Brass Test Sieves have sieve surfaces and frames made of brass and are used for laboratory sampling and particle size analysis. It has good mechanical properties, processability, oxidation resistance and corrosion resistance, and good ductility. The heat treatment temperature is between 650-850°C, the annealing temperature is between 600-700°C, and the price is low.

Price: $5-$500Chat Now

Diameter: 200mm

Screen surface: Brass braided mesh

Screen frame: brass skin

Model: 200mm*50mm, 200mm*25mm

Aperture size: 2.36-0.038mm

Height: 50mm

Mesh: 1-500 mesh

About delivery

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

Brass test sieves are a type of laboratory sieve that is made from high-quality brass material. This type of sieve is commonly used in industries such as food processing, agriculture, chemical, and pharmaceutical for particle size analysis. Brass test sieves are specially designed to conform to strict industry standards, ensuring they provide highly accurate results. They feature a smooth surface and are resistant to corrosion, making them suitable for use with a wide range of materials. Additionally, brass sieves are durable and can withstand continuous use, which makes them ideal for use in high-volume production environments.

Model: 200mm*50mm, 200mm*25mm

Diameter: 200mm,300mm

Height: 50mm

Screen Material: Brass

Screen frame material: brass skin

Process: frame punching

Applied materials: used in laboratories and universities for particle size analysis and inspection

Dahan manufacturers can customize brass test sieves of various specifications according to customer requirements.

Brass Test Sieves are widely used in chemical, pharmaceutical, food, light industry, metallurgy and other industries to screen and classify solid granular materials during production and experimentation. Its application materials include powder, granules, liquid substances, etc. In the food industry, Brass Test Sieves can be used to determine the flour content of different particle size levels in flour, determine the distribution of particles of different particle sizes in beverages, and classify the sediment in milk to which particle level. In the pharmaceutical industry, Brass Test Sieves can be used to screen drug raw materials, test particle size in excipients, control particle size distribution in pharmaceutical processes, etc. At the same time, it can also be used in powder metallurgy, ceramic manufacturing, mining and chemical fertilizer industries. The specific materials include sand, aggregate, soil, flour, starch, traditional Chinese medicine powder, grain, coal powder, steel shot, glass powder, etc.

1. Strong corrosion resistance: It has high corrosion resistance, and it is not easy to rust or corrode even if it is used in a humid or acidic environment.

2. Precise sieving: Accurate aperture conforming to ISO 3310-1 / BS410, high mesh precision, able to provide accurate sieving results.

3. High strength and durability: Made of high-strength brass wire, it has excellent durability and long life.

4. Easy to clean: It has a smooth surface and tight mesh, so it is easy to clean and hygienic.

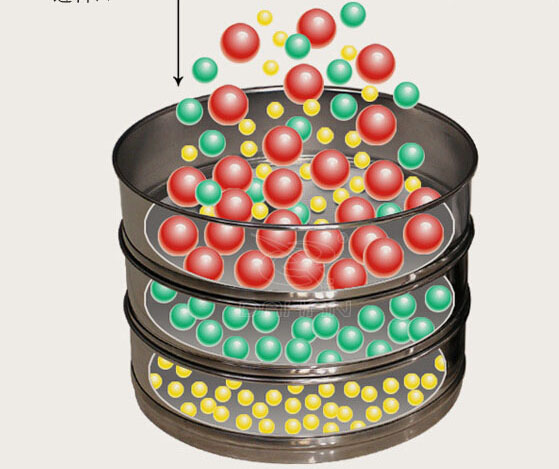

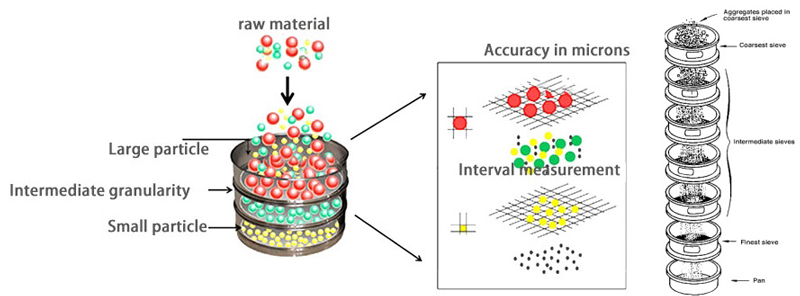

Brass Test Sieves uses YZU vertical vibrating motor as the vibration source of the whole machine. The vibration motor drives the upper vibrating plate to vibrate, and then transmits it to the screen frame on the upper part of the vibrating plate through the vibrating plate. The material particles smaller than the pore size of the screen are screened to the lower screen frame, so that only the same particle size materials are left in each layer of the screen frame, so as to achieve the separation of different particle sizes and determine the particle size composition of this material, so that the particles in the screen frame Materials can be very effective for filtering, grading and screening purposes.

Brass Test Sieves are laboratory sieves made of brass. Brass has the characteristics of corrosion resistance, wear resistance, and good thermal conductivity, so brass laboratory sieves have unique advantages in some special fields.

Food industry: Brass sieves have good corrosion resistance and are not easy to react with food. They are often used for screening food raw materials, such as flour, powdered sugar, etc.

Pharmaceutical industry: Brass sieves are used for screening of traditional Chinese medicine powders, which can effectively remove impurities and ensure the purity of medicinal materials.

Chemical industry: Brass sieves can be used to screen some corrosive chemicals.

Brass test sieves are composed of upper cover, copper screen, the same screen frame, chassis and so on.

| Cassia seed | 14mesh | Buckwheat | 12mesh | Yellow mealworm eggs | 12mesh |

| Insect feces | 30mesh | Soybean | 4-5mesh | Mung beans | 10mesh |

| Rice | 12-14mesh | Rice flour | 30-40mesh | Corn flour | 30-40mesh |

| Flour | 50-60mesh | Whole grains | 40-50mesh | Sesame millet | 22-24mesh |

| Fried chicken hamburger breading | 20-30mesh | Mung bean powder | 40-50mesh | Sesame powder | 40-50mesh |

| Panax notoginseng powder | 100-120mesh | Pine pollen | 100-120mesh | Chinese medicine powder | 40-50mesh |

| Oral Chinese medicine powder | 60-80mesh | Chinese medicine mask | 80-120mesh | Pearl powder | 120-150mesh |

| Medicine residue | 60-150mesh | Soy milk | 80-120mesh | Honey | 80-120mesh |

| Soup residue | 120-150mesh | Tea water | 120-150mesh | Edible oil | 150-200mesh |

| No. | Name | Unit | Parameter |

| 01 | Screen frame | Layer | 1~8 |

| 02 | Screen frame diameter | mm | Φ200 Φ100 Φ75 |

| 03 | Screening particle size | mm | 0.038~5 |

| 04 | Noise | dB | Less than 50 |

| 05 | Amplitude | mm | 0~3 |

| 06 | Vibration frequency | times/min | 1400 |

| 07 | Overall dimensions | Length, width and height | 350:350:300+N*50 |

| 08 | Power supply | V; HZ | 220; 50 |

| 09 | Machine weight | Kg | 36 |

| mesh | Aperture(mm) | mesh | Aperture(mm) | mesh | Aperture(mm) |

| 2 mesh | 12.5 | 45 mesh | 0.4 | 220 mesh | 0.065 |

| 3 mesh | 8 | 50 mesh | 0.355 | 240 mesh | 0.063 |

| 4 mesh | 6 | 55 mesh | 0.315 | 250 mesh | 0.061 |

| 5 mesh | 6 | 60 mesh | 0.28 | 280 mesh | 0.055 |

| 6 mesh | 4 | 65 mesh | 0.25 | 300 mesh | 0.050 |

| 8 mesh | 3 | 70 mesh | 0.224 | 320 mesh | 0.045 |

| 10 mesh | 2 | 75 mesh | 0.2 | 325 mesh | 0.043 |

| 12 mesh | 1.6 | 80 mesh | 0.18 | 340 mesh | 0.041 |

| 14 mesh | 1.43 | 90 mesh | 0.16 | 360 mesh | 0.040 |

| 16 mesh | 1.25 | 100 mesh | 0.154 | 400 mesh | 0.0385 |

| 18 mesh | 1 | 110 mesh | 0.15 | 500 mesh | 0.0308 |

| 20 mesh | 0.9 | 120 mesh | 0.125 | 600 mesh | 0.026 |

| 24 mesh | 0.8 | 130 mesh | 0.112 | 800 mesh | 0.022 |

| 26 mesh | 0.71 | 140 mesh | 0.105 | 900 mesh | 0.020 |

| 28 mesh | 0.68 | 150 mesh | 0.100 | 1000 mesh | 0.015 |

| 30 mesh | 0.6 | 160 mesh | 0.096 | 1800 mesh | 0.010 |

| 32 mesh | 0.58 | 180 mesh | 0.09 | 2000 mesh | 0.008 |

| 35 mesh | 0.50 | 190 mesh | 0.08 | 2300 mesh | 0.005 |

| 40 mesh | 0.45 | 200 mesh | 0.074 | 2800 mesh | 0.003 |

| Brass Test Sieves | stainless steel test sieves | |

| material | Brass (softer metal) | 304/316 stainless steel (strong and durable) |

| color | yellow | silver or off-white |

| price | $5-$500/Set | $20.00-$880.00/Set |

| Features | Spark-proof, good ductility, high thermal and electrical conductivity, not durable | Not easy to rust, resistant to 300℃ high temperature, acid and alkali corrosion, durable |

| diameter | 200mm, 300mm | 75mm, 100mm, 200mm, 300mm, 400mm, 500mm |

| Usage | Will contain lead and grow patina to varying degrees | Acid and alkali corrosion resistance, no release of harmful substances |

| application | Accurate screening and particle size detection of granular materials in abrasive, dikan and metallurgical industries | Dry and wet screening, preferred in the food and pharmaceutical industries |

| service life | short | long |

1. Weigh the sample according to the regulations;

2. Sieve the samples according to the size of the sieve holes;

3. When the thickness of the sieve layer on each sieve is greater than the maximum particle size value of the sample, the sieve residue on the sieve should be divided into two parts, and sieved again until the throughput of each sieve per minute does not exceed 0.1% of the total sample;

4. When the particle size of the sieved particles is greater than 20.0mm, during the sieving process, it is allowed to move the particles with fingers;

5. Weigh the weight of each sieve, which is 0.1% of the total weight of the sample;

6. Compared with the total amount of samples measured before sieving, the difference between the sum of all the sieve remainders on the sieve and the remainder at the bottom of the sieve shall not exceed 1%.

1. Divide the sieve residue on each sieve by the total amount of the sample to calculate the fractional sieve residue percentage (to 0.1%) of this sieve;

2. The calculated residual percentage of each sieve is added to the calculated residual percentage of each sieve larger than the sieve number, and the cumulative residual percentage is calculated (to 1%);

3. According to the cumulative sieve percentage of each sieve, evaluate the particle gradation of the sample.

Dahan Brass Test Sieves Manufacturer For Sale Brass Test Sieves Machine, Metal Braided Mesh Brass Test Sieves, Metal Perforated Plate Brass Test Sieves, Ultrasonic Brass Test Sieves, Electromagnetic Brass Test Sieves, Magnetic Levitation Brass Test Sieves, Slap Brass Test Sieves, Top Impact Brass Test Sieves and other equipment, the models are 75mm, 100mm, 200mm, 300mm, 400mm, etc., the price is as low as $100 for factory direct sales.

Screening particle size: 0.025-3mm

Price: $650.00 - $800.00/Set

Diameter: 200mm

Price: $20.00-$200.00/Set

Mesh size: 2.36mm-0.038mm

Price: $10.00-$200.00/Set

Test range: 20µm-125mm

Price: $15-$620

What is brass test sieve used for?

Brass test sieve is a type of sieve that is widely used in various industries including agriculture, food and beverage, pharmaceuticals, cosmetics, and more. ...

Pharmacopoeial sieves (standard pharmacopoeial sieves) refers to the sieves used for pharmaceutical production according to the national uniform specifications stipulated in the Pha...

Application of wet sieve test screening material

In many cases, wet sieve test sieving, despite the inconveniences that come with it, has clear advantages over dry sieving. For example, the material to be tested may have been susp...

What is the difference between wet sieving and dry sieving

The sieving test is divided into wet sieving test and dry sieving test, so what is the difference between wet sieving and dry sieving? difference Wet sieving test Dry sieving test i...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap