Laboratory test sieves is an instrument for measuring particle size and particle size distribution. The common form consists of a woven wire mesh with square holes mounted in a shallow cylindrical rigid metal frame.

$20.00-$936.00/SetChat Now

Measuring range: 125 mm - 20 μm (minimum 5 μm)

Screen diameter: 75mm, 100mm, 200mm, 300mm, 400mm

Screen depth: 32, 50 or 65 mm

Round hole: 0.5 to 125 mm (stainless steel)

Square hole: 4.0 to 125 mm (stainless steel)

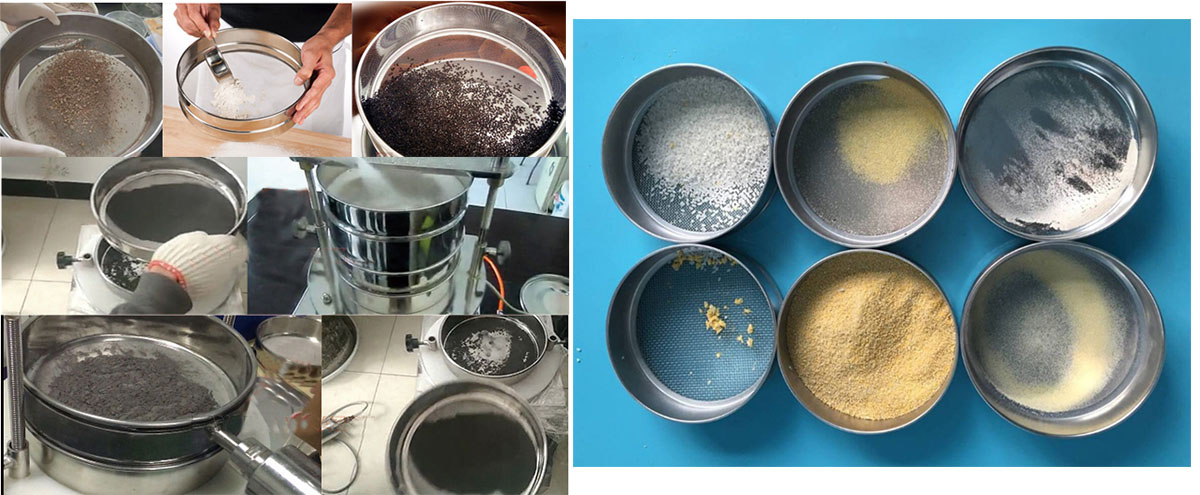

Applications: Detection and analysis of particle size distribution of materials, sample preparation, fractionation, such as: powders, aggregates, suspensions, seeds, etc.

For precision testing and screening of laboratory materials

Particle size from 20 μm to 125 mm can be measured, and special sieves with apertures smaller than 20 μm can also be used, and the finest sieve is 5 μm.

1-8 sieve frames are optional, and one material can be sieved into 2-7 particle size sections at a time.

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

Laboratory test sieves is a commonly used laboratory instrument used to sieve granular or powdered materials to obtain particles of different particle sizes.Through screening analysis, the particle size distribution data of the material can be obtained, providing an important reference for subsequent experimental research.

Laboratory Test Sieves is an instrument commonly used in laboratories to detect the particle size of chemicals, powders, oils and other fluid materials; and can quickly and efficiently measure the particle size of solids from 125 mm to 20 μm. Special sieves with pore sizes smaller than 20 μm can also be used, but the finer the sieve, the more likely certain types of particulate solids will block the pore size. Here we can use a special technique "micro" sieving down to 5 μm.

1. Development of particle size distribution curve: Test sieves are equipped with progressive small holes to separate small parts. Using test sieves, particles can be distinguished according to their different sizes, so as to accurately obtain the particle size distribution curve.

2. Utilization based on vibrating screens: Vibrators produce vibrations or oscillations in a specific range.

3. Particle differentiation based on mesh size: Test sieves are designed with different mesh sizes to separate particles of different sizes or only particles of a specific size.

| name | Laboratory Test Sieves |

| Sieve Diameter | 300mm (12 inches)/200mm (8 inches)/100mm (4 inches)/75mm (3 inches) |

| material | Stainless Steel, Brass |

| interior height | 50 mm,60mm |

| Aperture size range | 0.02mm-125mm |

| Screen material | Weaving nets, punching plates, electroforming |

| hole type | square hole, round hole |

| Specification | 125, 106, 100, 90, 75, 63, 53, 50, 45, 37.5, 31.5, 25, 22.4, 19, 16, 13.2, 12.5, 11.2, 9.5, 8, 6.7, 6.3, 5.6, 4.75, 4, 3.35, 2.8, 2.36, 2, 1.7, 1.4, 1.18, 1, 0.85, 0.71, 0.6, 0.5, 0.425, 0.355, 0.3, 0.25, 0.212, 0.18, 0.15, 0.125, 0.106, 0.09, 0.075, 0.063, 0.053, 0.045, 0.038mm etc. |

| Use | Grading Standard Testing Sieve,Test Sieve for soil test sieve, aggregate sieve, concrete test sieve, cement test sieve, asphalt test sieve, wet sieve, wire mesh sieve, perforated sieve, astm sieve, en sieve |

| Classification | picture | product description | Sieve mesh (precision) | diameter |

| Ordinary laboratory test sieves |  |

Various experimental objects within 400 meshes are accurately screened.The standard vibrating sieves equipped with common soil sieves,gravel sieves and pharmacopoeia sieves are all standard test sieves. | 0.025mm-3mm | 75/100/300/400mm |

| Ultrasonic laboratory test sieves |  |

The ultrasonic energy conversion system is installed,which can solve the problem of blocking the network of materials with strong adsorption,easy clumping, high static electricity, high density and light specific gravity.The sieving can be as fine as 500 mesh,and the accuracy can be increased by 90%. | 500 mesh | 200mm/300mm |

| Rotap sieve shaker |  |

It adopts the form of slapping (topping) and reciprocating double motion,and the material is unloaded quickly, and it is not easy to block the screen surface.It is suitable for screening fine materials, especially viscous materials, but the noise is relatively large. | Slap times: 156 (+-) 3 times/min | 200/300mm |

| Electromagnetic laboratory test sieves |  |

Using electromagnetic vibration, the screen surface vibrates up and down at high frequency,the vibration frequency reaches 3000 times/min,the material is not easy to stick to the mesh,and it can be screened to 20um (635 mesh).The negative pressure device can dry sieve the material to 5um, which can solve the problem that the ultrafine powder is difficult to dry sieve. | 5μm | 75/100/ 200mm |

| Magnetic levitation laboratory test sieves |  |

Mechanical physical movement + high-frequency electromagnetic vibration,three movements of up and down vibration, front and rear reciprocating movement,and left and right swinging can be carried out at the same time,so that the material has a reciprocating rotation movement, no hole blocking,no residual material on the screen, and can be screened to 5 microns.It can feed 200g at a time, and can be equipped with 8 layers of screen frame. | 2500 mesh to fine or 5 microns | 75/100/ 200mm |

Wire Woven Mesh Laboratory Test Sieves

National standard: GB/T6003.1-1997, ISO3310-1: 1990 R20/3, R20, R40/3 series

Mesh size: 2.36mm-0.038mm

Screen frame diameter: 75/200 mm/300 mm

Screen material: brass, tin bronze, stainless steel

Application: high-precision screen, mostly used in diamond industry

Metal Perforated Sheet Laboratory Test Sieves

National standard: GB/T6003.2-1997, ISO3310-2: 1990 R20/3, R20, R40/3 series

Mesh size: 1mm-125mm

Screen frame diameter: 200 mm/300 mm

Screen material: copper

Application:Large particles, material particle size detection that has impact on the screen surface

Electroforming Laboratory Test Sieves

National standard: GB/T6003.3-1999/ISO3310.3

Mesh size: 5μm-500μm (fine tolerance of mesh size 2-3um)

Diameter of screen frame: 75mm

Screen material: stainless steel

Application: fine powder detection, commonly used in laboratories

Laboratory Test Sieves can be used for particle size testing and particle size analysis of powdery, granular and liquid materials from 125mm to 20μm. It is commonly used in food, chemical, pharmaceutical, metallurgical and other industries. The specific materials are as follows.

Food industry: flour, cocoa, coffee, condiments, additives, corn, sesame, etc.

Pharmaceutical industry: Chinese and Western raw materials, Western medicine, Chinese medicine, etc.

Chemical industry: resins, plastics, rubber additives, dyes, fillers, phosphors, etc.

Metallurgical industry: lead, zinc, copper, iron, nickel, alloys, magnetic materials and other metal powders.

Abrasive industry: glass beads, alumina, corundum, chlorine carbon, emery, quartz sand, etc.

Laboratory test sieves are designed to meet the strict standards of the International Organization for Standardization (ISO) 3310-1, or the American standard ASTM E-11. In addition, precision electroformed sieves meet the ASTME161 standard, while perforated plate sieves meet the ASTME323 or British Standard BS140-1 and ANSI2000 standards.

1. It can be used to analyze the fineness and foreign matter content of powder or slurry material.

2. It is made of SUS304 stainless steel by stretching and polishing, with a wall thickness of 0.6 mm, non-magnetic, and high temperature resistance below 300 ℃. The screen and screen frame are fixed by soldering, which is not easy to loosen.

3. In the inspection process, the screening accuracy is accurate and the screening efficiency is high, which can be screened to 0.025-3mm.

4. Laboratory test sieves can be automatically shut down at regular intervals to ensure test repeatability and comprehensive functions.

5. Platform operation, no need to fix, low noise, light weight, easy to place and move.

Mesh is a measurement of particle size, and then it’s often used for determining the particle size distribution of a granular material in sieve analysis or gradation test.

Mesh number is also known as sieve number. The numerical value indicates the number of openings / holes per linear inch of a stainless steel woven wire mesh. For instance,

The steel screen used in 8 mesh sieve has 8 holes per linear inch in both directions.

The ss screen used in 10 mesh sieve possesses 10 openings per inch in both sides.

The stainless steel mesh used in 20 mesh sieve has 20 holes per inch.

The wire mesh stainless steel used in 50 mesh sieve has 50 openings per inch.

There are 60 holes per inch for the steel screening mesh of 60 mesh sieve.

The ss screen of 100 mesh sieve has 100 openings per linear inch.

There are 120 holes per inch for the stainless steel wire screen of 120 mesh sieve.

The mesh screen of 325 mesh sieve has 325 openings per inch.

The steel screen of 400 mesh sieve possesses 400 holes per inch.

The ss screen of 500 mesh sieve has 500 openings per linear inch in both directions.

And so on.

| Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) |

| 2 | 13 | 26 | 0.71 | 90 | 0.16 | 260 | 0.06 |

| 3 | 6.5 | 28 | 0.63 | 100 | 0.154 | 280 | 0.055 |

| 4 | 5 | 30 | 0.6 | 110 | 0.14 | 300 | 0.054 |

| 5 | 4 | 32 | 0.55 | 115 | 0.13 | 320 | 0.048 |

| 6 | 3.2 | 36 | 0.5 | 120 | 0.125 | 325 | 0.045 |

| 7 | 2.8 | 40 | 0.45 | 130 | 0.111 | 350 | 0.041 |

| 8 | 2.5 | 45 | 0.4 | 140 | 0.105 | 360 | 0.4 |

| 9 | 2.2 | 50 | 0.355 | 150 | 0.1 | 400 | 0.0385 |

| 10 | 2 | 55 | 0.315 | 160 | 0.098 | 500 | 0.03 |

| 12 | 1.6 | 60 | 0.3 | 180 | 0.09 | ||

| 14 | 1.43 | 65 | 0.25 | 190 | 0.08 | ||

| 16 | 1.25 | 70 | 0.22 | 200 | 0.075 | ||

| 18 | 1 | 75 | 0.2 | 220 | 0.07 | ||

| 20 | 0.9 | 80 | 0.18 | 240 | 0.065 | ||

| 24 | 0.8 | 85 | 0.17 | 250 | 0.063 |

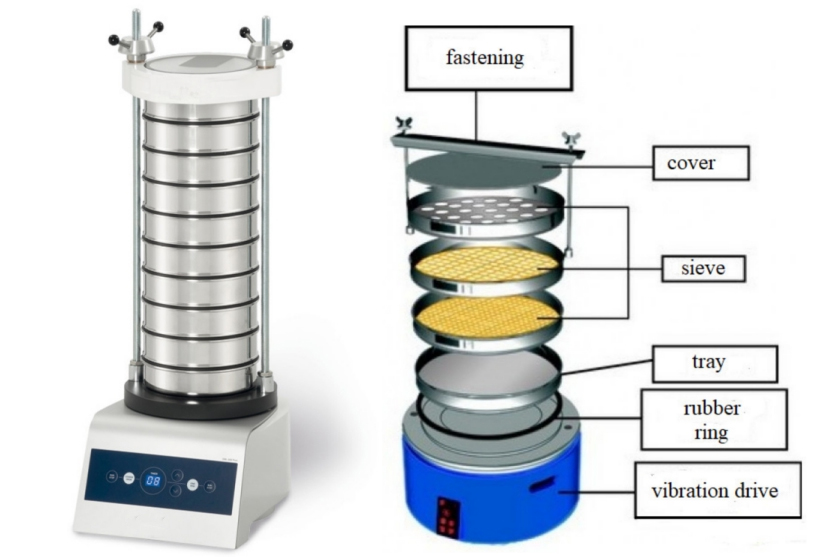

The upper part of Laboratory test sieves is composed of fixed brass nuts, pressure plate, sieve cover, sieve frame, middle sieve frame, sieve bottom, isometric adjustment rod and so on.

Screen frame: There are two kinds of diameters: 200mm and 300mm. The commonly used one is 200mm, but some users have special requirements and also have 75mm. Can prevent 8 floors of labs.

Screen: The mesh of Laboratory test sieves is 8 to 500 mesh. The larger the mesh, the smaller the hole. Therefore, according to the size of the mesh, there are two kinds of punching plate and wire mesh. A small mesh is a punching plate, and a large mesh is a wire mesh.

Time relay: 0-99 minutes automatic timing to ensure test repeatability.

When Laboratory Test Sieves is working, the vibration motor is used as the vibration source, and the vibration of the vibration motor drives the spring to vibrate, and finally the vibration force is transmitted to the screen frame, so as to realize the particle size detection of the material and ensure the accurate detection of the content and the amount of sundries. The production process provides more scientific and reliable theoretical data.

Dahan laboratory test sieves suppliers is a manufacturer integrating production, research and development, and sales, specializing in the sale of laboratory test sieves, the diameter of the screen is 75mm, 100mm, 200mm, 300mm, 400mm optional, the material is stainless steel, brass, nylon, etc. . Our factory also accepts product customization, such as: ultrasonic laboratory test sieves (special for ultra-fine powder, without blocking the mesh), electromagnetic laboratory test sieves (dry screening to 5 microns), etc.

| serial number | name | unit | parameter |

| 01 | sieve frame | layer | 1~5 |

| 02 | screen frame diameter | mm | 300,200,100 |

| 03 | sieve particle size | mm | 0.025~3 |

| 04 | noise | dB | less than 50 |

| 05 | amplitude | mm | 0~3 |

| 06 | vibration frequency | times/min | 1400 |

| 07 | external dimensions | length*width*height | 350:350:300+N*50 |

| 08 | power supply | V;HZ | 220;50 |

| 09 | machine weight | Kg | 36 |

| 10 | Vibration motor | Power | 0.12KW |

When purchasing a test sieve, you need to know the following information to help you choose the right laboratory test sieve.

1. Mesh size

2. Number of test sieves

3. Number of samples required

4. Whether a screening machine is required

5. How long the test sieve is used

6. Is the test sieve certified or calibrated

Screening particle size: 0.025-3mm

Price: $650.00 - $800.00/Set

Screening particle size: 0.025-3mm

Price: $538.00 - $925.00/Set

Mesh sizes: 20 microns-5 mm

Price: $656.00 - $975.00/Sets

Screening particle: 0.025-3 mm

Price: $23.00-$850.00/Set

Laboratory Test Sieves Manufacturers

Laboratory Test Sieves Manufacturers choose Dahan Machinery! Dahan Laboratory Test Sieves Manufacturers has more than 15 years of experience in test sieve research and development, ...

What problems should I pay attention to when purchasing laboratory test sieves?

The introduction as follows: Laboratory test sieves of purchase notice: Tip 1: the purpose of screening: If you are purchasing for the laboratory, you must require exquisite appeara...

Nylon plastic for laboratory test sieves

Laboratory test sieves overview: Laboratory test sieves , also known as plastic nylon sieves, are laboratory sample separation equipment specially designed for materials that cannot...

What is the use of sieve shaker in laboratory?

Laboratory Sieve Shaker Machine is an instrument used for material particle classification, particle size detection and analysis....

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap