Thursday February-27 2025 11:11:01

Drug test sieve is a screening device specially used in drug research and production. It is mainly used for particle size analysis, grading and impurity removal of drug raw materials, intermediates and finished products to ensure the quality and efficacy of drugs. It is widely used in pharmaceutical, chemical, food and other industries.

Drug test sieves are basically the same as ordinary screening equipment, both of which use the aperture size of the sieve to separate materials of different particle sizes. The difference is that drug test sieves usually have higher precision and stricter quality control standards to meet the special requirements of drug production.

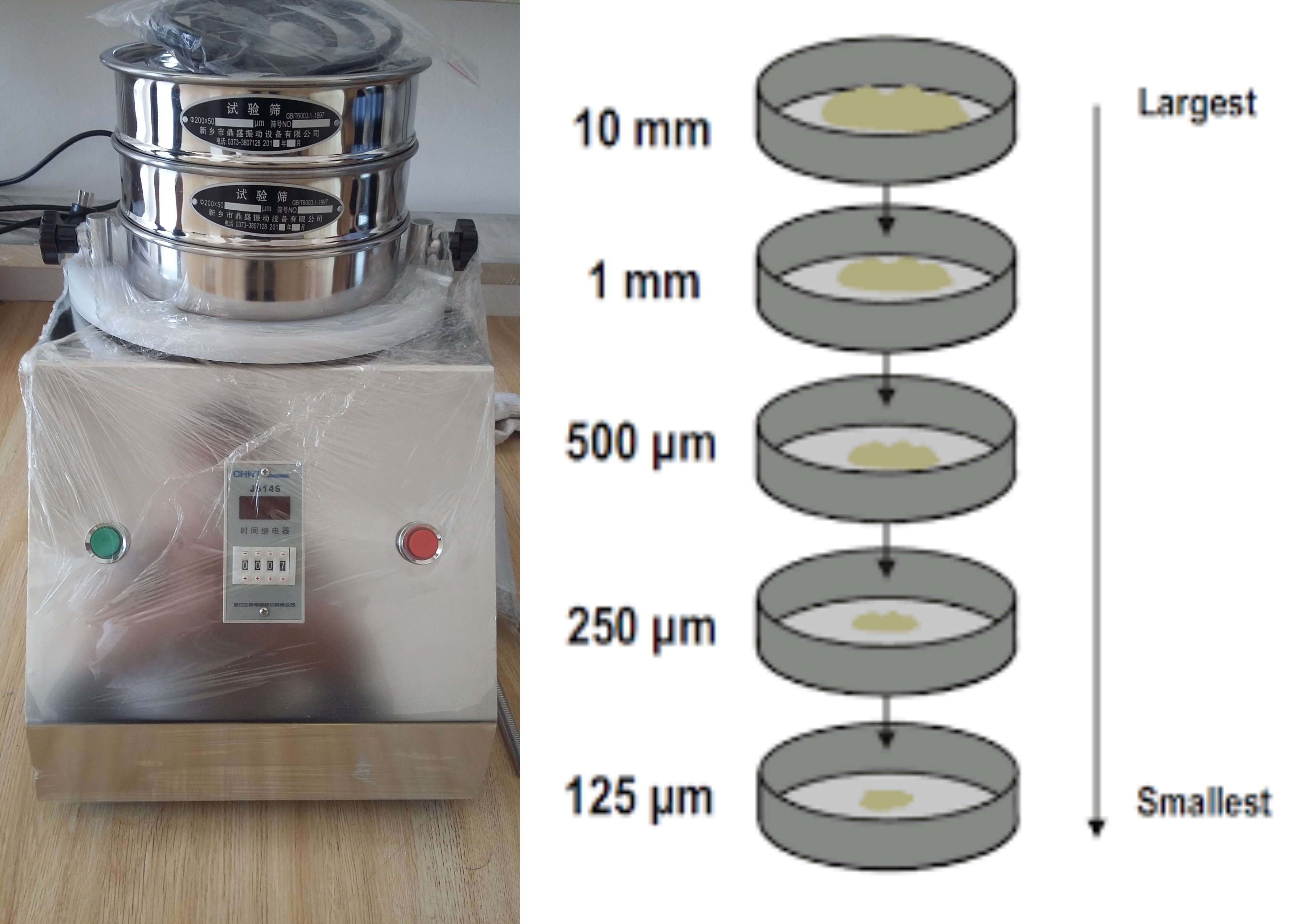

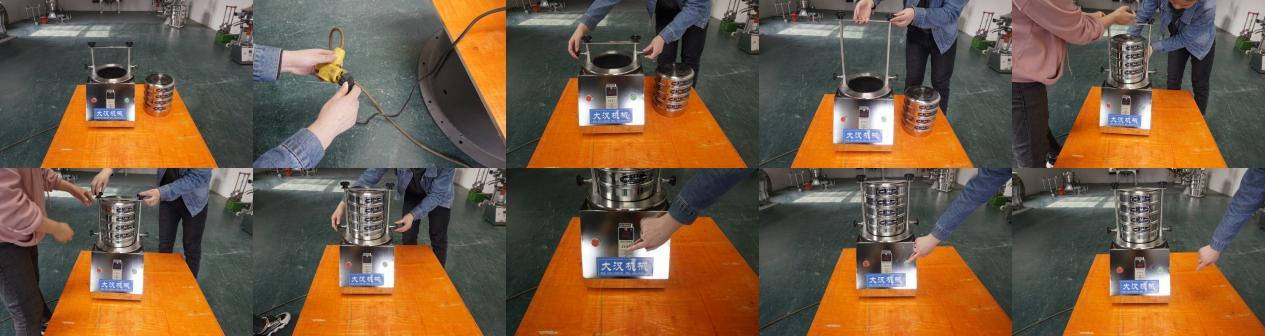

1. Preparation: Select the sieve of appropriate size and stack them in order from large to small mesh. Prepare the receiving tray and lid to ensure that the sieve group is firmly installed.

2. Sample processing: Take a representative drug sample, dry it and weigh it. If the sample is agglomerated, it needs to be crushed or dispersed in advance.

3. Sieving operation: Pour the sample into the top sieve. Gently shake the sieve group to allow the drug particles to pass through the sieve holes. Use a vibrating sieve machine and set the time (usually 5-15 minutes) for automatic sieving.

4. Collection and weighing: After the sieving is completed, remove the sieves layer by layer and collect the drug particles on each layer of the sieve. Use a balance to weigh the mass of each layer of drug particles and record the data.

5. Data analysis: Calculate the mass percentage of each particle size interval. Draw a sieving curve and analyze the drug particle size distribution.

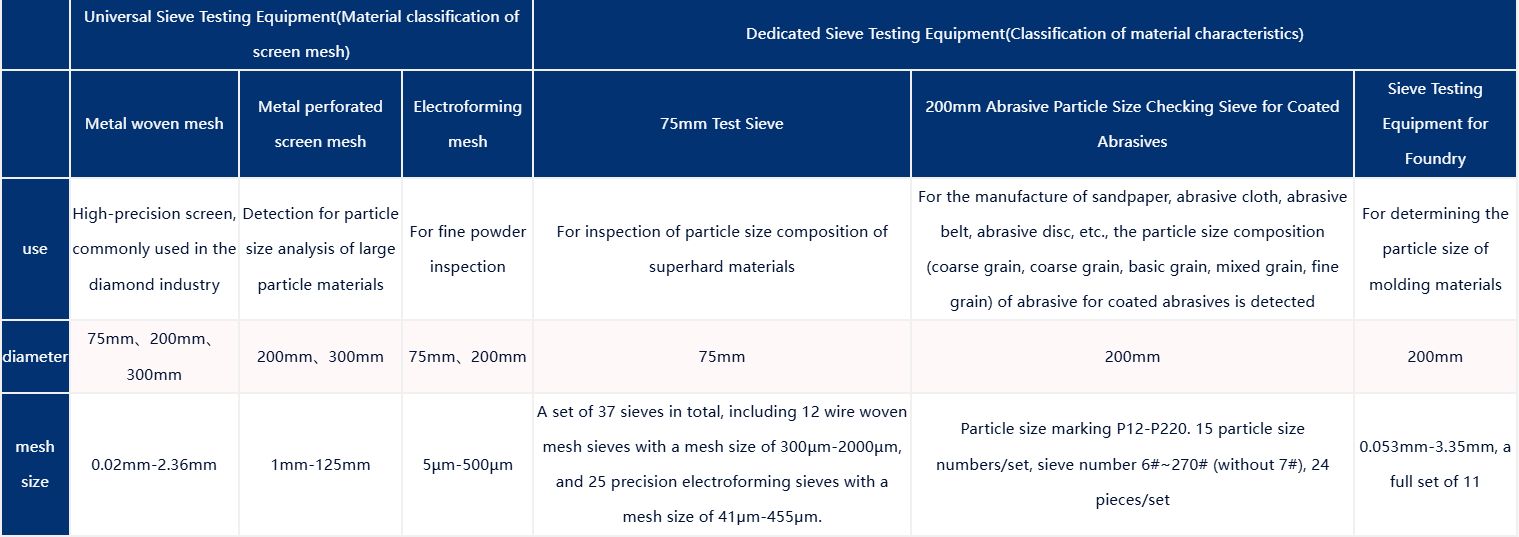

Drug test sieve is mainly composed of three parts: the screen frame, the screen mesh and the chassis.

Screen frame: usually made of stainless steel, with good corrosion resistance and wear resistance. The diameter and height of the screen frame are selected according to needs.

Screen mesh: The screen mesh is the core component of screening and is woven from metal wire or nylon wire. The aperture size of the screen mesh is selected according to needs, and high precision is required.

Chassis: used to collect materials passing through the screen mesh.

1. Drug raw material screening: In the drug research and development stage, researchers need to screen various drug raw materials and select suitable raw materials for the preparation of new drugs. Drug test sieves can help screen out particles that meet the requirements and ensure the quality and purity of the raw materials.

2. Intermediate screening: In the drug production process, intermediates need to be screened to remove impurities or unnecessary particles to ensure the purity and stability of intermediates.

3. Finished drug quality control: In the final stage of drug production, finished drugs need to be quality controlled, including parameters such as particle size and shape. Drug test sieves can help test the particle characteristics of finished drugs and ensure that the product meets the specified quality standards.

4. Solvent screening: In drug production, solvents often need to be screened to remove impurities or solid particles, ensure the purity of the solvent, and avoid affecting the quality of the drug.

Screen selection: Choose the appropriate screen size according to the drug particle size range. The screen material needs to be wear-resistant and corrosion-resistant (such as stainless steel).

Sample volume control: The sample volume should not be too large to avoid affecting the screening efficiency. Too little sample volume may result in unrepresentative data.

Screening time: The screening time must be sufficient to ensure that the drug particles are fully graded. Too short may result in incomplete screening, and too long may cause particle damage.

Screen cleaning: The screen needs to be thoroughly cleaned before and after screening to prevent blockage or cross contamination.

Repeated testing: To improve accuracy, it is recommended to perform multiple tests and take the average value.

Drug test sieve is an efficient and multifunctional screening equipment, which is widely used in pharmaceutical, chemical, food and other industries. Through reasonable selection, correct use and regular maintenance, its performance advantages can be fully utilized to meet the screening needs of different materials.

laboratory test sieve is also called standard sieve, test sieve, laboratory vibrating screen, sample sieve, inspection sieve, standard analysis sieve...

What Is An Electromagnetic Sieve Shaker?

Electromagnetic sieve shaker is a screening equipment used for testing and laboratory research. It is often used to screen and classify small batches...

Test sieve shaker is a laboratory equipment used for particle screening and classification, also known as laboratory shaker or laboratory vibrating...

Phosphate Test Sieve is an experimental tool used to screen different particle sizes in phosphate samples and detect the phosphate...

304 stainless steel soil test sieve

304 stainless steel soil test sieve is a professional screening equipment specially used for soil particle size analysis, particle...

Feb 27, 2025

Drug test sieve is a screening device specially used in drug research and production. It is mainly us...

Feb 27, 2025

Carbonate stainless steel test sieve

Carbonate stainless steel test sieves, made from high-quality stainless steel, provide precise and du...

Feb 27, 2025

Feed pellet laboratory sieving machine

Feed pellet laboratory sieving machines, using vibrating standard sieves, accurately analyze particle...

Feb 27, 2025

Small machine powder test sieve

Small machine powder test sieves, utilizing vibration or rotation, provide accurate and efficient par...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap