Friday March-10 2023 09:19:44

Xinxiang Dahan Machinery is a manufacturer specializing in screening equipment, which has been producing screening equipment for more than 20 years. Among them, the stainless steel test sieve produced is also very strong and durable, and is often used for screening and testing in laboratories, but many users report that they will not use it after buying it, so, below. The staff of Dahan Technical Department will introduce the operation steps of Stainless Steel Test Sieves in detail.

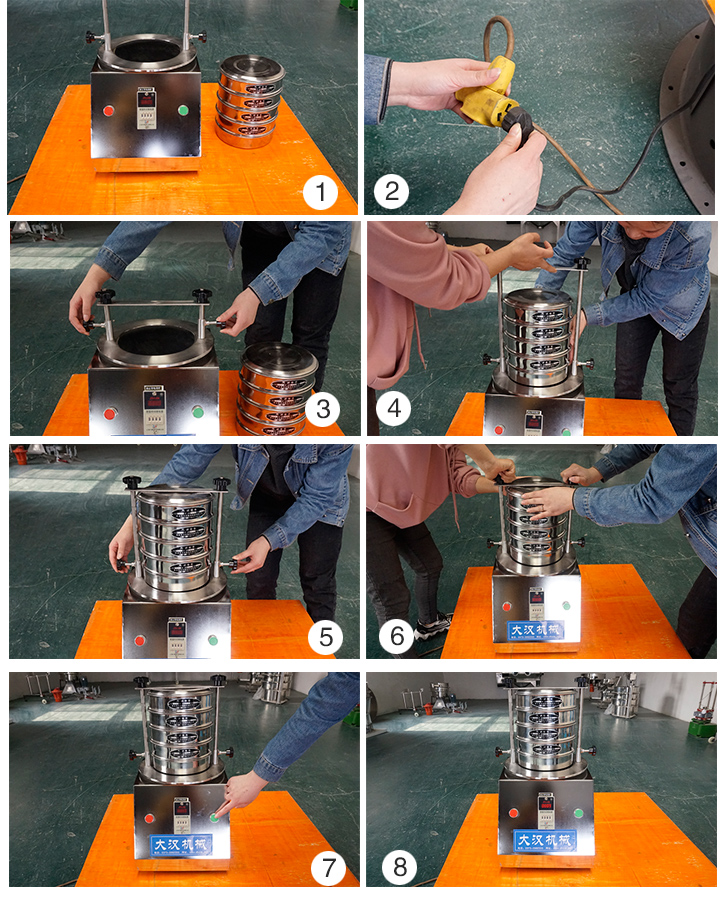

1. The direction of rotation of the Stainless Steel Test Sieves motor must be in the direction indicated by the arrow (three-phase motor) (because the cam is used to hit the ejector rod, the reverse direction will be pinned and cannot be rotated). Method for checking the direction of rotation of the motor: Lift the ejector rod before starting the machine, and then start the machine again. At this time, check the direction of rotation of the motor. If it is not correct, exchange the wire ends of two of the three phases and try again. Make sure the direction is correct before using it normally.

2. The equipment must be fixed before operation. The fixing is fixed with anchor screws, and the equipment can be fixed on the concrete floor with expansion screws.

3. Put the Stainless Steel Test Sieves into the equipment, and tighten the nuts on the top and both sides. The specific method is: first loosen the four lock nuts on the top and both sides of the Stainless Steel Test Sieves, so that the two uprights on both sides can fall freely and fall on the placed Stainless Steel Test Sieves, and then put the Lock the lock nut, and finally lock the two nuts on the top of the screen machine. Note: The nuts on the top and both sides must be locked

4. The equipment has a timing device, the user can adjust the use time, and it will automatically stop when it is turned on. The first two digits of the adjustment time are minutes, and the last two digits are seconds. Users can adjust the running time according to their needs.

5. The slapping height of the equipment is adjusted before leaving the factory. If necessary, the user can also loosen the fastening nut and adjust the thread of the ejector head to rise or fall to the appropriate level.

6. The upper and lower slides, oil nozzles, etc. should be refueled regularly.

After completing the above steps, turn on the green button on the front panel of Stainless Steel Test Sieves. After a period of sieving, the sieve machine will stop automatically when the timing is over, or you can press the red button to end the sieving. After sieving, you can sieve out the materials you need in multiple particle size segments at one time.

Mar 10, 2023

How to use Stainless Steel Test Sieves

Xinxiang Dahan Machinery is a manufacturer specializing in screening equipment, which has been produc...

Mar 03, 2023

What is the use of sieve shaker in laboratory

Laboratory Sieve Shaker Machine is an instrument used for material particle classification, particle ...

Mar 03, 2023

Nylon plastic for laboratory test sieves

Laboratory test sieves overview: Laboratory test sieves , also known as plastic nylon sieves, are lab...

Mar 03, 2023

What problems should I pay attention to when purchasing laboratory test sieves?

The introduction as follows: Laboratory test sieves of purchase notice: Tip 1: the purpose of screeni...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap