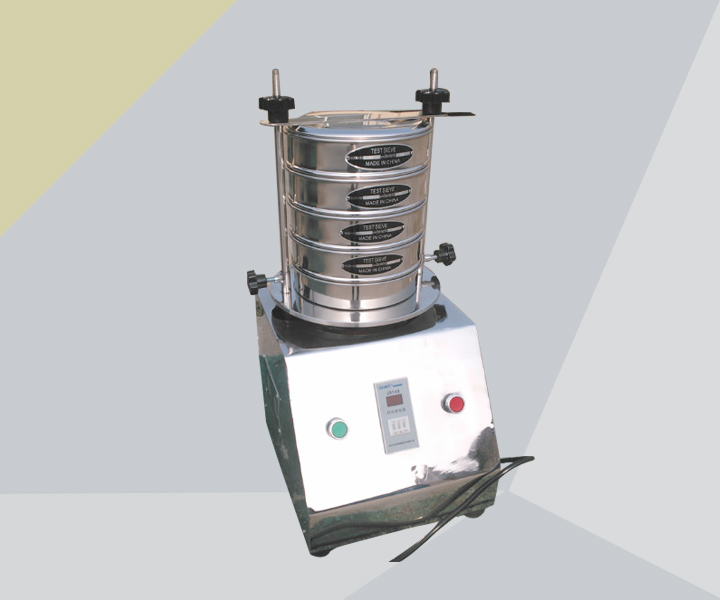

Electric Sieve, also called Electric sieve shaker, adopts electromagnetic drive + three-dimensional motion, can dry and wet sieve, can quickly separate particles and measure particle size distribution.

$200.00-$520.00/SetsChat Now

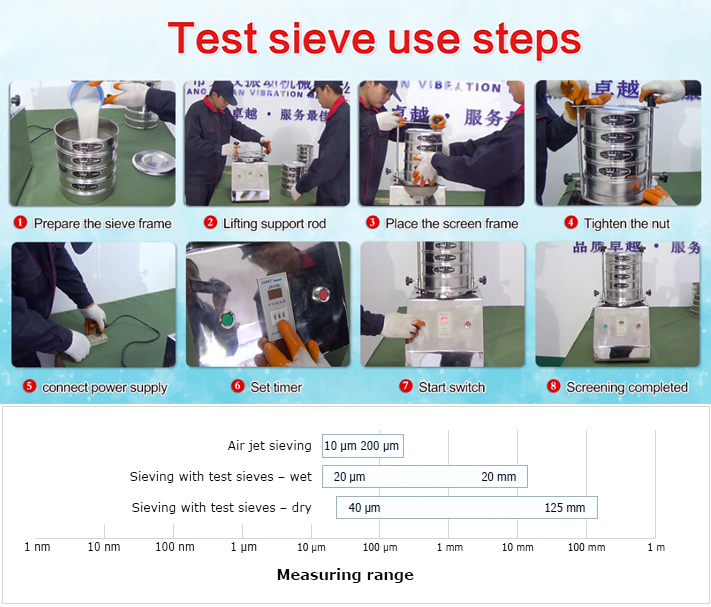

Test range: 20µm-125mm

Diameter: 75mm, 100mm, 200mm, 300mm, 400mm, 500mm

Sieve Height: 3.3" (85mm)

Material reference: flour 30-50 mesh; cake 40 mesh; whole grain flour 20-50 mesh; traditional Chinese medicine powder 50-80 mesh; millet 24 mesh; cellulose powder 80-100 mesh.

Electromagnetic drive + three-dimensional motion, high screening accuracy, can screen materials within 125 mm to 20 μm.

Can sieve samples up to 2 kg

1-8 layers of sieve frame are optional, which can separate 2-7 kinds of particle segments

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

Electric sieve is a tool for particle size classification and particle size detection of material particles. It is driven by electromagnetic force and has a vibration frequency of 1440-3000r/min. It can quickly and effectively sieve powder particles and filter fluids. The electromagnetically driven vibrating sieve system converts the vibration of the sieve group into adjustable vertical vibration, which can measure samples weighing up to 2kg in the range of 120mm to 20μm, which is an ideal equipment for laboratory sieving.

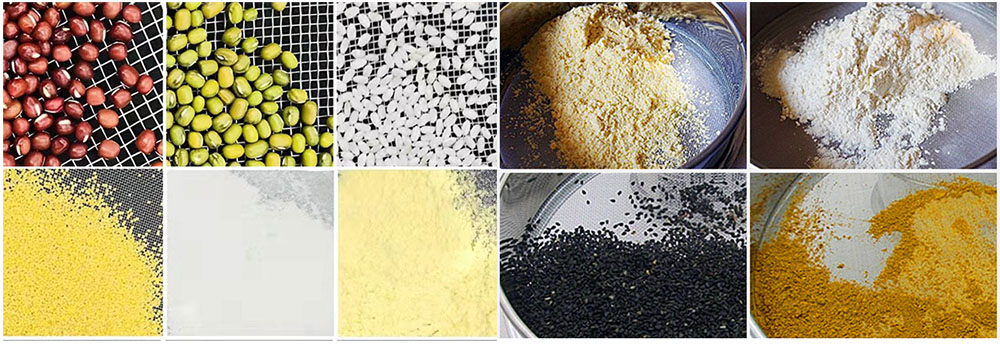

Electric sieve can be used for the inspection of solid and powder, slurry and other materials in scientific research units, laboratories, production control and other departments of food, medicine, chemical industry, abrasives, pigments, mining, metallurgy, geology, ceramics, national radio and other industries Sieving, grading, particle size analysis, debris content analysis, etc.

The specific materials and mesh sizes are used for reference as follows:

Grain granules: black bean 5 mesh, red bean 5 mesh, soybean 6 mesh, barley 8 mesh, mung bean 10 mesh, buckwheat 12 mesh, rice 12-14 mesh, black rice 14 mesh, brown rice 14 mesh, oat kernel 14 mesh, cassia seed 16 Mesh, broken corn 16 mesh, sesame 24 mesh, millet 24 mesh

Powder categories: fried chicken powder 10-30 mesh, corn flour 30 mesh, almond flour 30-40 mesh, whole grains 30-40 mesh, traditional Chinese medicine powder 40-60 mesh, flour 50-60 mesh, intestinal powder 60 mesh, oral 60-80 mesh, Panax notoginseng powder 80-100 mesh, fine traditional Chinese medicine mask 100-120 mesh, pearl powder 120-180 mesh, pine pollen 80-120 mesh, coffee powder 100-120 mesh, dusting powder 100-140 mesh, 3D Print 300-500 mesh

Liquids: filter soy milk, honey 60-120 mesh, filter medicine residue, soup residue, tea water 80-150 mesh

Others: 6 mesh of Chinese prickly ash, 8-10 mesh of pepper seeds, 12 mesh of Tenebrio molitor spawning sieve, 30 mesh of insect excrement sieve, 30-40 mesh of cat litter, 50 mesh of butterfly noodles, 80-120 mesh of sand painting, edible oil, Mechanical oil residue 150-200 mesh,

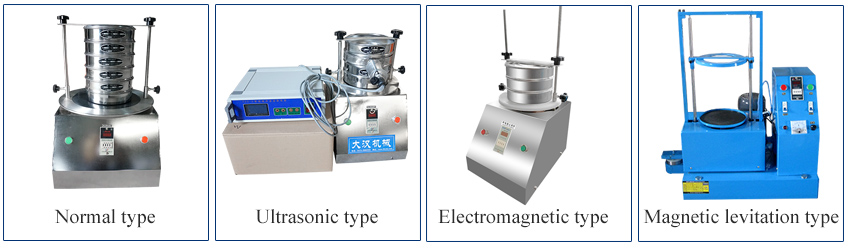

Ordinary Electric Sieve: There are 300 and 400 types, the machine is equipped with sieve frames of different diameters, and the matching sieve frame mesh number is 8-400 mesh.

Ultrasonic Electric Sieve: An ultrasonic system is installed on the basis of the ordinary sieve machine, which can sieve fine powder materials smaller than 300μm with strong adsorption, easy clumping, high static electricity, high density and light specific gravity, and solve the problem of fine powder blocking.

Electromagnetic Electric Sieve: It adopts electromagnetic driven sieve machine, the sieve surface adopts high frequency up and down vibration, the material does reciprocating suspension motion, the material sticks to the net, and there is no residue. With a measurement range of 5μm-63mm, it is ideal for quantitative particle size analysis of various solids and suspensions by dry or wet sieving or micro-precision sieving using woven mesh test sieves.

Magnetic levitation Electric Sieve: Using magnetic levitation technology, mechanical material movement + high-frequency electromagnetic vibration, with three movement modes of reciprocating, swinging, and vibration, the material is fast, and it is not easy to block the screen surface, and the screen is as fine as 5 microns.

Electromagnetic drive, vibration frequency 3000 times/min, improve screen penetration rate, avoid material sticking to the net

Suitable for dry and wet sieving

It can be sieved to 20μm (635 mesh), and the negative pressure device designed by our company is added, which can dry sieve and screen materials of 5μm, which solves the problem of dry sieving of ultra-fine powder.

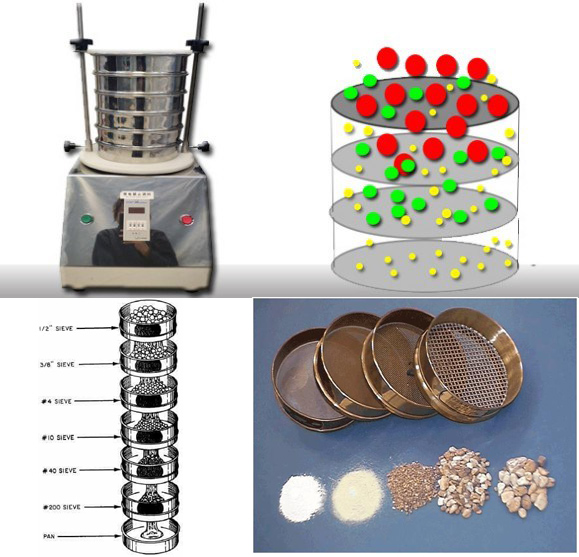

The sieve machine can be equipped with 8 layers of test sieves (including the bottom of the sieve), which can precisely separate 2-7 particle size segments from one kind of granular material at the same time.

0-99 minutes timer, automatic shutdown can be scheduled to ensure the repeatability of the experiment and reliable data.

Electric sieve is a laboratory test sieve designed for the screening and testing of ultrafine powder on the basis of the original ordinary test sieve. It uses an electromagnetic vibrator as the vibration source. The bottom seat is transmitted to a set of standard test sieves arranged from coarse to fine on the base, which vibrates up and down at a high frequency, while the vibration motor (or reciprocating mechanism) installed in the lower part spreads the material. The material vibrates on the screen surface of the standard test sieve, so that the material particles smaller than the mesh size are sieved into the lower test sieve, and the layers are screened so that only materials of the same particle size are left in each layer of the test sieve, and the separation of different particle sizes is achieved. Determine the particle size composition of this material.

The following is the basic configuration of the electric sieve, for user reference only.

| Serial number | name | Unit | Value | |

| 1 | Sieve surface diameter | mm | Φ200/100/75 | |

| 2 | Number of layers of screen surface | Layer | 1—8 | |

| 3 | Number of swings | Times/Minutes | 290 | |

| 4 | Round trip distance | mm | 25 | |

| 5 | Number of round trips | Times/Minutes | 290 | |

| 6 | Number of vibrations | Times/Minutes | 3000 | |

| 7 | Amplitude | mm | 0——3 | |

| 8 | Motor | Power | KW | 0.37 |

| Speed | Revolutions/Minutes | 1400 | ||

| 9 | Dimensions | mm | 660X470X800 | |

| 10 | Weight of the whole machine | KG | 105 | |

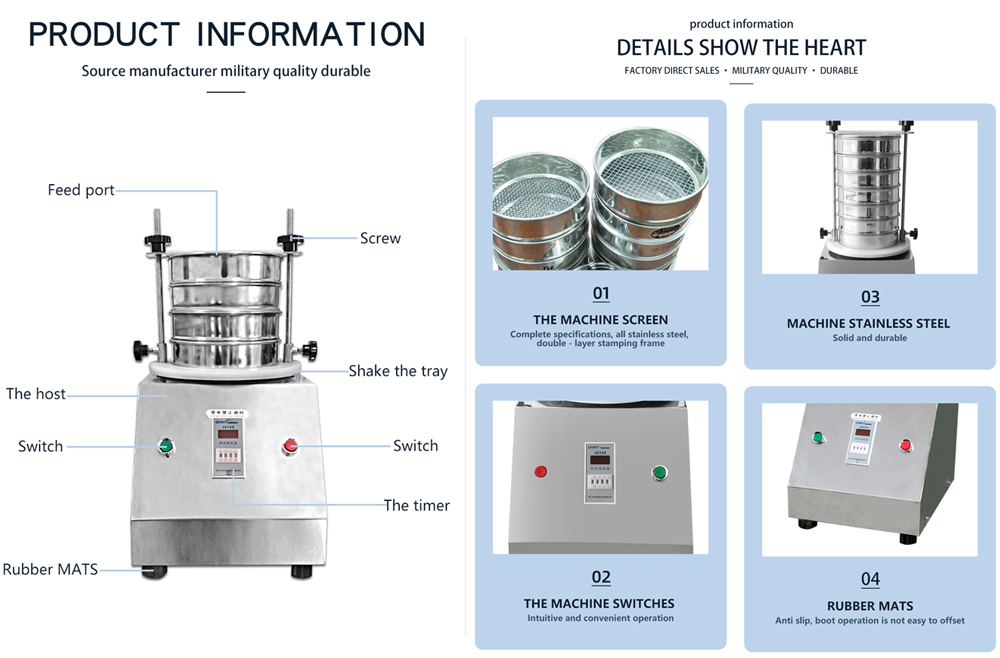

Electric sieve is composed of fixed brass nut, pressure plate, screen cover, screen frame, middle screen frame, screen bottom, isometric adjustment rod, etc. All parts are made of SUS304 stainless steel and are matched with each other. Flexible and interchangeable.

1. The Electric sieve should be placed horizontally, and check whether the power connection is correct, check the vibration part of the sieve, and ensure that it does not come into contact with other objects;

2. According to the properties and size of the material, select the appropriate screen frame;

3. According to the size of the aperture of the screen frame, stack them in order from small to large and from bottom to top;

4. Put the material into the screen frame at the upper end, then adjust the height of the adjusting rod according to the total height of the screen frame, and then position and press the screen frame;

5. Use the timer accurately, after setting the running time, start the Electric sieve to start working;

6. After the Electric sieve stops working, release the lock nut, remove the pressing plate and carefully remove the sieve frame;

7. Cut off the power.

Screening accuracy: 5μm

Price: $650.00 - $1,200.00/Sets

Screening accuracy: 20µm-25mm

Price: $600.00/Set

Laboratory Sieve Shaker Machine

Measuring range: 20µm-125mm

Price: $600.00 - $980.00/Set

Mesh sizes: 20 µm - 40 mm

Price: $523.00 - $936.00/Sets

Electric sieve shaker price: $200.00-$680.00/unit.The specific price is related to material, model, customization, etc....

Conversion table between classification of standard test sieve and mesh aperture

standard test sieve is mainly used in various laboratories, laboratories, research institutes, inspection rooms, etc., for random inspection, inspection and testing of small samples...

Application of wet sieve test screening material

In many cases, wet sieve test sieving, despite the inconveniences that come with it, has clear advantages over dry sieving. For example, the material to be tested may have been susp...

What problems should I pay attention to when purchasing laboratory test sieves?

The introduction as follows: Laboratory test sieves of purchase notice: Tip 1: the purpose of screening: If you are purchasing for the laboratory, you must require exquisite appeara...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap