Thursday February-27 2025 10:18:47

High precision subdivision test sieve is a device used in the laboratory to perform fine particle size analysis on granular and powdery materials. It is widely used in many industries, especially in areas where strict control of material particle size is required.

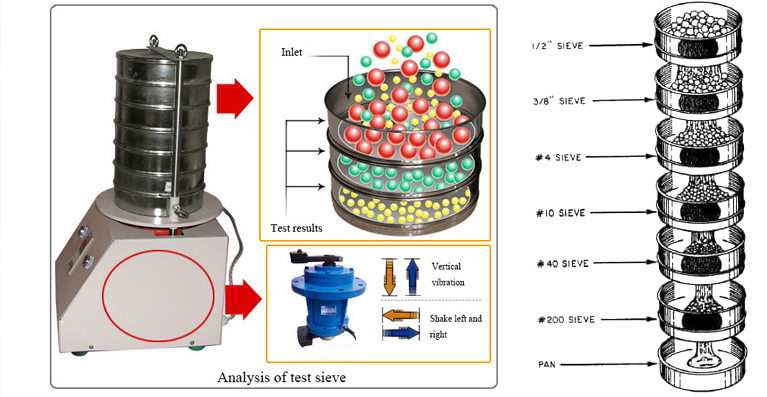

Place the material to be screened on the top screen. Start the high precision subdivision test sieve and the vibration system starts working. The material moves on the screen, and particles smaller than the mesh pass through the screen layer by layer. After the screening is completed, take out each layer of the screen and the collection plate, weigh them separately, and get the weight of the material at different particle size levels. According to the material weight and the screen aperture, calculate the particle size distribution of the material.

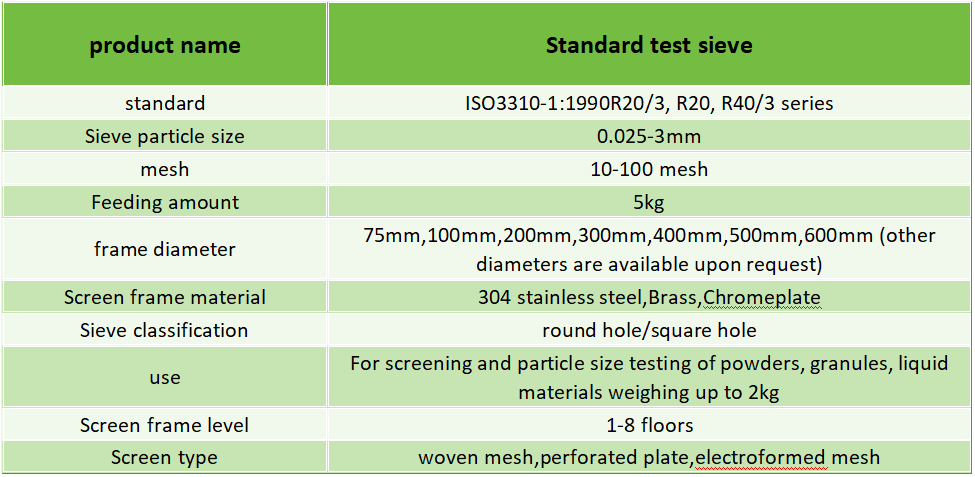

1. Multiple apertures: The aperture of the test sieve can be customized according to user needs. The mesh specifications are diverse, such as 2200 mesh, 22000 mesh, etc., and can even reach 3000μm to meet the needs of different particle size classification.

2. High precision screening: The aperture of high-end high precision test sieves can be as small as 3μm or even smaller, and the accuracy (error) can usually reach ±1μm. The accuracy index of some brands such as GULG high precision test sieves can reach ±0.5μm, which is particularly important for high precision application scenarios that require high consistency and high repeatability.

3. Accurate particle analysis: High precision subdivision test sieve can accurately analyze the particles and obtain more accurate particle size distribution data, which helps researchers and engineers to conduct accurate particle property research and process optimization.

High precision subdivision test sieve can be used to perform particle size analysis on particle samples, that is, to determine the size distribution range of the particles. This is crucial for many industries, such as medicine, food, chemical industry, materials science, etc. Through a high precision subdivision test sieve, particle samples can be screened according to different particle sizes, thereby achieving particle classification and separation.

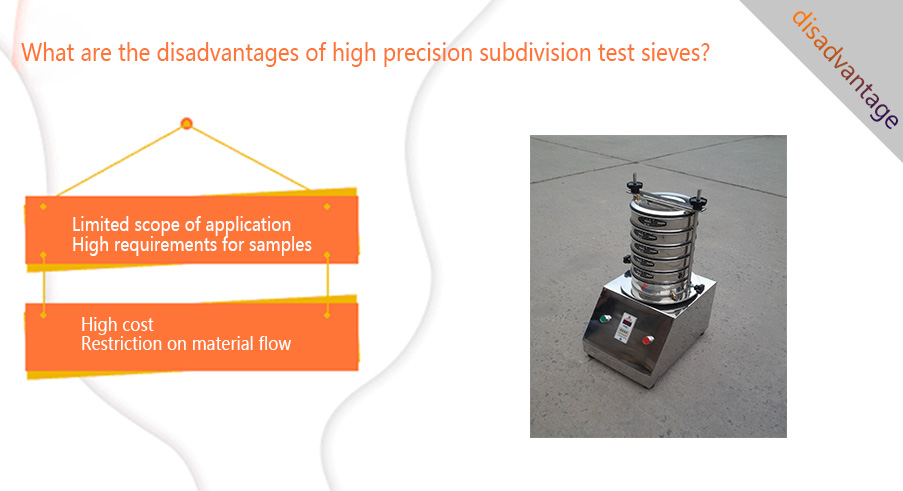

1. Limited scope of application: High precision subdivision test sieves are mainly suitable for dry, fluid powder materials, and have poor screening effects on wet and sticky materials. For fibrous, flaky or sticky materials, the screening effect may not be ideal. Although it is suitable for fine powder screening, the screening effect may not be ideal for extremely coarse or extremely fine particles.

2. High requirements for samples: The sample needs to be dry and free of agglomeration, otherwise it will affect the screening effect. The amount of sample screened by the high precision subdivision test sieve is limited each time, and too much or too little will affect the screening accuracy. Since the particles take longer to screen on the high precision subdivision test sieve, the screening speed is relatively slow, which may affect the efficiency of the experiment or production.

3. High cost: The manufacturing process of the high precision subdivision test sieve is complex and the material requirements are high, resulting in expensive equipment. The maintenance and replacement costs of components such as high precision screens and ultrasonic screen cleaning devices are high, so their cost is usually higher than that of ordinary test sieves. This may increase laboratory or production costs.

4. Restriction on material flow: In order to maintain high precision, it is necessary to control the material flow and material layer thickness to avoid material accumulation and uneven screening. High precision subdivision test sieve limits the processing capacity of the equipment. For materials that require large-scale screening, it may be necessary to increase the number of equipment or extend the screening time.

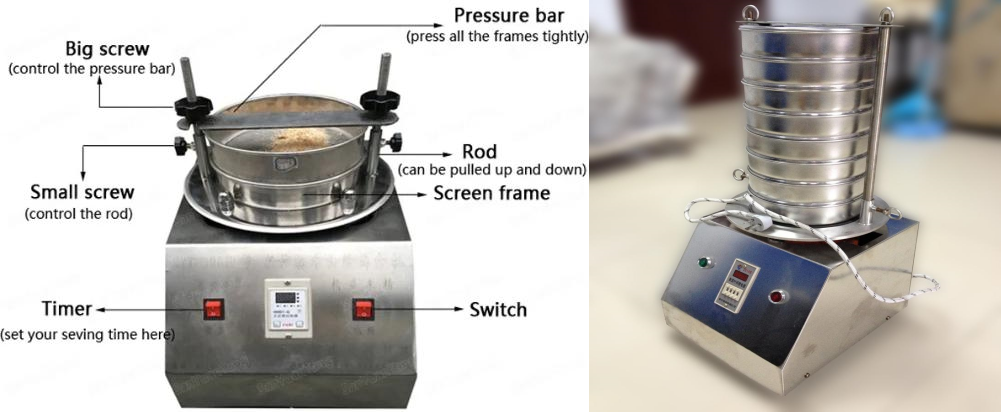

High precision subdivision test sieve is a device used for particle size analysis and screening experiments on aluminum powder or other granular materials. This test sieve usually consists of a sieve frame, a sieve, a vibrating device, a base, a collection container, an operating panel, etc. The sieve frame is the main part of the test sieve. A sieve is installed at the bottom of the sieve frame for screening particles. Screens of different specifications can be replaced as needed.

1、Pharmaceutical industry: The particle size of drug powder directly affects its solubility, absorption rate and bioavailability. High precision test sieves are used to accurately determine the particle size distribution of drug powder to ensure the quality and efficacy of drugs. For example, in the production of inhaled drugs, the particle size control of drug powder is particularly strict to ensure that the drug can effectively reach the lungs.

2、Food industry: The particle size of food raw materials such as flour, milk powder, and coffee powder affects their taste, solubility and processing performance. High precision test sieves are used to detect the particle size of food raw materials to ensure product quality and taste. The particle size of food additives affects their dispersibility and stability, and is used to control the particle size of food additives to ensure their uniform distribution in food.

3、Chemical industry: The particle size of chemical raw materials affects their reaction rate, solubility and product performance. High precision test sieves are used to analyze the particle size of chemical raw materials and optimize production processes. The particle size of fine chemical products such as pigments, coatings, and catalysts has an important influence on their performance, and can also be used to control the particle size of products to ensure the stability of product performance.

4、Material science: The particle size of nanomaterials has a significant effect on their physical and chemical properties. High precision test sieves are used to study the particle size distribution of nanomaterials and optimize material properties. The particle size of ceramic materials affects their sintering properties and mechanical strength, and is also used to control the particle size of ceramic powders and improve the quality of ceramic products.

High precision subdivision test sieve plays an important role in particle analysis, it effectively solves the problems in aluminum powder screening, improves screening efficiency and accuracy, and ensures operational safety and environmental cleanliness.

laboratory test sieve is also called standard sieve, test sieve, laboratory vibrating screen, sample sieve, inspection sieve, standard analysis sieve...

What Is An Electromagnetic Sieve Shaker?

Electromagnetic sieve shaker is a screening equipment used for testing and laboratory research. It is often used to screen and classify small batches...

Test sieve shaker is a laboratory equipment used for particle screening and classification, also known as laboratory shaker or laboratory vibrating...

Phosphate Test Sieve is an experimental tool used to screen different particle sizes in phosphate samples and detect the phosphate...

Aluminum powder laboratory test sieve

Aluminum powder laboratory test sieve is a device specially used for aluminum powder particle size analysis and classification. It...

Feb 27, 2025

High precision subdivision test sieve

High precision subdivision test sieve is a device used in the laboratory to perform fine particle siz...

Feb 27, 2025

What is a ceramic powder test sieve? Ceramic powder test sieve is a screening device used to accurate...

Feb 27, 2025

Metal powder test sieve is a device used to accurately measure the particle size distribution of meta...

Feb 24, 2025

Aluminum powder laboratory test sieve

Aluminum Powder Laboratory Test Sieve is a device used for aluminum powder particle size analysis and...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap