Electromagnetic sieve shaker is a high-precision sieving instrument, which uses electromagnetic drive and three-dimensional movement, and can sieve powder and liquid, and can sieve to 20um (635 mesh). The negative pressure device designed by our company can dry and screen materials as fine as 5um. Solve the clogging problem of ultra-fine powder dry sieve.

$650.00 - $1,200.00/ Sets Chat Now

Screening accuracy: 5μm

Diameter of screen frame: 75mm/100mm/200mm/300mm

Vibration frequency: 3000 times/min

Can put screen: 1-8 layers

1. Electromagnetic Vibration + Triple Vibration Action: Vertical, Lateral and Rotation

2. Digital microprocessor control panel adjustable: timer 0-99 minutes; continuous or intermittent vibration action; pause between vibrations (for fines screening)

3. The control panel can be fixed to the wall or placed on the workbench

Port:Any port in China (Mainland)or as you need.

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

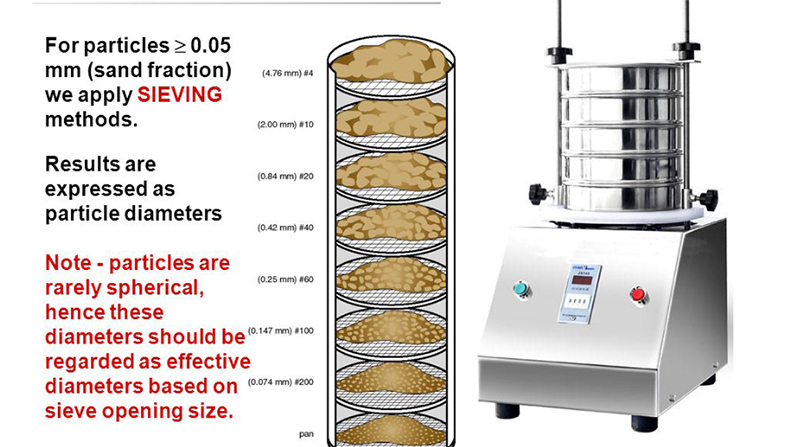

Electromagnetic Sieve Shaker is also called electromagnetic vibrating screen. It adopts electromagnetic drive and three-dimensional movement. It is suitable for dry and wet particle separation and particle size testing. It can sieve to 20um (635 mesh), add a negative pressure device, and can sieve materials to 5um. Solved the problem of ultra-fine powder difficult to dry sieve. The vibration frequency of the Electromagnetic sieve shaker can reach 3000 times per minute. Because the screen surface can vibrate up and down at high frequency, the material can be thrown out from the mesh, and the material is not easy to stick to the mesh, which improves the screening efficiency of fine materials; The 8-layer test sieve (including the sieve bottom) can precisely separate a granular material into 2-7 particle size segments at the same time.

Sieving pulverized coal: an experiment to measure yield and quality characteristics of coal samples smaller than 0.5mm

Testing quartz sand: diameter 200mmElectromagnetic Sieve Shaker Quartz sand is tested for screening different grades

Testing pharmaceutical powders: use 304 stainless steel Electromagnetic Sieve Shaker to test 80 mesh traditional Chinese medicine powder

1. Screening particles: Electromagnetic Sieve Shaker uses the vibration force generated by the electromagnetic vibrator to vibrate the particles on the screen, thereby realizing the screening and grading of particles.

2. Preventing blockage: The vibration effect of Electromagnetic Sieve Shaker can prevent particles from clogging on the screen and maintain the continuity and stability of the screening process.

3. Precise control: The equipment is equipped with a precise control system that can adjust the vibration frequency and amplitude of the electromagnetic vibrator to achieve precise control of the screening process.

4. Wide range of applications: Electromagnetic Sieve Shaker is suitable for the screening of various granular materials and can be widely used in food processing, chemical, pharmaceutical and other industries.

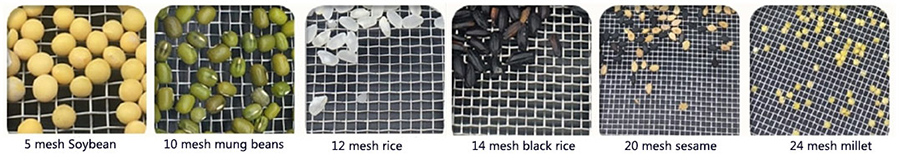

Electromagnetic sieve shaker is used for particle separation and detection of material particle size distribution, and can be used for wet and dry screening up to 5 microns; Mainly used in soil research and laboratory and industrial fields, specific materials are: flour, aggregates, coal, pigments, soap, cement, medicinal powder, feed, sesame, abrasive, etc.

Electromagnetic sieve shaker screens are divided into metal woven screens, metal perforated screens, and electroformed screens.

Electromagnetic sieve shaker frame materials are available in stainless steel, brass and nylon.

| Test sieve pictures |  |

|

|

| Type | Wire braided mesh test sieve | Metal perforated plate test sieve | Electroformed sieve |

| Test sieve surface |  |

|

|

| Screen frame diameter | 8 size, 12 size 75mm,200mm,300mm |

8 size, 12 size 200mm,300mm |

75mm,200mm |

1. Electromagnetic drive + three-dimensional movement, the vibration frequency is 3000 times/min, which improves the penetration rate of the screen and avoids sticking to the screen.

2. Suitable for dry and wet sieving, it can quickly separate particles and measure particle size distribution.

3. It can measure samples weighing up to 2kg in the range of 120mm to 20μm, and add a negative pressure device, which can dry and sieve to 5μm, which solves the problem of dry sieving of ultrafine powder.

4. The sieve machine can be placed with 8 layers of test sieves (including the bottom of the sieve), which can precisely separate a granular material into 2-7 particle segments at the same time.

5. Equipped with time relay control, it can automatically shut down at regular intervals to ensure the repeatability of the test, and the platform operation does not need to be fixed.

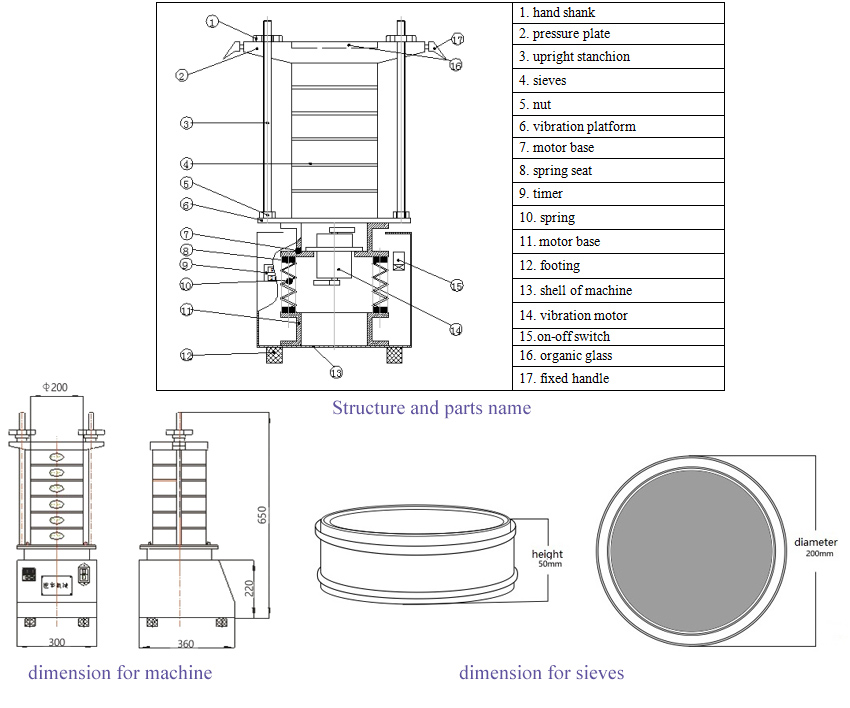

Electromagnetic sieve shaker structure mainly includes: bakelite handle, pressure plate, pressure rod, pressure rod lock nut, screen cover, screen frame, bottom frame, tray, time relay, start indication, start button, stop indication, stop button, casing, etc.

The Electromagnetic sieve shaker uses an electromagnetic vibrator as the vibration source. The vibration of the electromagnetic vibrator drives the vibration of the base of the sieve machine, and then passes through the base to a set of standard test sieves arranged from coarse to fine on the base, so that the test sieve vibrates up and down at high frequency. The lower vibrating motor (or reciprocating mechanism) spreads the material. The material vibrates on the screen surface of the standard test sieve, so that the material particles smaller than the mesh size of the test sieve are sieved into the lower test sieve. The particle size composition of the material was isolated and determined.

The below table shows the detailed data of different models of electromagnetic sieve shaker for your reference.

| serial number | name | Numerical value | unit |

| 1 | Can put sieve | 1~8 | layer |

| 2 | Screen diameter | φ200/φ100/φ75 | mm |

| 3 | Sieve particle size | 0.025~3 | mm |

| 4 | noise | less than 50 | dB |

| 5 | amplitude | 0~3 (stepless adjustment) | mm |

| 6 | electromagnetic vibration frequency | 3000 | times/min |

| 7 | Motor vibration frequency | 1400 | times/min |

| 8 | Dimensions | 435*350*720 | length*width*height |

| 9 | power supply | 220;50 | V;HZ |

| 10 | Total Weight | 55 | KG |

| Electromagnetic Sieve Shaker | Mechanical Sieve Shaker | |

| application | Powder/liquid sieving, can dry sieve 5um materials, special equipment for ultrafine powder materials that are difficult to dry sieve | For particle size separation and classification of powders/granules/suspensions |

| price | $650.00 - $1,200.00/ Sets | $20.00-$3,680.00/Set |

| Screening accuracy | 5μm | 0.025-3mm |

| model | 75mm/100mm/200mm | 75mm/100mm/200mm/300mm/400mm/500mm |

| vibration frequency | 3000 times/min | 1500 times/min |

Dahan Electromagnetic sieve shaker provides electromagnetic sieving machine, stainless steel Electromagnetic sieve shaker, ultrasonic Electromagnetic sieve shaker, metal woven mesh Electromagnetic sieve shaker, metal punching plate Electromagnetic sieve shaker and other equipment. 1-7 floors, test materials and use locations can be customized according to customer requirements.

1. If you need to adjust the vibration amplitude, you can adjust the potentiometer knob to get different amplitudes. If you adjust the material spreading range, please adjust the motor eccentric block. The method is to adjust the length of M8 bolts or additional screws on the excitation block on the motor. Different excitation forces can be obtained. Generally not adjusted.

2. Adjust the time according to the screening needs. The first two digits of the time relay on the left side of the front panel of the standard vibrating screen machine are minutes and the last two digits are seconds. Timing time can be adjusted as needed within 0-99 minutes and 59 seconds.

3. For the test sieve used in the standard vibrating screen machine, the lower layer is lowered (non-porous sieve), and the sieve cover is placed on the top. The middle of the sieve bottom and sieve cover can be put into 1-7 layers of test sieves according to the requirements of the sieving granularity section, from top to bottom, from coarse to fine. Floor.

4. Put the test sieve into the equipment and lock the nuts on the top and both sides. The specific method is: first loosen the four locking nuts on the top and both sides of the standard vibrating screen, so that the two columns on both sides can fall freely on the test screen that has been placed, and then lock the two sides of the screen first. Tighten the nut, and finally lock the two nuts on the top of the screen machine. Note: The nuts on the top and both sides must be tightened. The tightening is through the two nuts on the top of the screen machine when the two sides of the top are loosened to a low level, and then the top nuts are tightened after pressing on both sides.

5. After completing the above steps, turn on the green button on the right side of the front panel of the standard vibrating screen machine. After a period of time for screening, when the time is over, the screen machine will automatically stop, or you can press the red button to end the screening. At the end of the screening, you can screen out the materials with multiple particle size segments you need at one time.

Screening accuracy: 5μm

Price: $450.00 - $1,000.00/ Sets

Measuring range: 20µm - 125mm

Price: $520.00/Sets

Laboratory Sieve Shaker Machine

Measuring range: 20µm-125mm

Price: $600.00 - $980.00/Set

Screening particle size: 0.025-3mm

Price: $538.00 - $925.00/Set

What are the uses of electromagnetic sieve shaker

Electromagnetic Sieve Shaker adopts electromagnetic drive, three-dimensional movement, and can sieve to 20 microns (635 mesh). This article will introduce the use of Electromagnetic...

Electromagnetic Sieve Shaker Principle

Electromagnetic Sieve Shaker is a laboratory test sieve designed for ultrafine powder screening and detection based on the original ordinary test sieve. It has higher screening accu...

Electromagnetic Sieve Shaker Price

Electromagnetic Sieve Shaker Price: $650.00 - $1,200.00/Sets. The specific price is related to the material, model and manufacturer....

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap