Tuesday March-25 2025 14:59:04

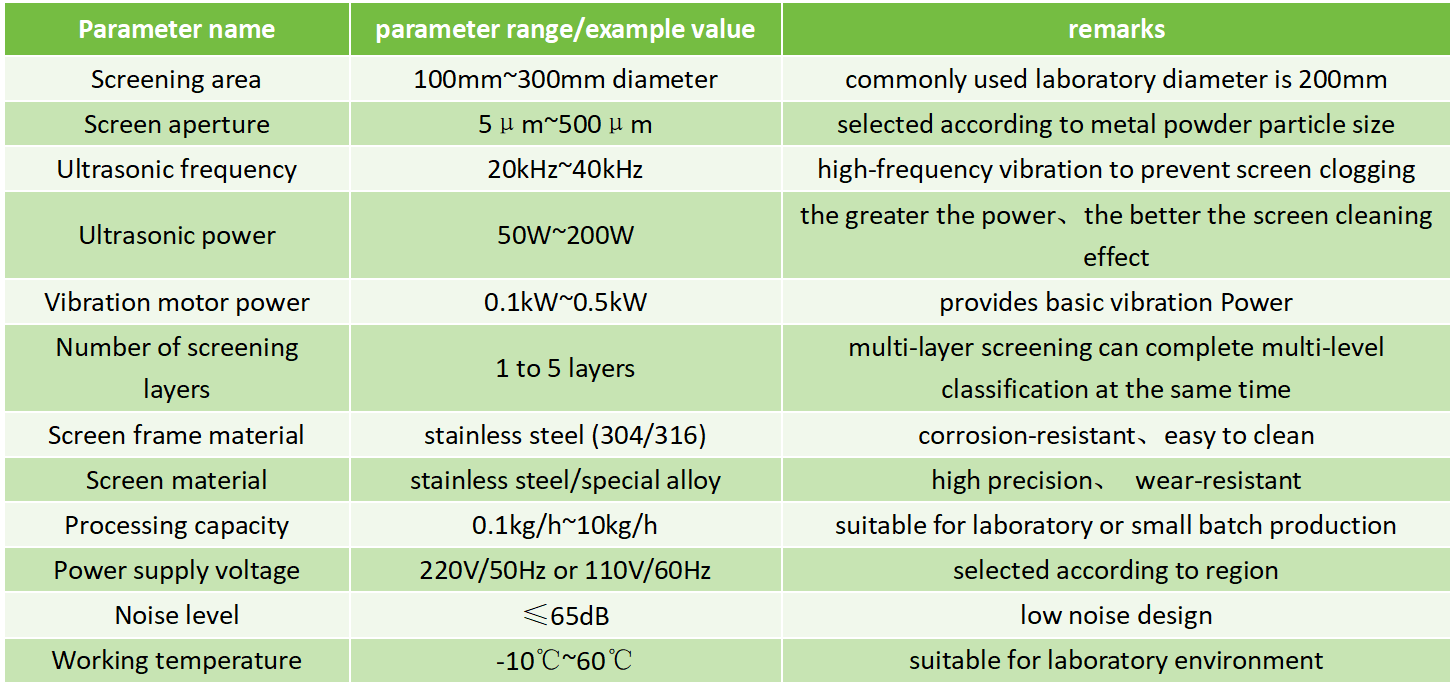

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch production to analyze and classify fine materials such as metal powder and alloy powder to evaluate the screening effect of metal powder and optimize the production process. Its core feature is to use the ultrasonic vibration system to make the screen produce high-frequency micro-vibration, thereby preventing the screen from being blocked and improving the screening efficiency and accuracy.

① Ultrasonic vibration: The ultrasonic generator generates a high-frequency electrical signal, which is converted into mechanical vibration through the transducer and transmitted to the screen. This high-frequency micro-vibration allows the metal powder to disperse quickly on the screen surface to prevent particles from clogging the screen.

② Vibration screening: The vibration motor provides basic vibration power to make the metal powder move on the screen surface, fine particles pass through the screen, and coarse particles remain on the screen surface.

③ Combined action: Ultrasonic vibration and mechanical vibration work together to significantly improve screening efficiency and accuracy.

Industrial ultrasonic metal powder test sieve is usually composed of stainless steel sieve frame, high-precision stainless steel or special alloy sieve mesh, ultrasonic generator, ultrasonic transducer, vibration motor, control system, etc.

1、Limitations of ultrasonic system: The transducer is the core component of the ultrasonic system, and its life is limited and needs to be replaced regularly. Ultrasonic waves will attenuate during transmission, affecting the screening effect. Long-term work may generate heat, affecting the stability and life of the equipment.

2、Limited adaptability to high-viscosity materials and nano-scale powders: For extremely high-viscosity metal powders, even ultrasonic vibration may not completely prevent clogging. Although ultrasonic waves help to screen ultrafine powders, there may still be agglomeration problems for nano-scale powders.

3、High cost: Industrial ultrasonic metal powder test sieve adds components such as ultrasonic generators and transducers, so the equipment cost is relatively high, and the maintenance and replacement costs are also high.

4、Not suitable for large-scale industrial production: Industrial ultrasonic metal powder test sieves are usually used in laboratories or small batches. Their processing capacity is relatively low and they are not suitable for large-scale industrial production.

Coarse mesh number: Generally, a lower mesh number is selected, such as 20 mesh to 60 mesh, which is suitable for preliminary removal of larger particles or impurities in metal powder.

Medium mesh number: For general metal powder screening, you can choose a medium mesh sieve, such as 80 mesh to 120 mesh. It is suitable for screening metal powder with medium particle size.

Fine mesh number: If fine screening is required to improve the fineness and purity of metal powder, you can choose a high mesh sieve, such as 150 mesh or more. It is suitable for fine screening of metal powder to remove tiny particles and fine impurities.

1. Powder material screening: Industrial ultrasonic metal powder test sieve can be used to finely screen metal powder, remove impurities, and improve the quality and purity of the product.

2. Powder coating production: Industrial ultrasonic metal powder test sieve can be used to screen powder materials such as pigments and fillers to ensure uniform product color and stable quality.

3. Metal ceramic material production: Industrial ultrasonic metal powder test sieve can be used to screen and mix metal and ceramic powders to obtain a uniform material mixture.

4. Metal 3D printing: Industrial ultrasonic metal powder test sieve can be used to screen metal powder, remove particle agglomeration, improve the uniformity of printed powder, and thus improve printing quality.

5. Powder metallurgy: Industrial ultrasonic metal powder test sieve can be used to classify and grade metal powder to meet different process requirements and improve product performance and quality.

6. Laboratory research: Industrial ultrasonic metal powder test sieve is also widely used in metal powder research and analysis in laboratories to evaluate the particle size distribution, shape and other characteristics of metal powders.

Industrial ultrasonic metal powder test sieve is a high-precision and high-efficiency screening equipment, especially suitable for screening and analysis of ultra-fine metal powders. Through reasonable selection and maintenance, the equipment can be ensured to operate stably for a long time and meet the needs of metal powder screening.

Ultrasonic test sieve for wheat flour

Ultrasonic test sieve for wheat flour is a device specially used for fine screening of wheat flour. It combines ultrasonic technology with traditional...

What Is An Electromagnetic Sieve Shaker?

Electromagnetic sieve shaker is a screening equipment used for testing and laboratory research. It is often used to screen and classify small batches...

Test sieve shaker is a laboratory equipment used for particle screening and classification, also known as laboratory shaker or laboratory vibrating...

Phosphate Test Sieve is an experimental tool used to screen different particle sizes in phosphate samples and detect the phosphate...

High precision subdivision test sieve

High precision subdivision test sieve is a device used in the laboratory to perform fine particle size analysis on granular and powdery...

Mar 25, 2025

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch productio...

Mar 25, 2025

Vitamin powder slapping screen

Vitamin powder slapping screen is a device used to sieve vitamin powder. It achieves sieving through ...

Mar 07, 2025

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis...

Mar 05, 2025

Ultrasonic test sieve for wheat flour

Ultrasonic test sieve for wheat flour is a special device that combines ultrasonic technology with tr...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap