Thursday February-27 2025 09:38:05

Metal powder test sieve is a device used for accurately measuring the particle size distribution of metal powder. It separates metal powder into different particle size levels through a series of mesh screens with precise mesh sizes. It is usually used for particle size analysis and screening of metal powder in laboratories or production sites. This type of test sieve is usually made of stainless steel or other corrosion-resistant metals to ensure that the screening process of metal powder does not cause contamination or corrosion.

1. Particle size analysis: By using a metal powder test sieve, metal powders can be classified according to particle size to understand their particle size distribution.

2. Screening: Metal powder test sieve can screen the original metal powder to remove impurities or oversized particles, in order to obtain metal powder that meets the requirements.

3. Quality control: By using metal powder test sieves, the quality of metal powder can be controlled and monitored to ensure that the quality of metal powder meets standard requirements during the production process.

4. Experimental research: Metal powder test sieves are also commonly used in scientific research laboratories to study the physical properties and particle distribution patterns of metal powders.

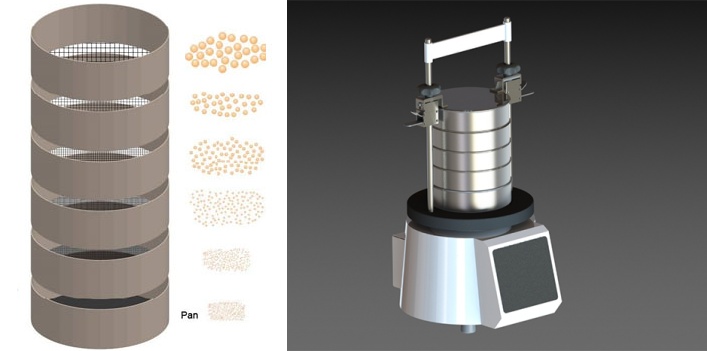

Place a certain amount of metal powder on top of the test sieve. By using the vibration effect of the metal powder test sieve, the metal powder is passed through the sieve. Different particle sizes of powders are separated into different sieve layers, and by measuring the weight of the powder in each sieve layer, the particle size distribution of the metal powder can be calculated.

1. High precision screening: Metal powder test sieve adopts standardized sieve mesh with precise mesh size, which can finely classify metal powder and achieve high-precision particle size measurement. It is suitable for particle screening from micrometer to millimeter level.

2. Standardization: Metal powder test sieves typically comply with international standards such as ASTM and ISO to ensure the reliability and comparability of measurement results.

3. Diversity: Metal powder test sieve provides multiple screen sizes and screening methods to meet the measurement needs of different metal powders. Provide screens with different aperture sizes to meet the screening needs of different particle size ranges.

4. Durability: Metal powder test sieves are usually made of durable materials such as stainless steel, which can withstand long-term use, friction and impact of metal powder, and extend their service life.

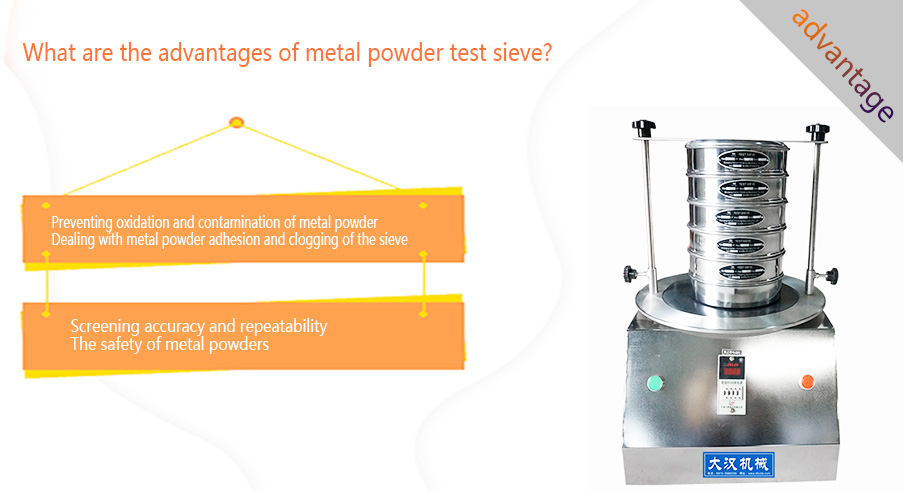

1. Preventing oxidation and contamination of metal powder: Metal powder is prone to contact with air during the screening process, leading to oxidation or contamination by other impurities, which affects the quality of the powder. Metal powder test sieves usually adopt a closed design to reduce the contact between powder and air.

2. Dealing with metal powder adhesion and clogging of the sieve: Metal powder, especially fine powder, is prone to adhere to the sieve due to static electricity, humidity, or irregular particle shape, causing the sieve to clog and affecting screening efficiency and accuracy. Metal powder test sieves are usually made of materials such as stainless steel and undergo special surface treatment to reduce powder adhesion.

3. Screening accuracy and repeatability: The particle size distribution of metal powder is crucial for product quality and requires precise measurement. Metal powder test sieve adopts high-precision mesh to ensure screening accuracy. Metal powder test sieve can accurately control the screening time and vibration parameters, reduce human errors, and improve the repeatability of screening results.

4. The safety of metal powders: Some metal powders have flammable, explosive, or toxic properties, and there are safety hazards during the screening process. For flammable and explosive metal powders, the test sieve adopts explosion-proof design to ensure safe operation. For toxic metal powders, metal powder test sieve is equipped with a ventilation system to reduce the exposure risk for operators.

Metal powder production: In the process of metal powder production, metal powder test sieves are commonly used for particle size analysis and screening of the produced metal powder to ensure that it meets production requirements.

Metal processing: In the metal processing industry, metal powder test sieves can be used to screen different metal powders to meet the particle size requirements of different processing techniques.

Research on the Application of Metal Powder: In scientific research institutions or laboratories, metal powder test sieves are commonly used for particle analysis and research of metal powders to explore their potential applications in materials science and engineering.

Quality control of metal powder: Metal powder test sieves are also widely used in the quality control process of metal powder production enterprises. By monitoring and screening the particle size of metal powder, product quality stability is ensured.

Metal powder screening: During the mixing, packaging, or transportation process of metal powder, a metal powder test sieve can be used to screen the metal powder, remove impurities or unqualified particles, and ensure product quality.

Metal powder recycling: Metal powder test sieves can also be used in the process of metal powder recycling. Through screening and grading, waste metal powder can be reused to reduce resource waste.

1. Powder metallurgy: Metal powder test sieve is used to screen metal powders such as iron powder, copper powder, aluminum powder, tungsten powder, etc., to ensure that the powder particle size meets the requirements of sintering, compression molding, or injection molding. The particle size distribution directly affects the density, strength, and surface quality of metal parts. By conducting experimental screening, the flowability, filling ability, and formability of the powder can be optimized.

2. 3D printing (additive manufacturing): Metal powder test sieve is used to screen metal powders such as titanium alloys, nickel based alloys, aluminum alloys, stainless steel, etc., ensuring uniform particle size and meeting the requirements of 3D printing technology. 3D printing has extremely high requirements for the particle size distribution of metal powders. The experimental sieve can remove particles that are too large or too small, ensuring the flowability and uniformity of the powder, and improving the accuracy and surface quality of the printed parts.

3.Battery manufacturing: Metal powder test sieve is used to screen metal powder in lithium batteries or fuel cells to ensure the uniformity of electrode materials. The particle size distribution of electrode materials directly affects the performance and lifespan of batteries. It can remove impurities and unqualified particles, improve the energy density and cycling stability of batteries.

4. Surface coating: Metal powder test sieve is used to screen metal powder for thermal spraying, cold spraying or plasma spraying, and the coating quality is closely related to the powder particle size. The metal powder test sieve can ensure uniform particle size of the powder, improve the adhesion, density, and corrosion resistance of the coating.

5. Laboratory research and development: Metal powder test sieve is used for particle size analysis and quality control of metal powders in the laboratory, to study the properties of new materials. Metal powder test sieve is a commonly used particle size analysis tool in the laboratory, which can help personnel understand the particle size distribution of metal powder, optimize material formulation and process parameters.

Preparation of sieve: Select a suitable sieve based on the particle size range of the metal powder, usually using a combination of multiple layers of sieve (gradually decreasing from top to bottom).

Sample loading: Place the metal powder sample into the topmost sieve.

Start the equipment: Turn on the metal powder test sieve, and the metal powder passes through the sieve under vibration, layering according to particle size.

Collect samples: After screening, collect the powder from each layer of the sieve, weigh it, and record the data.

Analysis results: Based on the screening results, analyze the particle size distribution of the metal powder and evaluate whether it meets the process requirements.

Metal powder test sieve is an indispensable tool in the production and research and development of metal powder, which can effectively screen and analyze the particle size distribution of metal powder, ensuring product quality and process stability. Its high precision, wear resistance, and ease of operation make it widely used in fields such as powder metallurgy, 3D printing, and chemical engineering.

laboratory test sieve is also called standard sieve, test sieve, laboratory vibrating screen, sample sieve, inspection sieve, standard analysis sieve...

What Is An Electromagnetic Sieve Shaker?

Electromagnetic sieve shaker is a screening equipment used for testing and laboratory research. It is often used to screen and classify small batches...

Test sieve shaker is a laboratory equipment used for particle screening and classification, also known as laboratory shaker or laboratory vibrating...

Phosphate Test Sieve is an experimental tool used to screen different particle sizes in phosphate samples and detect the phosphate...

High precision subdivision test sieve

High precision subdivision test sieve is a device used in the laboratory to perform fine particle size analysis on granular and powdery...

Feb 27, 2025

Metal powder test sieve is a device used to accurately measure the particle size distribution of meta...

Feb 25, 2025

What is a ceramic powder test sieve? Ceramic powder test sieve is a screening device used to accurate...

Feb 24, 2025

High precision subdivision test sieve

High precision subdivision test sieve is a device used in the laboratory to perform fine particle siz...

Feb 24, 2025

Aluminum powder laboratory test sieve

Aluminum Powder Laboratory Test Sieve is a device used for aluminum powder particle size analysis and...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap