Thursday February-23 2023 14:50:10

Test Sieve Shaker is mainly used in various laboratories, laboratories, item screening, sieving, grading and other inspection departments to accurately sieve and filter the particle size structure, liquid solid content and sundry content of granular and powdery materials. , Detection. The following editor will introduce to you how many types of meshes are there in the standard test sieve?

The most widely used mesh - square hole from 2.36mm to 0.02mm

Wire woven mesh has the lowest cost and good flexibility, but the relative accuracy is the lowest (large mesh is allowed), and the mesh may be deformed. The mesh precision can be controlled by expanding and shrinking holes, and the holes can be fixed by electrochemical methods. Generally, manufacturers with high-precision screen production capacity are required to ensure mass production. The most widely used industry is the diamond industry, especially the export manufacturers require a standard negative difference, because foreign countries are half a size away from China, and basic grains account for more than 90%. .

Mainly used in large meshes - round holes and square holes from 0.2mm to hundreds of mm

The punching plate screen refers to the screen that uses a punch to punch out the target pattern in the plate to be processed. The material is stainless steel, aluminum plate, cold and hot steel plate, copper plate, PVC plate film, etc. The mesh accuracy of the punching plate screen is Uniform and not easy to deform, mainly used for the detection of large particles. The hole types include long holes, round holes, square holes, triangular holes, scale holes, bridge holes, diamond holes, pentagonal holes, hexagonal holes, figure-eight holes, cross holes, nails There are many kinds of holes, plum blossom holes, herringbone holes, I-shaped holes and other special-shaped holes.

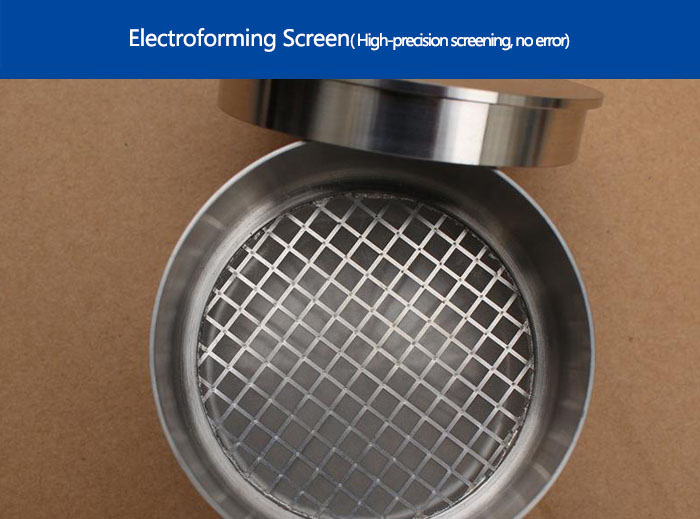

Mainly used for high-precision screening - can make each mesh within the average error range

Electroforming screens are manufactured by electrochemical methods, with the highest precision. Theoretically, the precision can reach one micron. The biggest feature is that the screen holes of the rigid structure will not be deformed. The particle size distribution using electroformed filter material is significantly narrower, requires cleaner and less maintenance than woven wire mesh filter material, allows longer filter time and service life to greatly improve production efficiency. It has a very wide range of applications in high-precision laboratory particle size detection scenarios.

The above is the introduction of the three mesh types of Test Sieve Shaker.

How to choose Test Sieve Shaker

The selection of materials depends on the characteristics. The users demand for the product will largely indicate the functions of a product. Faced with many types of Test Sieve Sha...

Test Sieve Shaker is an instrument for detecting and analyzing the particle size structure and particle size distribution of 2kg of material in the test sieve. Test Sieve Shaker Pro...

Feb 23, 2023

Mesh Type of Test Sieve Shaker

Test Sieve Shaker is mainly used in various laboratories, laboratories, item screening, sieving, grad...

Feb 23, 2023

Slap Type Test Sieve is mainly used in laboratories within universities/research institutes/enterpris...

Feb 23, 2023

Slap Type Test Sieve Structure and Principle

Slap Type Test Sieve is mainly composed of slap hammer, hammer stroke adjustment lever, hammer transm...

Feb 22, 2023

How to choose Test Sieve Shaker

The selection of materials depends on the characteristics. The users demand for the product will larg...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap