20cm Test Sieve refers to a sieving equipment commonly used in laboratory research or quality inspection, with a sieve diameter of 20cm; it is used for particle analysis and sieving tests, and is often used in geotechnical, cement, ceramics, chemicals, food, In the pharmaceutical and other industries.

Diameter: 20cm (7.9 inches) Chat Now

Height: 50cm

Screening particle size: 0.036-2mm

Material: stainless steel, brass

Materials: mineral powder, cement, fly ash, starch, coal, sand, grain, etc.

1. Strong portability: The diameter of 20cm makes the test sieve moderate in size, easy to operate and move, and is suitable for various laboratory environments.

2. Moderate sample size: It can accommodate a sufficient amount of samples for testing without being too large to affect the screening efficiency.

3. Universally suitable for routine laboratory screening and particle size analysis, with high cost performance.

A 20cm Test Sieve is a type of laboratory equipment used for particle size analysis. It is made up of a woven wire mesh with precise openings or slots that allow particles of certain sizes to pass through while retaining larger particles. The test sieves come in different sizes, typically ranging from 3-18 inches in diameter. The 20cm test sieve is one of the most commonly used sizes, providing efficient separation of particles in granular or powdered substances. They are widely used in industries such as agriculture, construction, mining, and environmental testing to ensure consistency in particle sizes for quality control and product development.

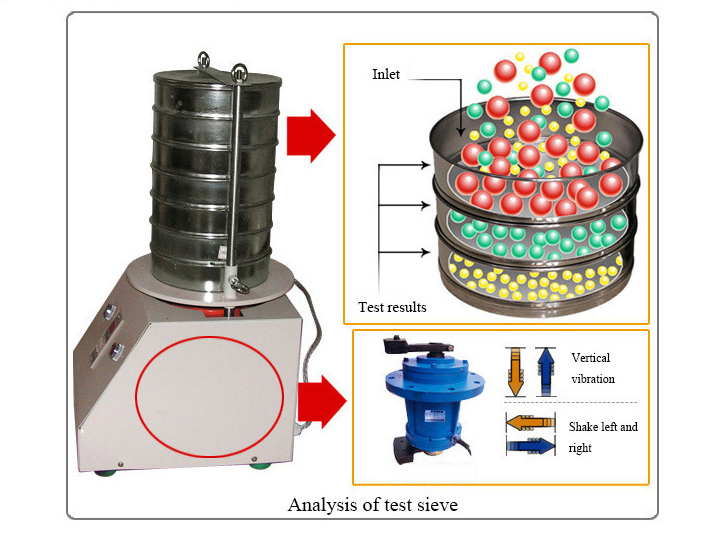

The material is placed on the screen, and the test sieve is vibrated through a mechanical vibration device. During the vibration process, particles smaller than the sieve hole size will fall through the sieve hole, while particles larger than the sieve hole size will remain on the screen, thereby achieving material screening. For example, when a soil sample is sieved, fine-grained clay and silt will pass through the sieve holes, while coarse-grained gravel and sand will remain on the sieve, allowing the particle size distribution of the soil to be analyzed.

20cm test sieve is usually used in laboratories and research institutions for screening tests and analysis of granular materials. This kind of test sieve is mainly used for sieving small batches of samples, and can classify and separate particles quickly and accurately.

The 20cm Test Sieve is mainly used in the laboratory field, and is widely used in materials engineering, chemical industry, medicine, food, mining, metallurgy, environmental protection and other industries. The specific application areas are as follows:

1. Chemical industry: used for screening and classifying granular materials, such as screening analysis of granular materials, measurement of particle size, etc.

2. Food industry: used for screening tests of granular materials such as food raw materials and additives, such as particle size analysis of flour, powdered sugar, etc.

3. Pharmaceutical industry: used for screening tests and particle analysis of granular materials such as medicinal materials and medicinal powders, such as measurement of medicinal particle size.

4. Agricultural field: used for screening tests of agricultural product granular materials, such as seeds, fertilizers and other granular materials.

5. Materials science research: used for screening tests and analysis of material particles, such as particle analysis, material characterization and other research work in the field of powder metallurgy.

6. Environmental science research: used for screening tests of soil samples and wastewater granular materials, such as particle size distribution analysis of granular materials.

1. Larger surface area: A 20cm Test Sieve has a larger surface area compared to smaller sized sieves, allowing for more efficient sieving in a shorter period of time.

2. High accuracy: made to a higher standard, which translates to higher accuracy and more consistent results when analyzing samples.

3. Durable: made from high-quality materials such as stainless steel, ensuring they can withstand heavy usage in industrial settings without deformation or damage.

4. Versatile: can filter out the finest particles, making them suitable for use in a wide range of applications such as pharmaceuticals, food testing, and mineralogy.

| Material | Mesh | Aperture (mm) | Wire DIA. (mm) | Screen%) |

| Stainless steel plate | 5# | 4.00 | 1.00 | 64 |

| 10# | 2.00 | 0.50 | 64 | |

| 20# | 0.85 | 0.315 | 53.2 | |

| 30# | 0.6 | 0.25 | 49.8 | |

| 40# | 0.425 | 0.16 | 52.8 | |

| 50# | 0.3 | 0.14 | 46.5 | |

| 60# | 0.25 | 0.125 | 44.4 | |

| 70# | 0.212 | 0.125 | 39.6 | |

| 80# | 0.18 | 0.125 | 34.8 | |

| 90# | 0.16 | 0.10 | 37.9 | |

| 100# | 0.15 | 0.10 | 36 | |

| 200# | 0.075 | 0.05 | 36 | |

| 300# | 0.048 | 0.036 | 32.7 | |

| 400# | 0.038 | 0.028 | 33.1 | |

| 500# | 0.028 | 0.023 | 27.9 | |

| 600# | 0.02 | 0.02 | 25 | |

| 800# | 0.015 | 0.018 | 23 | |

| 1000# | 0.010 | 0.015 | 20 |

| Sieve size (mm) | American Standard | Tyler Standard | 20cm test sieve | |||||

| Brass frame/brass network cable | SS frame/SS network cable | Brass frame/SS screen | ||||||

| Full Height | Half Height | Full Height | Half Height | Full Height | Half Height | |||

| 2.36 | No. 8 | 8 Order | 59980-00 | 59981-00 | 59984-00 | 59985-00 | 59940-00 | 59941-00 |

| 2 | No. 10 | 9 Order | 59980-01 | 59981-01 | 59984-01 | 59985-01 | 59940-01 | 59941-01 |

| 1.7 | No. 12 | 10 Order | 59980-02 | 59981-02 | 59984-02 | 59985-02 | 59940-02 | 59941-02 |

| 1.4 | No. 14 | 12 Order | 59980-03 | 59981-03 | 59984-03 | 59985-03 | 59940-03 | 59941-03 |

| 1.18 | No. 16 | 14 Order | 59980-04 | 59981-04 | 59984-04 | 59985-04 | 59940-04 | 59941-04 |

| 1 | No. 18 | 16 Order | 59980-05 | 59981-05 | 59984-05 | 59985-05 | 59940-05 | 59941-05 |

| 0.85 | No. 20 | 20 Order | 59980-06 | 59981-06 | 59984-06 | 59985-06 | 59940-06 | 59941-06 |

| 0.71 | No. 25 | 24 Order | 59980-07 | 59981-07 | 59984-07 | 59985-07 | 59940-07 | 59941-07 |

| 0.6 | No. 30 | 28 Order | 59980-08 | 59981-08 | 59984-08 | 59985-08 | 59940-08 | 59941-08 |

| 0.5 | No. 35 | 32 Order | 59980-09 | 59981-09 | 59984-09 | 59985-09 | 59940-09 | 59941-09 |

| 0.425 | No. 40 | 35 Order | 59980-10 | 59981-10 | 59984-10 | 59985-10 | 59940-10 | 59941-10 |

| 0.355 | No. 45 | 42 Order | 59980-11 | 59981-11 | 59984-11 | 59985-11 | 59940-11 | 59941-11 |

| 0.3 | No. 50 | 48 Order | 59980-12 | 59981-12 | 59984-12 | 59985-12 | 59940-12 | 59941-12 |

| 0.25 | No. 60 | 60 Order | 59980-13 | 59981-13 | 59984-13 | 59985-13 | 59940-13 | 59941-13 |

| 0.212 | No. 70 | 65 Order | 59980-14 | 59981-14 | 59984-14 | 59985-14 | 59940-14 | 59941-14 |

| 0.18 | No. 80 | 80 Order | 59980-15 | 59981-15 | 59984-15 | 59985-15 | 59940-15 | 59941-15 |

| 0.15 | No. 100 | 100 Order | 59980-16 | 59981-16 | 59984-16 | 59985-16 | 59940-16 | 59941-16 |

| 0.125 | No. 120 | 115 Order | 59980-17 | 59981-17 | 59984-17 | 59985-17 | 59940-17 | 59941-17 |

| 0.106 | No. 140 | 150 Order | 59980-18 | 59981-18 | 59984-18 | 59985-18 | 59940-18 | 59941-18 |

| 0.09 | No. 170 | 170 Order | 59980-19 | 59981-19 | 59984-19 | 59985-19 | 59940-19 | 59941-19 |

| 0.075 | No. 200 | 200 Order | 59980-20 | 59981-20 | 59984-20 | 59985-20 | 59940-20 | 59941-20 |

| 0.063 | No. 230 | 250 Order | 59980-21 | 59981-21 | 59984-21 | 59985-21 | 59940-21 | 59941-21 |

| 0.053 | No. 270 | 270 Order | 59980-22 | 59981-22 | 59984-22 | 59985-22 | 59940-22 | 59941-22 |

| 0.045 | No. 325 | 325 Order | 59980-23 | 59981-23 | 59984-23 | 59985-23 | 59940-23 | 59941-23 |

| 0.038 | No. 400 | 400 Order | 5998024 | 59981-24 | 59984-24 | 59985-24 | 59940-24 | 59941-24 |

1. Sieve placement and connection: The 20cm test sieve must be placed horizontally to ensure stability and uniformity during the screening process. Any tilt may lead to inaccurate screening results. Check whether the power connection meets the requirements and ensure that the power voltage is stable and meets the rated voltage requirements of the screen.

2. Screen frame selection and installation: Select an appropriate screen frame according to the properties and size of the material. Different materials may require screens with different apertures and materials to ensure screening effects. The sizes of the screen frame apertures are stacked in order from small to large and from bottom to top. This ensures that materials pass step by step during the screening process and prevents large particles from clogging the small-aperture screen. After stacking the screen frames, increase the height of the control rod according to the total height of the screen frames, and use the pressure plate and locking nut to position and tighten the standard screen frame. Pay attention to the uniform force on both sides to prevent the screen frame from deforming or loosening.

3. Material placement and screening: Put the test material into the uppermost sieve frame. Pay attention to the appropriate amount to avoid incomplete screening due to too much or too little affecting the screening efficiency. Set the appropriate running time on the timer according to the nature of the material and the amount of feed. Running time that is too long or too short may affect the screening results. Start the test sieve and start working. Pay attention to the situation during the screening process. If there is any abnormality, stop it for inspection in time.

4. Post-screening treatment: The screened particles will fall into the base or chassis and should be collected in time for further analysis or processing. After screening, clean the residual materials on the screen in time to prevent clogging the screen holes or affecting the next screening effect. Pay special attention to cleaning the impurities in the sieve holes to ensure that the sieve holes are unobstructed.

What are the industrial applications of sieve shaker?

The industrial applications of sieve shaker include: 1. Particle size analysis: Sieve shaker is extensively used in industries for particle size analysis of various materials such a...

Laboratory Sieve Shaker Machine Price

Laboratory Sieve Shaker Machine Price:$150.00 - $980.00/Set Laboratory sieve shaker machines are used extensively in chemical and physical laboratories to separate different particl...

What is brass test sieve used for?

Brass test sieve is a type of sieve that is widely used in various industries including agriculture, food and beverage, pharmaceuticals, cosmetics, and more. These sieves are primar...

What is the aperture size of sieve 10?

Sieve 10 is a standard testing sieve used in the particle size analysis of various materials. The aperture size of sieve 10 refers to the size of the openings or holes on the sieve....

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap