, crush and grind the samples appropriately to ensure that the particle size is suitable for the test sieve requirements.

Prepare test sieves: Select test sieves of appropriate specifications and use single or multi-layer sieves as needed. Clean and calibrate the test sieves to ensure that the sieve holes are not blocked or damaged.

Loading sieves: Stack the prepared test sieves from top to bottom in order of particle size. Place a receiving container or bottom sieve to collect particles of different particle size ranges.

Screening operation: Place the sample in the top sieve. Cover the sieve cover, start the screening equipment (such as vibrating screen, rotary screen, etc.), and perform particle screening operations. The screening time depends on the nature of the sample and the test requirements, and it is usually necessary to ensure sufficient screening.

Particle collection: After the screening is completed, collect the particles on each layer of the sieve and record the mass or weight of the particles in each sieve hole.

Data processing: Weigh or count the collected particles and calculate the content ratio of particles in each particle size range. Draw the particle size distribution curve and analyze the particle size characteristics and distribution law of the particles.

Result analysis: According to the particle distribution analysis results, evaluate the particle size and particle size distribution characteristics of the mineral material to provide reference for engineering design, production and research.

The importance of mineral analysis test sieves in mineral processing is reflected in its accurate analysis of the particle size distribution of ore particles, which provides important technical support and data basis for the optimization of ore processing technology, product quality control and process improvement.

laboratory test sieve is also called standard sieve, test sieve, laboratory vibrating screen, sample sieve, inspection sieve, standard analysis sieve...

What Is An Electromagnetic Sieve Shaker?

Electromagnetic sieve shaker is a screening equipment used for testing and laboratory research. It is often used to screen and classify small batches...

Test sieve shaker is a laboratory equipment used for particle screening and classification, also known as laboratory shaker or laboratory vibrating...

Phosphate Test Sieve is an experimental tool used to screen different particle sizes in phosphate samples and detect the phosphate...

304 stainless steel soil test sieve

304 stainless steel soil test sieve is a professional screening equipment specially used for soil particle size analysis, particle...

Feb 27, 2025

Laboratory powder test sieve is an essential instrument used for screening and grading powder or gran...

Feb 27, 2025

Soil Aggregate Sand Test Sieve

What is a soil aggregate sand test sieve? Soil aggregate sand test sieve is an instrument specially u...

Feb 27, 2025

What is a mineral analysis test sieve? Mineral analysis test sieve is an important tool specially use...

Feb 27, 2025

Drug test sieve is a screening device specially used in drug research and production. It is mainly us...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap