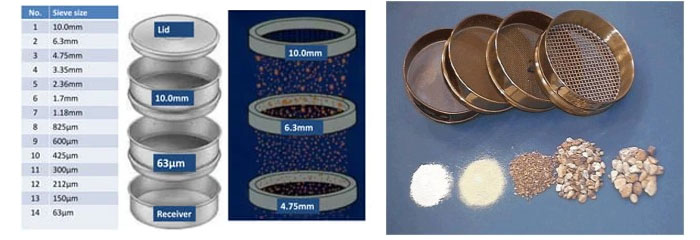

Experimental sieve is a tool used in the laboratory for particle size analysis and screening of powder or granular materials. It classifies materials according to particle size through screens of different apertures to obtain particle size distribution. Data provide important reference information for subsequent experimental research and production processes.

Diameter: 75mm,100mm,200mm,300mm,400mm Chat Now

Mesh size: 0.15-4.75mm

Mesh hole: 0.03-13mm

It is used for precision filtration in various industries such as metallurgy, wine industry, medicine, chemical industry, agriculture, food, grain, cement, coal, and geology.

1. Made of 304 stainless steel, non-magnetic, high temperature resistant, and can automatically shut down at a scheduled time to ensure test repeatability.

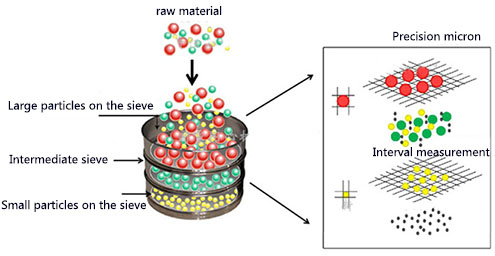

2. A kind of granular material can be precisely separated into 2-7 particle segments at the same time.

3. Provide a variety of specifications and mesh size options to meet different experimental needs and particle characteristics, allowing users to make choices based on specific experimental purposes.

| Quantity (set) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

Experimental Sieve is a sieving test instrument used in the laboratory, usually used for sieving powder, granules and other materials, and consists of two parts: a sieve frame and a sieve body. The size of the material is controlled and screened by the screen hole size of the screen frame, and its main screening power comes from the vibrating screen of the screen body.

Testing pharmaceutical powders: very fine powder No. 8 sieve (150 mesh) No. 9 sieve (200 mesh) no less than 95% of the powder.

It is a screening equipment used in laboratories or scientific research fields for screening, classifying or filtering solid particles or powders. Experimental sieves are usually used for experimental purposes such as particle analysis, particle size measurement, particle distribution analysis, etc.

Experimental Sieve is mainly used for the analysis and testing of the particle size of materials, and can be used to measure the size range and distribution of particles, as well as particle shape, density and other characteristics. Its application scope covers many fields such as chemical industry, mining, food, medicine, metallurgy, etc. The specific materials include aggregate, soil, cement, graphite powder, grain, sand, glass powder, etc.

Experimental sieves are often used in scientific research laboratories for particle analysis, particle size measurement, particle distribution analysis and other experimental research work. Experimental sieves are often used in the mining and metallurgical fields to screen and analyze ore particles to help improve the efficiency of ore beneficiation. In the chemical industry, experimental sieves are used for screening and classifying chemical product particles to ensure product quality and production efficiency.

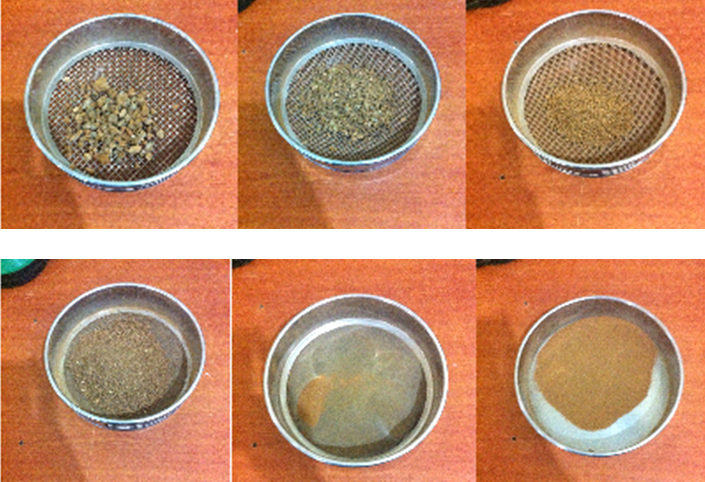

Spread the sample to be tested evenly on the experimental sieve, and make the particles in the sample pass through the sieve through vibration or sieving. Particles of different sizes will remain on the screens of different apertures or at the bottom of the screen box, thereby achieving particle size classification.

1.Prevent material clogging: through high-frequency vibration, the electrostatic interaction and surface tension between materials are destroyed. You can also choose appropriate screen materials, such as stainless steel, nylon, etc., to improve the wear resistance and corrosion resistance of the screen and reduce clogging phenomenon.

2.Conduct particle size analysis: Screens with different apertures can accurately classify materials according to particle size, obtain particle size distribution data, and provide a basis for subsequent experiments. The screening results have good repeatability, ensuring the reliability of the experimental data.

3.Reduce sample loss: The experimental sieve has a compact structural design. By stacking multiple layers of sieves, sample loss can be reduced, the recovery rate can be improved, and sample splashing and loss during the screening process can be effectively prevented.

4.Improve screening efficiency: Use efficient vibration methods, such as vibration motors, ultrasonic vibration, etc., and adjust the inclination angle of the screen to speed up the movement of materials and improve screening efficiency.

| Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) |

| 2 | 13 | 26 | 0.71 | 90 | 0.16 | 260 | 0.06 |

| 3 | 6.5 | 28 | 0.63 | 100 | 0.154 | 280 | 0.055 |

| 4 | 5 | 30 | 0.6 | 110 | 0.14 | 300 | 0.054 |

| 5 | 4 | 32 | 0.55 | 115 | 0.13 | 320 | 0.048 |

| 6 | 3.2 | 36 | 0.5 | 120 | 0.125 | 325 | 0.045 |

| 7 | 2.8 | 40 | 0.45 | 130 | 0.111 | 350 | 0.041 |

| 8 | 2.5 | 45 | 0.4 | 140 | 0.105 | 360 | 0.4 |

| 9 | 2.2 | 50 | 0.355 | 150 | 0.1 | 400 | 0.0385 |

| 10 | 2 | 55 | 0.315 | 160 | 0.098 | 500 | 0.03 |

| 12 | 1.6 | 60 | 0.3 | 180 | 0.09 | ||

| 14 | 1.43 | 65 | 0.25 | 190 | 0.08 | ||

| 16 | 1.25 | 70 | 0.22 | 200 | 0.075 | ||

| 18 | 1 | 75 | 0.2 | 220 | 0.07 | ||

| 20 | 0.9 | 80 | 0.18 | 240 | 0.065 | ||

| 24 | 0.8 | 85 | 0.17 | 250 | 0.063 |

1. Turn off the power of the test sieve

2. Loosen the iron buckles on the four corners to fix the standard sieve, remove the upper cover of the vibrating screen, and remove the two layers of screens.

3. Clean up the rest of the standard inspection sieve with a vacuum suction hose and a rag.

4. Use compressed air to clean the particles and powder from the sieve. If the particles and powder are stuck in the sieve and cannot come out, you can use a screwdriver to push out or tap the sieve.

5. Install the upper small hole screen - large hole screen - upper cover in order

6. The tools used when cleaning up the standard inspection sieve must be cleaned.

The sieve analysis test for sand is a method used to determine the particle size distribution and analysis of sand; it is commonly used for sand and gravel, and the visible sand is ...

Experimental Sieve is a commonly used experimental instrument in scientific research, which plays an important role in the process of material analysis and sieving. Experimental Sie...

Sand sieve analysis is a technique used in civil engineering and geotechnical engineering to determine the particle size distribution of a sample of sand. It involves separating the...

Introduction of Perforated Plate Sieve

A Perforated Plate Sieve is a sieve commonly used for filtering and sifting materials. It has the characteristics of a perforated plate inner diameter of 3mm to 5mm and a plate thic...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap