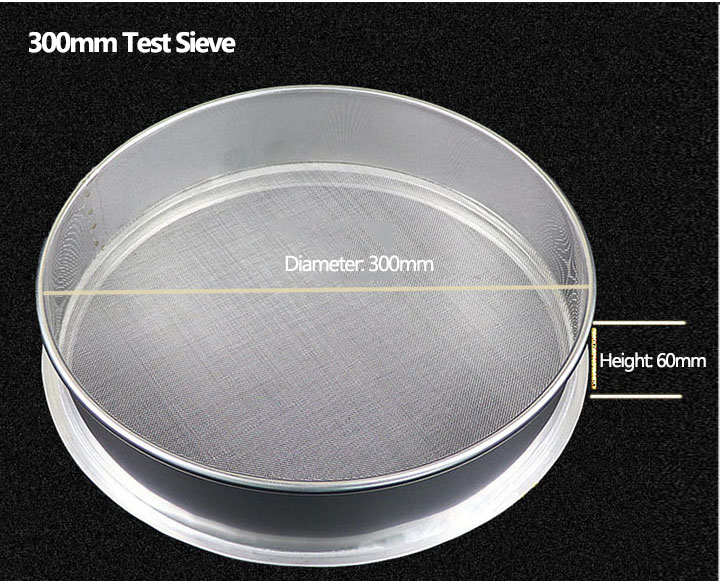

300mm Test Sieve is a stainless steel precision test sieve with a diameter of 300mm. The sieve is produced according to the GB6003.1-1997 standard. , Particle size analysis of granular materials.

Model: 300×60 Chat Now

Screen frame diameter: 300mm

Height: 6cm

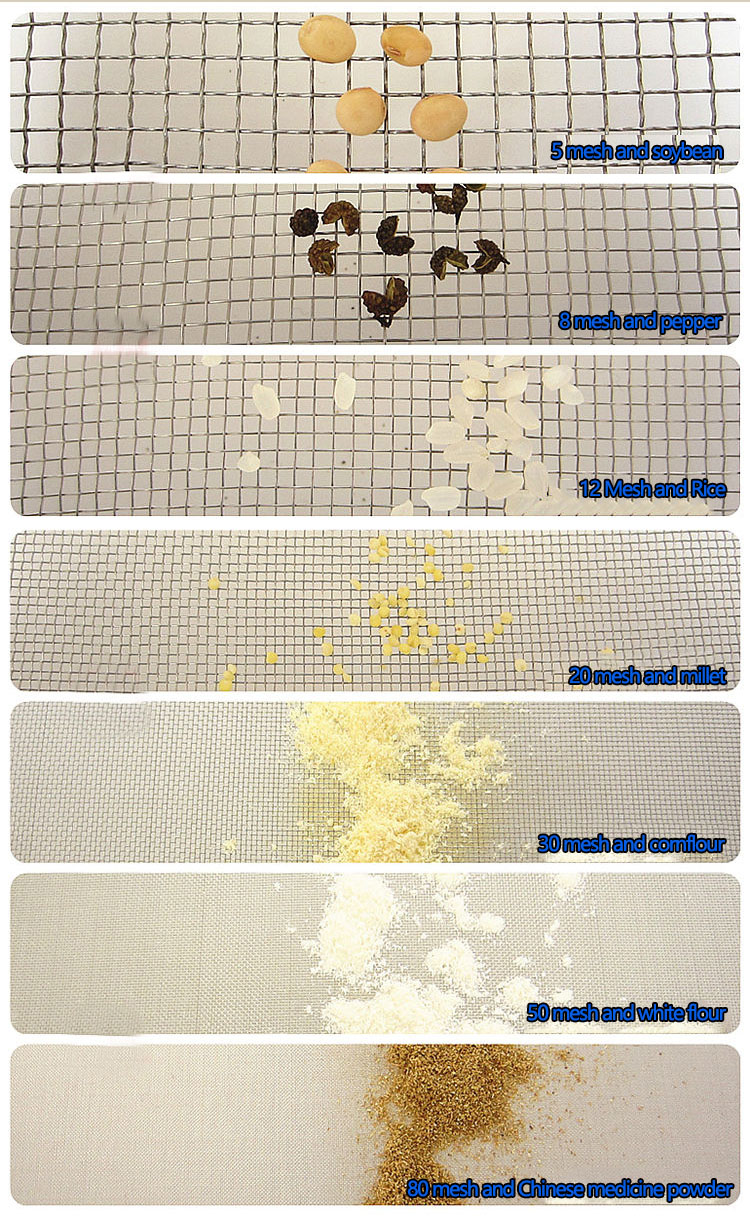

Screen mesh: commonly used 40, 50, 60, 70, 80, 100, 120 mesh (2 mesh-2800 mesh can be customized)

Materials: grain, abrasive, aggregate, traditional Chinese medicine powder, cement powder, soil, alloy powder, iron powder, graphite powder, etc.

1. Comply with international standard ISO3310-1:1990 R20/3, R20, R40/3 series

2. Noise level ≤50dB, will not interfere with the laboratory environment, suitable for long-term use.

3. The equipment is equipped with a timing controller, which can accurately control the screening time, save time, and ensure the repeatability of the test. The one-time feeding amount is ≤200g, which is suitable for screening small batch samples in the laboratory.

| Quantity (set) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

300mm Test Sieve is a stainless steel precision test sieve produced by Dahan Machinery, which can be used in the laboratory for particle size analysis of powder/granule/material and content detection of liquid material; the sieve conforms to the national standard GB6003.1-1997 and is selected by a tool microscope; 300mm Test Sieve has metal woven screens, perforated plate screens and electroformed screens with mesh size from 0.038mm to 2.36mm. Our company adopts the marking method of mesh/wire diameter for the specifications (because the mesh number is a relative unit, the mesh number refers to the number of holes and wires on the length of 1 inch 25.4 mm. The same mesh number, different wire diameters, and different holes).

Chinese medicine powder screening

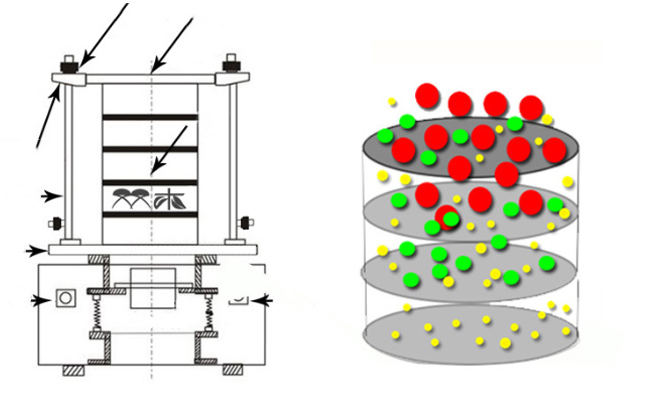

The vibration generated by the vibration motor causes the screen frame and the material on the screen to move relative to each other. The material particles smaller than the screen aperture will pass through the screen and fall into the lower screen frame, while the material particles larger than the screen aperture will remain on the screen, thus achieving separation of different particle sizes.

300mm test sieve is a commonly used laboratory screening equipment. It is mainly composed of a screen frame, a screen mesh, a screen bottom, a clamping device and a vibration motor. The screen frame is usually made of stainless steel, which is corrosion-resistant and high-temperature resistant. A fixing device is provided on the top of the screen frame to firmly fix the screen mesh. The screen mesh is the core component of the screening, and the material is diverse, such as stainless steel woven mesh and punched plate, etc. Screens of different apertures can be selected according to the screening needs.

Prevent clogging: 300mm standard test sieve usually has a suitable mesh size and design, which can effectively prevent particles from clogging in the mesh and keep the screening unobstructed.

Accurate screening ability: 300mm standard test sieve has a high-precision mesh size, which can accurately screen particles of different particle sizes and provide accurate particle analysis data.

Dust control: The test sieve is usually designed with a dust sealing device to reduce the flying of dust, keep the experimental environment clean, and protect the health of the operator.

Efficiency: Through the multi-layer screen design and precise screening mechanism, the 300mm standard test sieve can improve screening efficiency and save experimental time.

300mm Test Sieve is used for the particle size detection of powder and granular materials in the laboratory and the determination of solid-liquid content in liquids; common materials include: iron powder, soil, feed, abrasive, alloy powder, resin, plastic particles, flour, coal, White lime, glass powder, activated carbon, ceramic powder, mud, magnesium oxide, etc.

| Particles | powder | Liquid | special class |

| Soybeans: 5 mesh | Fried chicken breaded: 10 mesh-30 mesh | Soymilk: 60-100 mesh | Tenebrio molitor eggs: 12 orders |

| Mung beans: 10 mesh | Cornmeal: 30 mesh | Honey: 60 mesh-100 mesh | Tenebrio molitor droppings: 30 mesh |

| Buckwheat: 12 mesh | Multigrain powder: 30 mesh -40 mesh | Chinese medicine residue: 80 mesh -150 mesh | Sand painting: 80 mesh-120 mesh |

| Rice: 12-14 mesh | Wheat flour: 50 mesh | Soup dregs: 80 mesh-150 mesh | Edible oil residue: 100 mesh-180 mesh |

| Black rice: 14 mesh | Chinese medicine powder: 60 months-100 mesh | Edible oil residue: 100 mesh-180 mesh | |

| Millet: 24 mesh | Chinese herbal mask powder: 100-120 mesh | ||

| Sesame: 24 mesh | Pearl powder: 120-150 mesh | ||

| Pepper seeds: 8-10 mesh | Panax notoginseng powder: 120 mesh-180 mesh | ||

| Material size, variety, fineness, integrity, viscosity, required effect, and filtration speed all affect the choice of mesh number! (Mesh number recommendation is for reference only) | |||

As a commonly used laboratory equipment, 300mm test sieve plays an important role in many fields.In the agricultural field, it is used to screen seeds, remove impurities and broken seeds and soil samples, and analyze the particle size composition. In the scientific field, it is used to screen various material powders, study the microstructure and properties of materials, and can also be used to screen soil and water samples, etc., and analyze environmental pollutants.

Wire woven mesh: mesh size between 2.36mm and 0.02mm, square mesh, commonly used, low price.

Perforated plate screen: the mesh size ranges from 0.2 to several hundred millimeters. There are two types of round hole and square hole screen. It is mainly used for large meshes and is often used for the detection of large particle materials such as soil, asphalt, and coal.

Electroforming screen: the precision can reach 1 micron, mainly used in high-precision occasions in the laboratory, and each mesh can be within the average error range. As a professional manufacturer of standard sieves, it is necessary to have a tool microscope and a projector. The tool microscope is used to check the accuracy of the mesh, and the arithmetic mean method is used.

The sieve size of the sieve produced by Dahan Machinery guarantees the same type of 300mm Test Sieve, and the meshes produced at different times are the same to ensure the consistency of the test and detection. The hole size of the imported Taylor screen is similar to that of GB6003.1-1997. For example, the mesh size of No. 140 in China is 106 microns; the mesh size of No. 140 # Taylor screen in the United States is 105 microns; the mesh size is 105 microns; make.

| serial number | name | Specification |

| 1 | New standard gravel screen (φ300, 7 pcs/set+bottom cover) | 9.50、4.75、2.36、1.18、600um、300um、150um |

| 2 | New standard gravel sieve (φ300 12pcs/set+bottom cover) | 2.36、4.75、9.50、16.0、19.0、26.5、31.5、37.5、53.0、63.0、0.75、90.0mm |

| 3 | Pavement primary aggregate screen (φ200, 300, 11 pieces/set + bottom cover) 40, 50 | 0.075、0.25、0.5、1、2、5、10、20、30、40、50 |

| 4 | bitumen aggregate square hole screen | 0.075、0.15、0.3、0.6、1.18、2.36、4.75、9.5、13.2、16、19、26.5、31.5、53mm |

| 5 | New standard square hole sieve φ200×50mm6pcs/set | Iron plate square hole: 4.75, 9.5, 13.2, 16, 19, 26.5, 31.5, 37.5, 53mm; |

| Screen square hole: 0.075, 0.15, 0.3, 0.6, 1.18, 2.36 | ||

| 6 | Punching frame sand screen (casting screen) φ200 (11 pieces/set) | 3.35、1.7、0.85、0.6、0.425、0.3、0.212、0.15、0.106、0.075、0.53mm |

| 7 | Pavement square hole aggregate screen | 80、60、50、40、30、25、20、10、5、2、1、0.5、0.2、0.075mm |

| 8 | Asphalt pavement aggregate screen (φ200, 300, 15pcs/set+bottom cover) | 0.075、0.15、0.3、0.6、1.18、2.36、4.75、53mm |

| 9 | Gravel sieve φ200×50 (8 pieces/set) | Iron plate round hole 10, 5 |

| Square hole copper mesh 2.5, 1.25, 0.63, 0.315, 0.16, 0.08 | ||

| 10 | Stone sieve φ300×70mm (12 pieces/set) | 2.5、5、10、16、20、25、31.5、40、50、63、80、100mm |

| 11 | Lime sieve (φ200 5pcs/set+bottom cover) | 0.125、0.71、0.9、5、20 |

| 12 | New Standard Pharmacopoeia Sieve φ200×50mm (9 pcs/set) | 2、0.85、0.355、0.25、0.18、0.15、0.125、0.09、0、075mm |

| 13 | Stone special sieve | 2.5, 5, 10, 16, 20, 25, 31.5, 40, 50, 63, 80, 100, bottom cover or 2.36, 4.75, 9.5, 16, 19, 26.5, 31.5, 37.5, 53, 63, 75, 90. Bottom cover |

| 14 | Special sieve for sand | 0.08, 0.16, 0.315, 0.63, 1.25, 2.5, 5, 10, with bottom cover or 0.075, 0.15, 0.3, 0.6, 1.18, 2.36, 4.75, 9.5, with bottom cover |

| 15 | Soil special sieve | 0.074, 0.25, 0.5, 1, 2, 5, 10, 20, 40, 60, with bottom cover |

| 16 | For asphalt | 0.075, 0.15, 0.3, 0.6, 1.18, 2.36, 4.75, 9.5, 13.2, 16, 19, 26.5, 31.5, 37.5, 53, bottom cover |

| Mesh basic size w | Wire diameter d | Screening area percentage A0% | Basic size of sieve hole | Wire diameter d | Screening area percentage A0% | ||||

| Main dimensions | supplementary size | Main dimensions | supplementary size | ||||||

| R20/3 | R/20 | R40/3 | R20/3 | R/20 | R40/3 | ||||

| 900 | 500 | 41 | 180 | 180 | 180 | 125 | 35 | ||

| 850 | 500 | 40 | 160 | 112 | 35 | ||||

| 800 | 450 | 41 | 150 | 100 | 36 | ||||

| 710 | 710 | 710 | 450 | 37 | 140 | 100 | 34 | ||

| 630 | 400 | 37 | 125 | 125 | 125 | 90 | 34 | ||

| 600 | 400 | 36 | 112 | 80 | 34 | ||||

| 560 | 355 | 37 | 106 | 71 | 33 | ||||

| 500 | 500 | 500 | 315 | 38 | 100 | 71 | 34 | ||

| 450 | 280 | 38 | 90 | 90 | 90 | 63 | 35 | ||

| 425 | 280 | 36 | 80 | 56 | 35 | ||||

| 400 | 250 | 38 | 75 | 50 | 36 | ||||

| 355 | 355 | 355 | 224 | 38 | 75 | 50 | 34 | ||

| 315 | 200 | 37 | 63 | 63 | 63 | 45 | 34 | ||

| 300 | 200 | 36 | 56 | 40 | 35 | ||||

| 280 | 180 | 37 | 53 | 36 | 35 | ||||

| 250 | 250 | 250 | 160 | 37 | 50 | 36 | 34 | ||

| 224 | 160 | 34 | 45 | 45 | 45 | 32 | 35 | ||

| 212 | 140 | 36 | 40 | 32 | 31 | ||||

| 200 | 140 | 35 | 38 | 30 | 31 | ||||

The so-called mesh number of 300mm Test Sieve refers to the particle size or thickness of the material. The general definition refers to the sieve within the area of 1 inch*1 inch. The material can pass through the sieve, and the number of holes in the sieve is defined as the mesh number. . For example, 200 mesh means that the material can pass through a screen with 200 meshes within 1 inch*1 inch. By analogy, the larger the mesh number, the finer the particle size of the material; the smaller the mesh number, the larger the particle size of the material. The sieving particle size is the size of the sieve holes that the particles can pass through the sieve, expressed as the number of sieve holes in a 1-inch (25.4mm) wide sieve, so it is called the mesh number.

| Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) |

| 2 | 13 | 26 | 0.71 | 90 | 0.16 | 260 | 0.06 |

| 3 | 6.5 | 28 | 0.63 | 100 | 0.154 | 280 | 0.055 |

| 4 | 5 | 30 | 0.6 | 110 | 0.14 | 300 | 0.054 |

| 5 | 4 | 32 | 0.55 | 115 | 0.13 | 320 | 0.048 |

| 6 | 3.2 | 36 | 0.5 | 120 | 0.125 | 325 | 0.045 |

| 7 | 2.8 | 40 | 0.45 | 130 | 0.111 | 350 | 0.041 |

| 8 | 2.5 | 45 | 0.4 | 140 | 0.105 | 360 | 0.4 |

| 9 | 2.2 | 50 | 0.355 | 150 | 0.1 | 400 | 0.0385 |

| 10 | 2 | 55 | 0.315 | 160 | 0.098 | 500 | 0.03 |

| 12 | 1.6 | 60 | 0.3 | 180 | 0.09 | ||

| 14 | 1.43 | 65 | 0.25 | 190 | 0.08 | ||

| 16 | 1.25 | 70 | 0.22 | 200 | 0.075 | ||

| 18 | 1 | 75 | 0.2 | 220 | 0.07 | ||

| 20 | 0.9 | 80 | 0.18 | 240 | 0.065 | ||

| 24 | 0.8 | 85 | 0.17 | 250 | 0.063 |

The price of Dahan standard screen is between 2.74-822 dolla, and its specific price is related to the material, model, specification and purpose.

Screen frame materials include stainless steel (starting from 16.44 dolla), brass (starting from 27.4 dolla), nylon (starting from 8.22 dolla).

Standard screen model: 75mm (starting from 20.55 dolla), 100mm (starting from 34.25 dolla), 200mm (starting from 38.1 dolla), 300mm (starting from 61.65 dolla).

The specifications and uses of the standard sieve need to be determined according to the actual use scenario and materials, and the specific price is subject to the actual situation.

As a universal screening equipment, the 300mm test sieve has been widely used in many fields such as agriculture and scientific research. Its simplicity, high efficiency and high precision make it an essential tool in laboratories and production lines. With the development of science and technology, the performance of the 300mm test sieve will continue to improve, providing more accurate screening services for more fields.

300mm Test Sieve Supporting Standard Operation Steps

300mm Test Sieve is mainly used for filtering and testing the particle size structure of granular and powdery materials, the content of liquid solids and the amount of debris. It is...

Standard Soil Sieve Sizes and Specifications

Standard Soil Sieve is a tool for detecting the particle size distribution and analysis of soil particles larger than 0.075mm in diameter. Standard Soil Sieve Sizes mesh Aperture(...

Which is better, Gear type Slap Sieve or Belt type Slap Sieve?

The Gear-type Slap Sieveis installed on a horizontal foundation with anchor bolts, and the circuit and grounding are installed according to electrical regulations. The Gear-type Sla...

Slap Type Test Sieve Selection Notes

1. Clarify the purpose of your purchase If you are buying for a laboratory, you must require a standard sieve with exquisite appearance, beautiful appearance and fast mesh, which ha...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap