Thursday February-27 2025 12:17:56

Baking powder test sieve is a special screening device used to detect the particle size distribution of baking powder (such as flour, powdered sugar, cocoa powder, etc.). It classifies the powder sample by particle size through the aperture size of the sieve, thereby evaluating the fineness and uniformity of the powder to ensure that it meets the quality requirements of baked products. This test sieve is usually used in laboratories or production sites for particle size analysis and particle screening of powder materials.

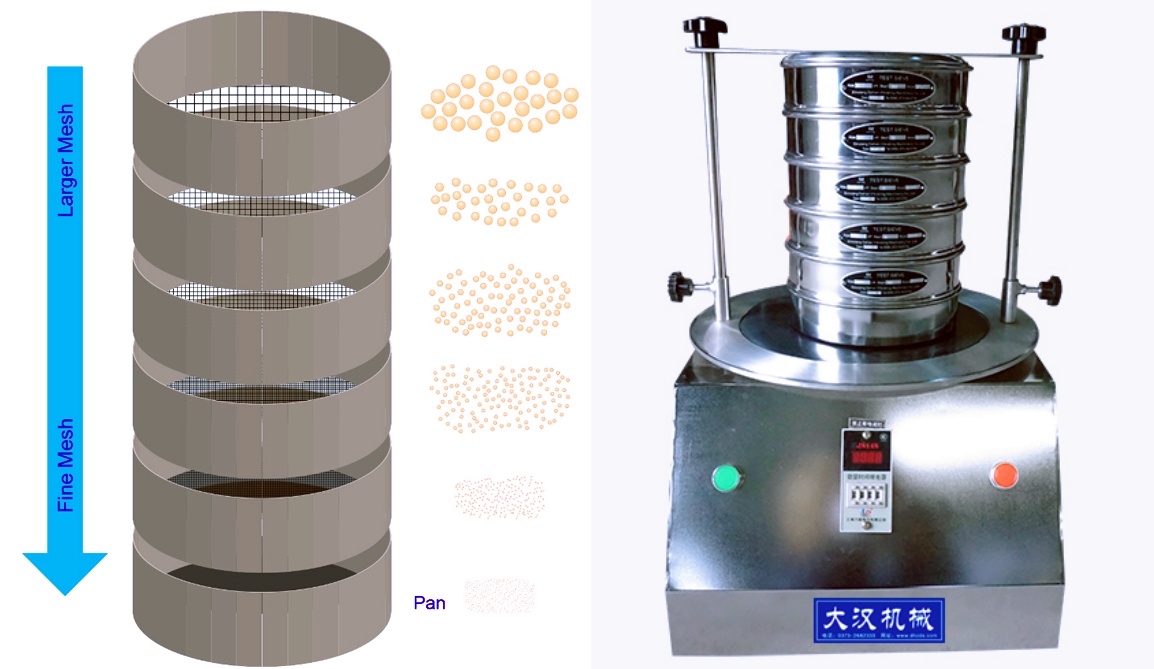

The working principle of the baking powder test sieve is similar to that of a general vibrating sieve. The baking powder sample is placed on the sieve, and then the vibration force generated by the vibrating device (such as a vibrating motor) causes the baking powder to be sieved on the sieve. Finer baking powder particles will pass through the pores of the sieve, while larger baking particles will be blocked, thereby achieving the grading and sieving of baking powder.

Particle size analysis: Determine the particle size distribution of the baking powder to provide data support for formula optimization.

Impurity removal: Screen out impurities in the baking powder, such as pebbles, metal fragments, etc., to improve product purity.

Improve baking effect: Powders of different particle sizes have different effects on baking effects, and the best baking effect can be obtained through sieving.

1. Screen material: corrosion-resistant and wear-resistant stainless steel is used to prevent the screen from being corroded or worn, extending its service life.

2. Vibration mode: low-frequency, high-amplitude vibration mode is used to effectively prevent the flying and clogging of fine powder, while ensuring high screening efficiency.

3. Sealing design: The sealing design is adopted to prevent dust leakage, protect the health of operators, and keep the laboratory environment clean.

4. Multi-layer screen design: multi-layer screens can be set according to different screening requirements to achieve multi-level screening and improve screening accuracy.

5. Quick disassembly: The screen is easy to disassemble and install, and is easy to clean and replace.

Comparison between baking powder test sieve and other test sieves

Screen material usually stainless steel, corrosion-resistant and wear-resistant select according to material characteristics

Vibration mode low frequency, high amplitude, to prevent dust flying various vibration modes

Sealing good sealing, to prevent dust leakage relatively low sealing requirements

Number of screen layers can be stacked in multiple layers to improve screening accuracy fewer layers

Flour industry: sieve out impurities in flour and improve the purity of flour.

Baking raw material industry: sieve various baking raw materials to ensure uniform particle size.

Food additive industry: sieve food additives to improve product quality.

Product development: When developing new products or improving existing products, baking powder test sieves can be used to evaluate the particle characteristics of different raw materials, select the most suitable raw material combination, and improve product quality and market competitiveness.

Visual inspection: First, check whether the appearance of the test sieve is intact and whether the sieve is damaged or deformed. Ensuring that the sieve has no gaps or deformation can ensure the accuracy of sieving.

Sieve size verification: Use appropriate tools to measure the sieve size on the test sieve. The baking powder test sieve usually has a precise sieve size, and different specifications of sieves can be selected for testing as needed. By sieving and grading the powder sample, the particle size distribution of the powder can be obtained, thereby guiding production and quality control.

Screening efficiency test: prepare a standard particle sample, put it into the test sieve, and start the vibration equipment for screening. Screening is carried out according to the standard procedure, and the number of particles passing and blocked is recorded. The screening efficiency is evaluated by comparing the actual results with the expected results.

Repeatability test: perform multiple screening tests to check the repeatability and consistency of the test sieve. If the results of multiple tests are consistent, it means that the effect of the test sieve is stable and reliable.

Cleaning and maintenance: clean and maintain the test sieve regularly to ensure that the sieve is clean and unblocked and the vibration equipment works normally. Keeping the test sieve clean and in good condition can extend its service life and ensure accurate test results.

Baking powder test sieve plays an important role in the research and production process of powder materials, which can help users evaluate the physical properties and quality of powders, as well as optimize production processes.

laboratory test sieve is also called standard sieve, test sieve, laboratory vibrating screen, sample sieve, inspection sieve, standard analysis sieve...

What Is An Electromagnetic Sieve Shaker?

Electromagnetic sieve shaker is a screening equipment used for testing and laboratory research. It is often used to screen and classify small batches...

Test sieve shaker is a laboratory equipment used for particle screening and classification, also known as laboratory shaker or laboratory vibrating...

Feb 27, 2025

Baking powder test sieve is used to detect the distribution of powder particle size and evaluate the ...

Feb 27, 2025

Liquid food test sieves are used to screen solid particles, impurities or extract required ingredient...

Feb 27, 2025

Plastic granule test sieve is a device specially used for screening and grading plastic granules. It ...

Feb 27, 2025

304 stainless steel soil test sieve

304 stainless steel soil test sieves are essential tools for accurate soil particle size analysis. Ma...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap